Testing device and testing method for uniaxial compressive strength of coal-rock mass

A technology for uniaxial compressive strength and testing equipment, which is applied in the direction of measuring equipment, strength characteristics, and the use of stable tension/pressure to test the strength of materials, etc., can solve the problems of drilling holes, fewer test points, and high cost, and achieve easy access, Feasibility improvement and strong pressurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

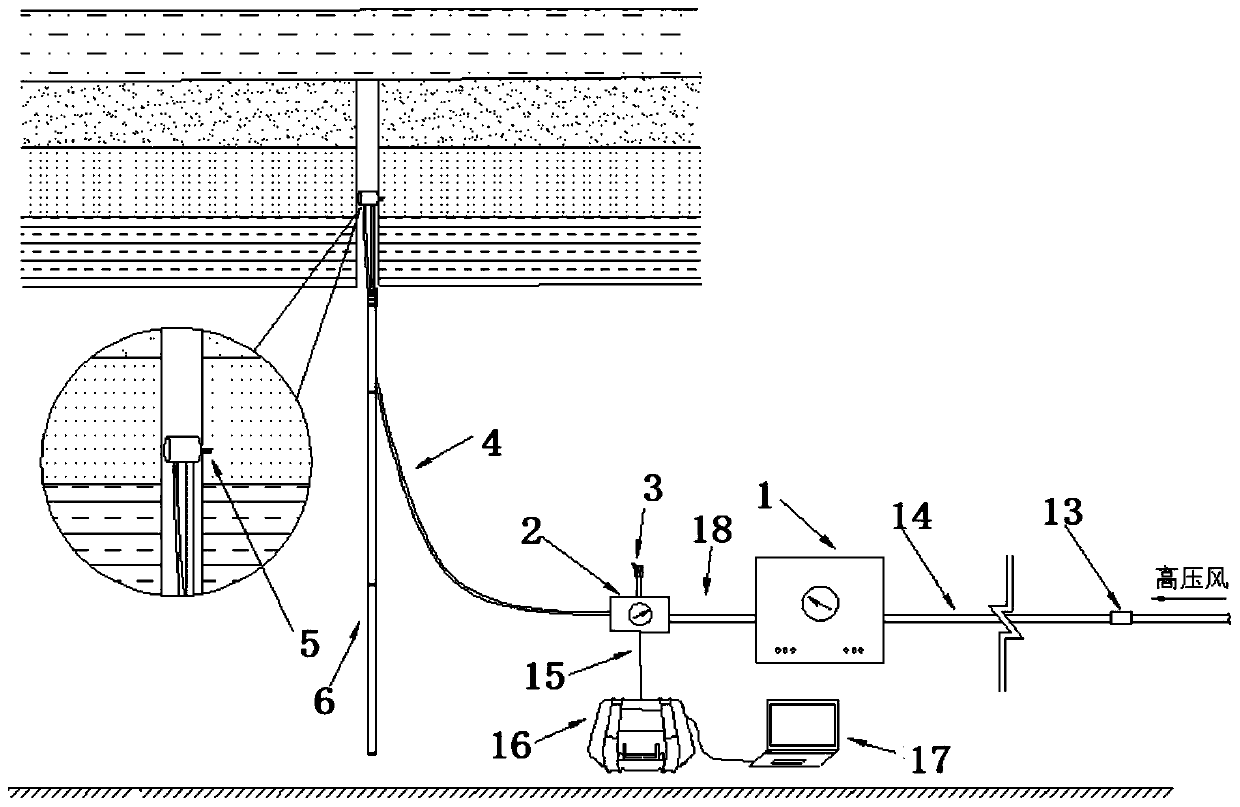

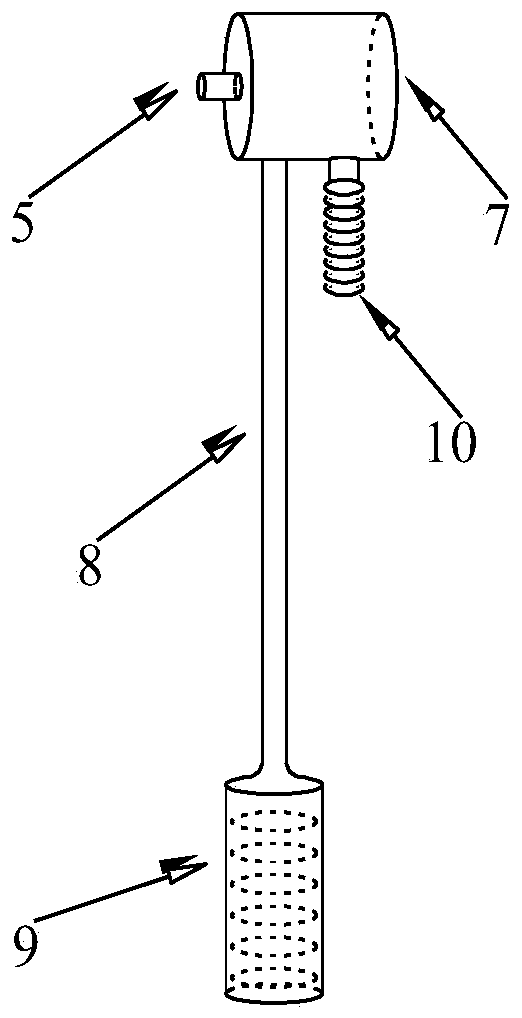

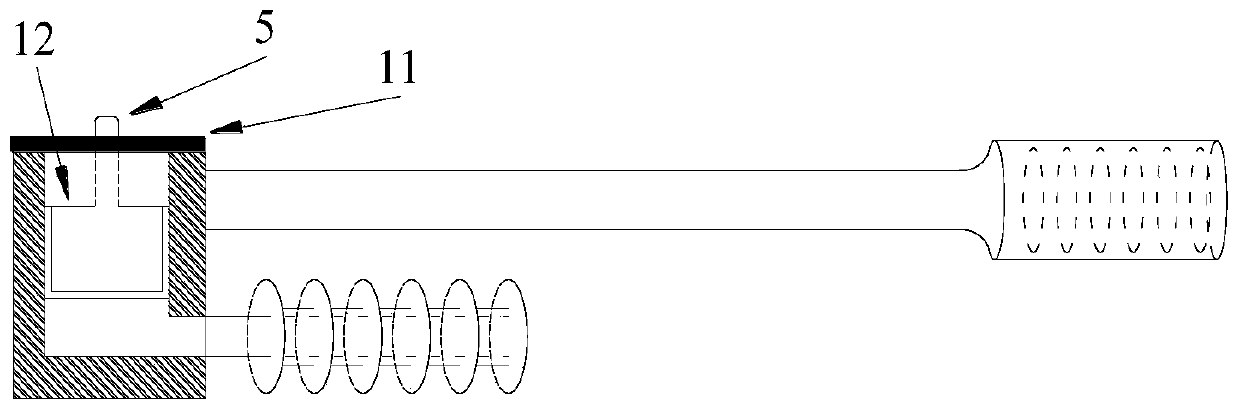

[0056] A specific embodiment of the device of the present invention, such as Figure 1-Figure 3 As shown, a coal and rock mass uniaxial compressive strength test device includes a power supply device, a probe 7 and a mounting rod 6; the power supply device is used to provide power for the probe 7, and the power supply device is connected to the probe 7 through a high-pressure pipe 4 The power supply device includes a pneumatic booster pump 1 and a three-way valve 2; the pneumatic booster pump 1 is connected to a high-pressure air source; the first end of the three-way valve 2 is connected to the pneumatic booster pump 1 through a pressure-resistant pipe 18, and the pressure-resistant pipe 18 can be a steel wire wound pressure-resistant rubber hose, the second end of the three-way valve 2 is connected to the probe 7 through the high-pressure pipe 4; the probe 7 is connected to the installation rod 6, and the installation rod 6 is used to send the probe 7 to the test section; the...

Embodiment 2

[0067] This embodiment provides a test method using the above-mentioned uniaxial compressive strength test device for coal and rock mass, using the uniaxial compressive strength test device for coal and rock mass provided in Example 1, the method includes the following steps:

[0068] S1. Select the test section of the coal or rock mass to be tested; the test section can be selected at different depths according to the test needs, and can test small apertures and weak coal and rock masses that cannot be sampled;

[0069] S2. Connect the power supply device: connect the pneumatic booster pump 1 with the high-pressure air source through the conversion joint 13 and the high-pressure air pipe 14 to provide a power source for it; the pneumatic booster pump 1 is connected to the three-way valve through the pressure-resistant pipe 18 2 connected to the first end; the third end of the three-way valve 2 is connected to the pressure relief pipe; the three-way valve 2 is connected to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com