Three-dimensional stress fluid coupling grouting test system and method

A grouting test, three-dimensional stress technology, applied in soil material testing, material inspection products, etc., can solve the problems of long cycle, complicated operation, poor environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

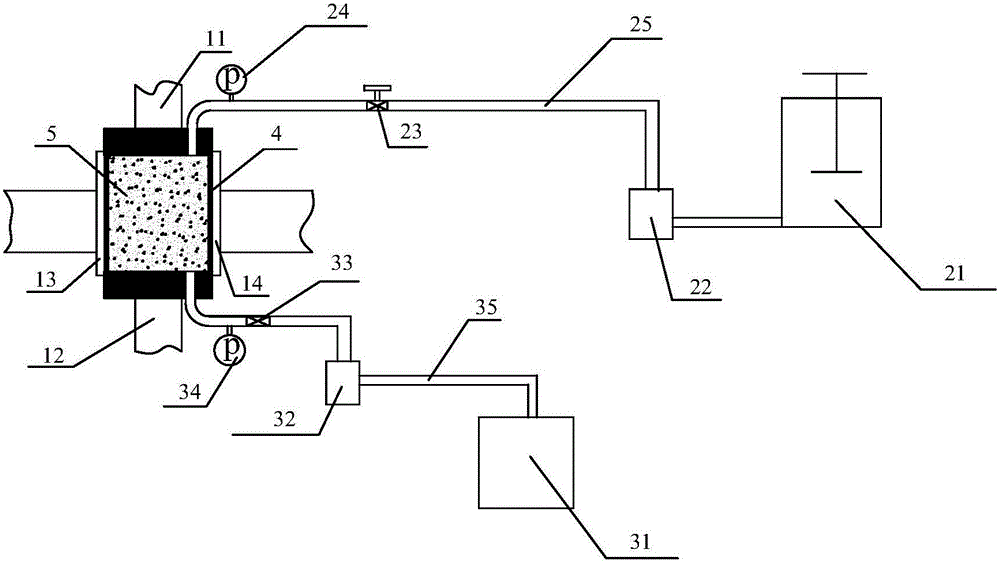

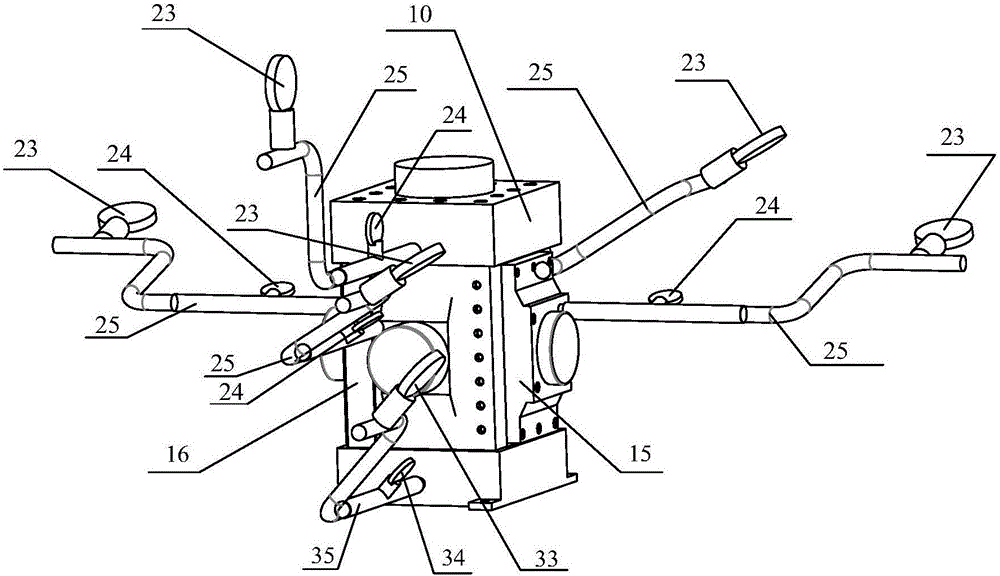

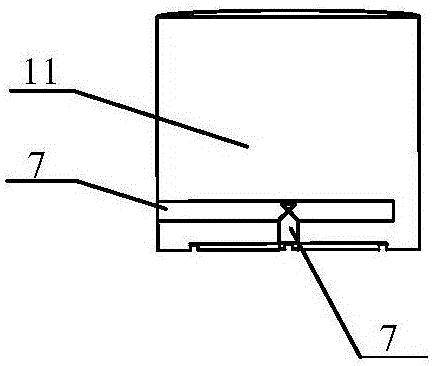

[0035] like Figure 1 to Figure 6 As shown, this embodiment provides a three-way stress-seepage coupled grouting test system, the loading unit includes an upper indenter 11, a lower indenter 12, a left indenter 13, a right indenter 14, a front indenter 15 and a rear indenter 16. The upper indenter 11, the lower indenter 12, the left indenter 13, the right indenter 14, the front indenter 15 and the rear indenter 16 are respectively movably connected to the upper, lower, left, right, front and rear of the support frame 10. position, the hydraulic unit is connected with the upper pressure head 11, the lower pressure head 12, the left pressure head 13, the right pressure head 14, the front pressure head 15 and the rear pressure head 16 through the hydraulic pipeline. The upper pressure head 11, the left pressure head 13, the right pressure head 14, the front pressure head 15 and the rear pressure head 16 are all provided with a grouting flow channel 7, the upper pressure head 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com