Comprehensive mechanized coal mining method of steeply inclined and extremely thick coal seam planing conveyor

A comprehensive mechanized, extra-thick coal seam technology, applied in special mining, surface mining, earthwork drilling and mining, etc., can solve the problems that cannot be adopted and independent negative pressure ventilation and layout, so as to improve unit yield and efficiency, solve Coal mining method issues, the effect of ensuring safe and efficient mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

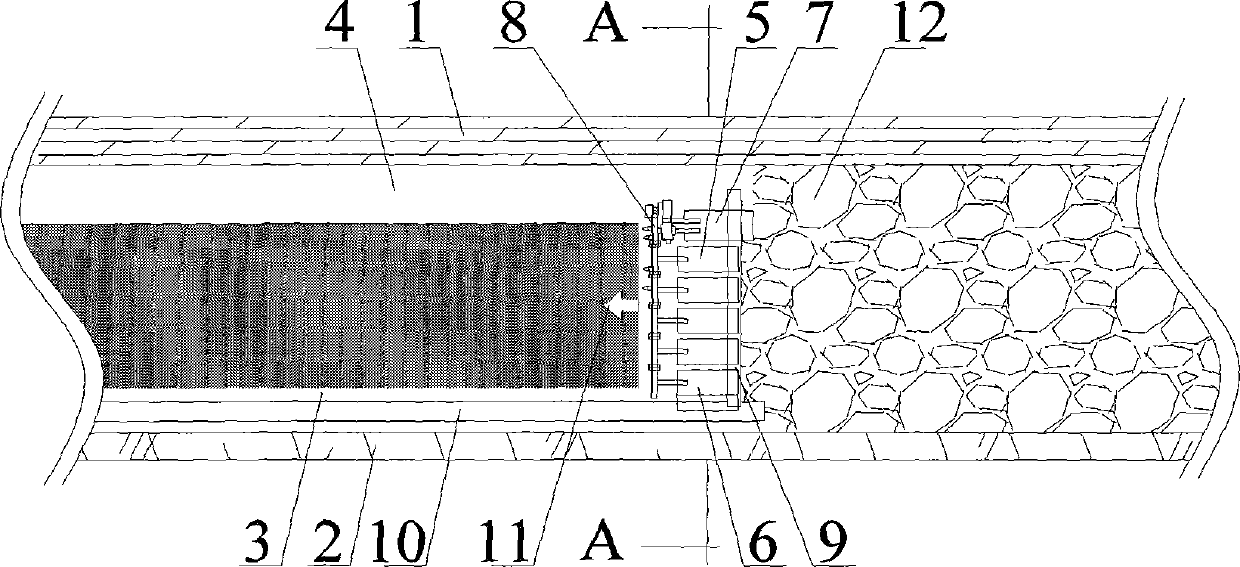

[0013] exist figure 1 In the plan view of , the top-coal caving hydraulic support (5) and the top-coal caving hydraulic support (6, 7) at both ends are arranged along the working face, and there is one top-coal caving hydraulic support (6, 7) at The quantity of support (5) is determined by the length of working face. The working face uses a planer to drop and transport coal, and the coal is loaded into the trough scraper conveyor (10). The cutting depth of one coal cutting cycle of the planer is 0.3m. After two cycles of cutting by the planer, Move the support once, and the moving step is 0.6m. After the support moves forward, the collapsed top coal is put into the iron chute (9) from the rear of the top coal caving hydraulic support (5, 6, 7) and transported out to the scraper conveyor (10) along the trough, where it is scraped along the trough. The slab conveyor (10) transports the coal out of the working face.

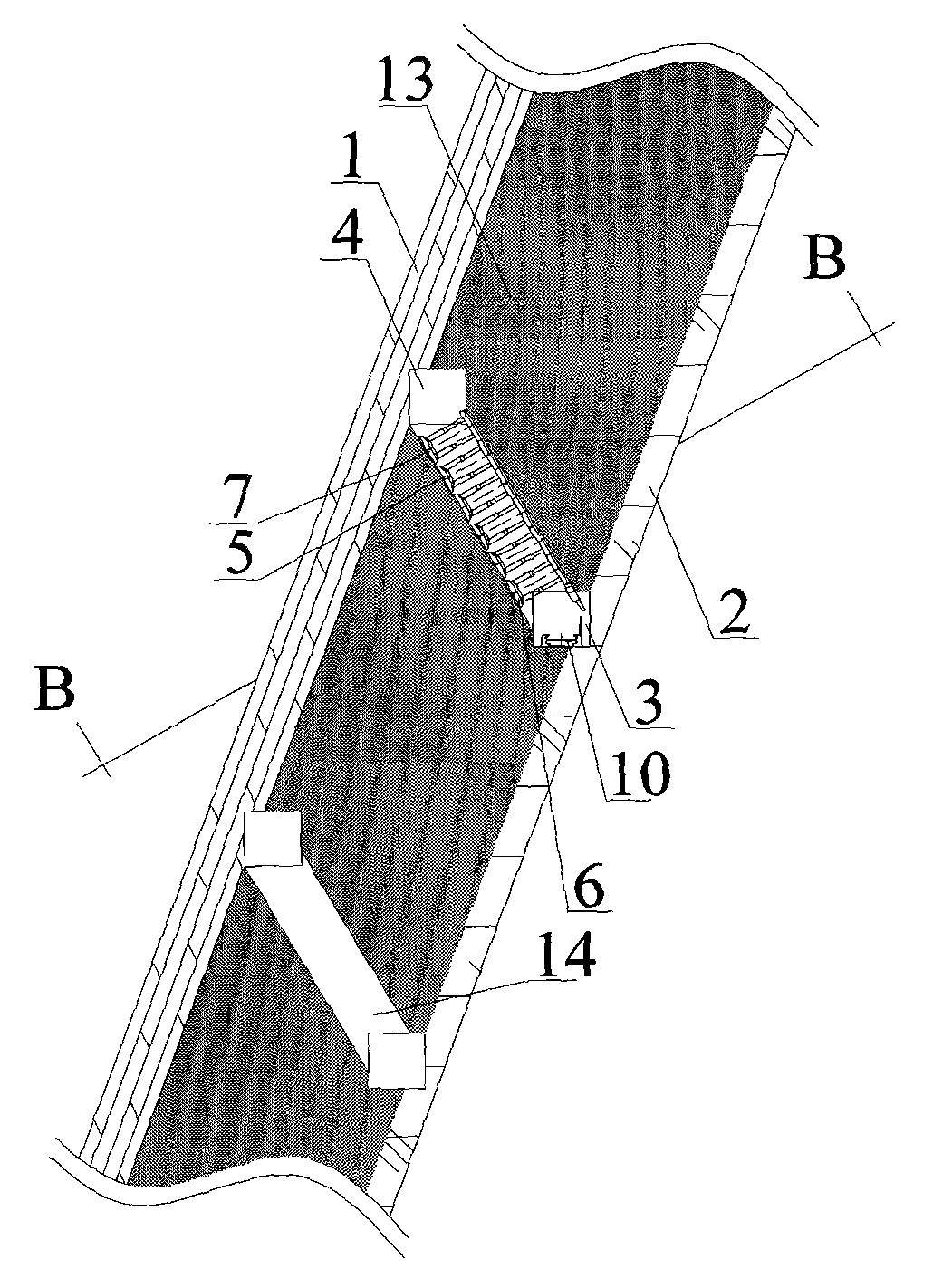

[0014] exist figure 2 In the shown embodiment, it can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com