Method for determining capacity of underground reservoir of mine

An underground reservoir and a technology for determining methods, applied in measuring devices, instruments, etc., can solve problems such as groundwater loss, restrict normal production in mining areas, and unbalanced water use, and achieve the effects of solving unbalanced water use, realizing reasonable protection, and solving water problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment, the invention is described in detail.

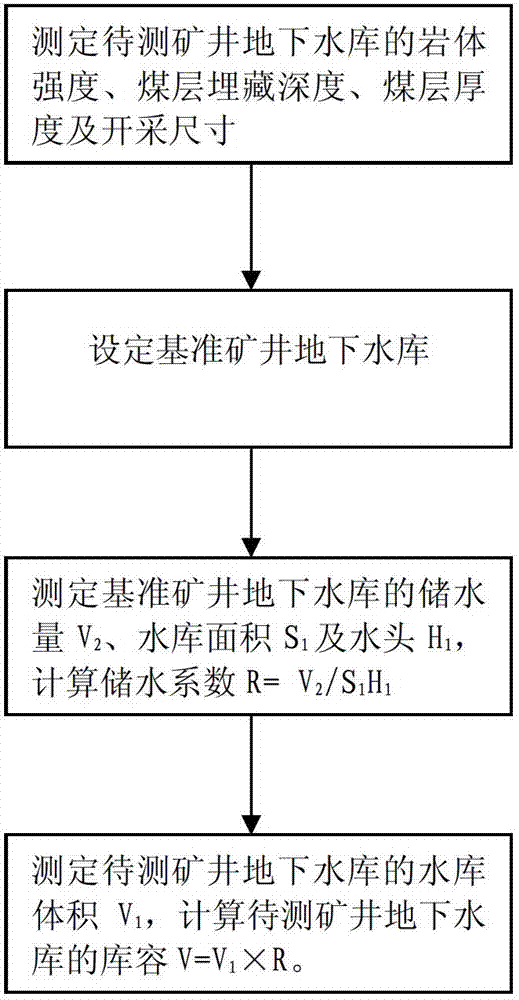

[0019] The method for determining the storage capacity of the mine underground reservoir provided by the invention comprises the following steps:

[0020] Step ①: Determine the rock mass strength, coal seam burial depth, coal seam thickness and mining size of the underground reservoir of the mine to be tested. For example, the rock mass strength (coal seam crushing strength) of the underground reservoir is 88, the coal seam burial depth is 95m, the coal seam thickness is 3.7m and the mining size is 200m×1500m.

[0021] Step ②: set the reference mine underground reservoir, the rock mass strength, coal seam burial depth, coal seam thickness and mining size of the reference mine underground reservoir are consistent with the mine underground reservoir to be measured, the present invention can preferably establish the reference mine underground reservoir model, Make the rock mass strength, coal se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com