Aquifer preventing and controlling method for coal face roof plate separation layer

A technology for coal mining face and roof separation layer, which is applied in drainage, mining equipment, earthwork drilling and mining, etc. It can solve the problems that affect the normal advancement of the working face, the water accumulation in the separation layer cannot be reached, and the water hazard accidents of the working face. , to achieve the effects of avoiding layer water damage accidents, easy implementation, safe and efficient mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

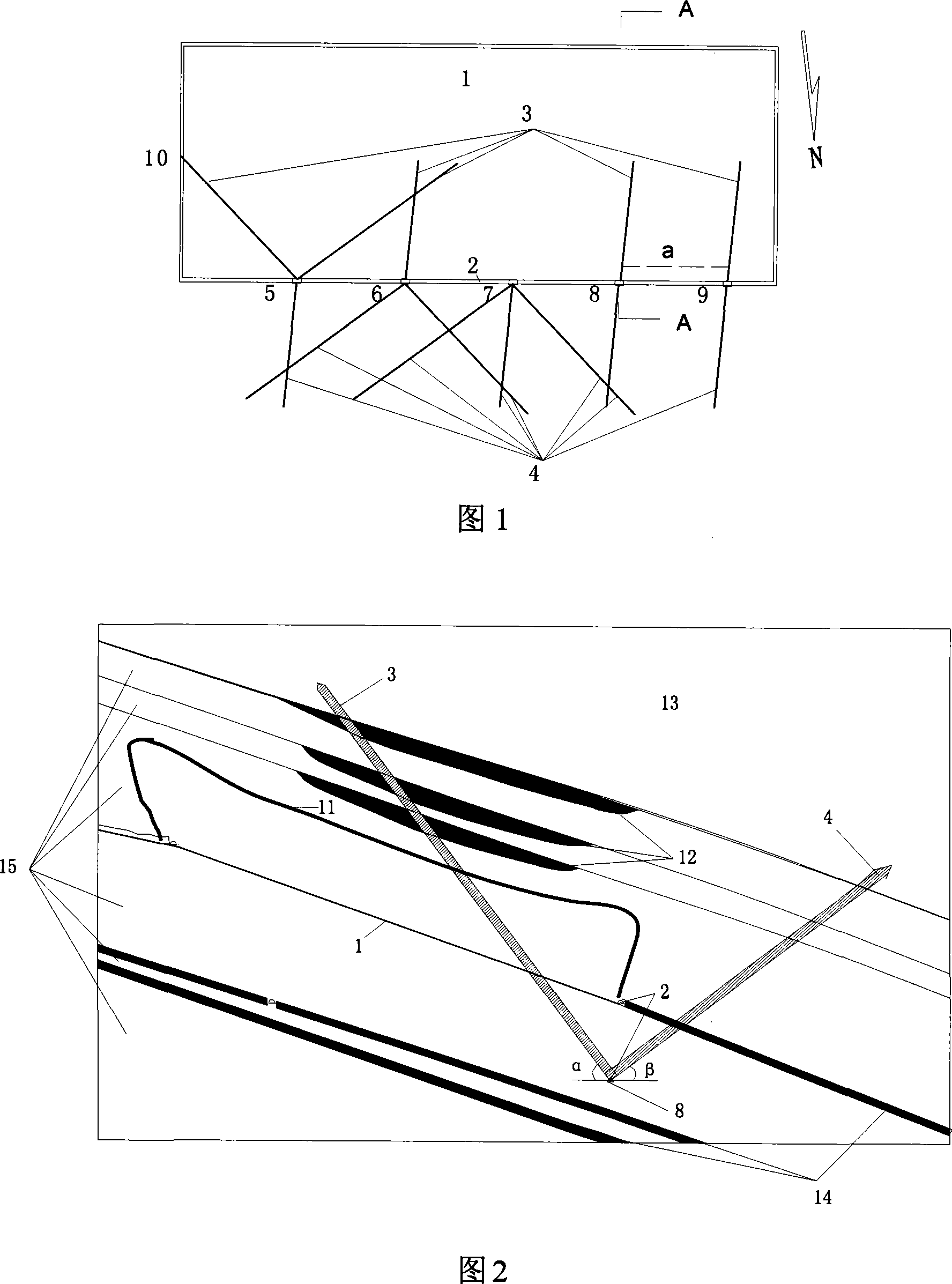

[0020] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

[0021] First of all, the construction of the upper drainage hole 3 (drilled in the working face in the uphill direction) and the lower drainage hole 4 (drilled outside the working face in the downhill direction) is carried out at intervals in the lower trough 2 (track lane, machine lane) of the coal mining face 1. Drainage hole group (downhole borehole) 5, 6, 8, 9 and drainage hole group 7 composed of lower drainage hole 4 are constructed sequentially. The size of the water volume is determined. If the water output is large, the number of drilling holes will be large. On the contrary, the number of drilling holes will be small. Generally, there are no more than 3 drainage holes in each group. The number of drilling holes in the downhill direction should be more than the number in the uphill direction. The azimuth angle of the hydrophobic hole group co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com