Technology for determining coal bed intensity by using coal ash

A strength and coal seam technology, applied in the direction of wellbore/well components, earth cube drilling and mining, etc., can solve the problems of coal seam coring difficulty in coal bed methane drilling, unsuitable for coal seam drilling strength prediction, etc., and achieve good application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

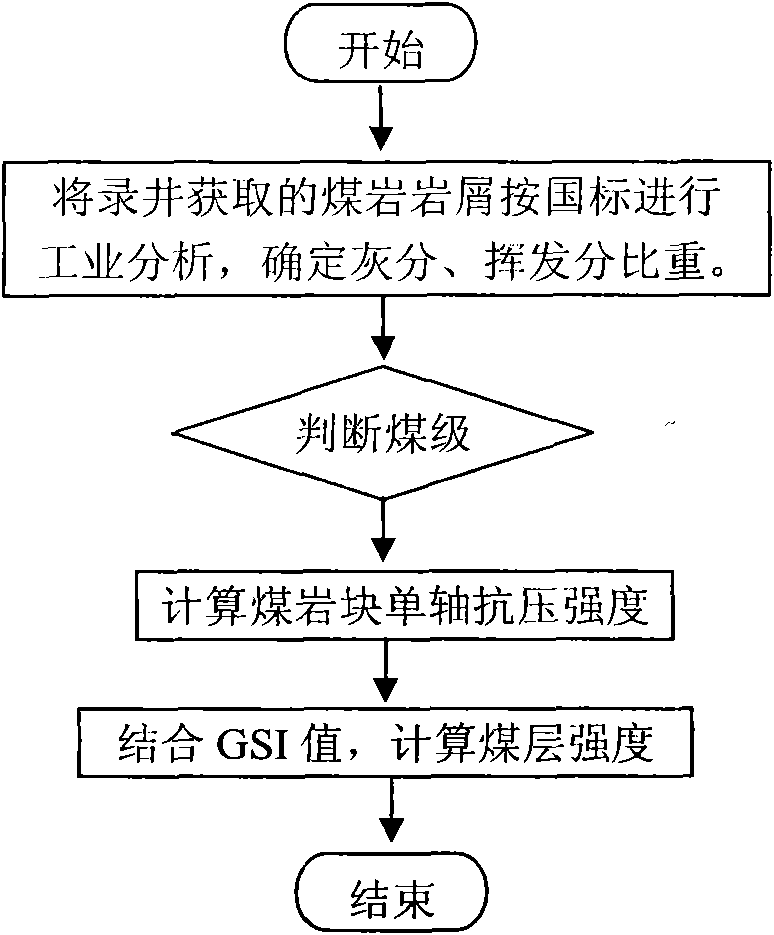

[0027] The method for determining coal seam strength with coal ash proposed by the present invention is described as follows in conjunction with accompanying drawings and examples.

[0028] Due to the particularity of the coal seam structure, the development of various cracks in the coal rock leads to its mechanical properties: discontinuity, heterogeneity, anisotropy and permeability, which make the mechanical strength of the coal seam low, and the cracks and cleats are developed. The homogeneity is poor, drilling and coring is difficult, and it is difficult to process standard test coal cores after the cores are subjected to stress release, mechanical disturbance, and water loss. The results of the indoor strength test are seriously distorted.

[0029] At present, the prediction of coal seam strength at home and abroad is mostly based on the strength prediction after the artificial geological conditions of coal mine roadway wall cracks. However, it is difficult to take cores...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com