Dimension and dip angle adjustable type coal mine stope similar model test system and method

A similar model and test system technology, applied in the field of similar model test system in coal mine stope with adjustable size and inclination angle, can solve the problems of inability to simulate, lack of universality, and test error amplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

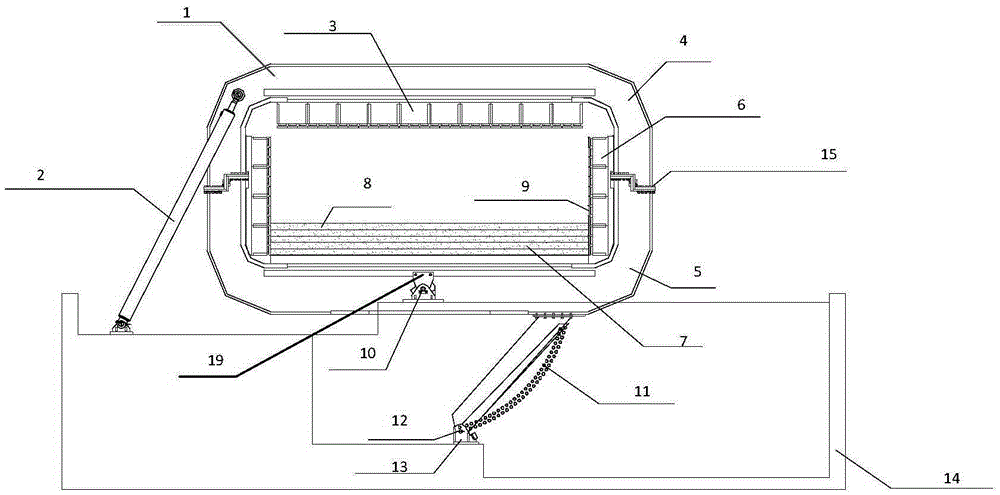

[0051] figure 1 It is a schematic structural view of the size and inclination adjustable type coal mine stope similar model test system in Embodiment 1 of the present invention, as figure 1 As shown, the size and inclination adjustable coal mine stope similar model test system provided by the present invention includes: model bearing frame 1, pressure loading device, model frame rotating device 2, centralized control device and monitoring device;

[0052] The model bearing frame is used to lay similar models in the stope; the centralized control device is used to send pressure control commands to the pressure loading device according to the pressure value set in the test and send rotation control commands to the model frame rotation device according to the inclination value set in the test; The pressure loading device is used to apply pressure to the model bearing frame according to the pressure control command; the model frame rotation device is used to rotate the model beari...

Embodiment 2

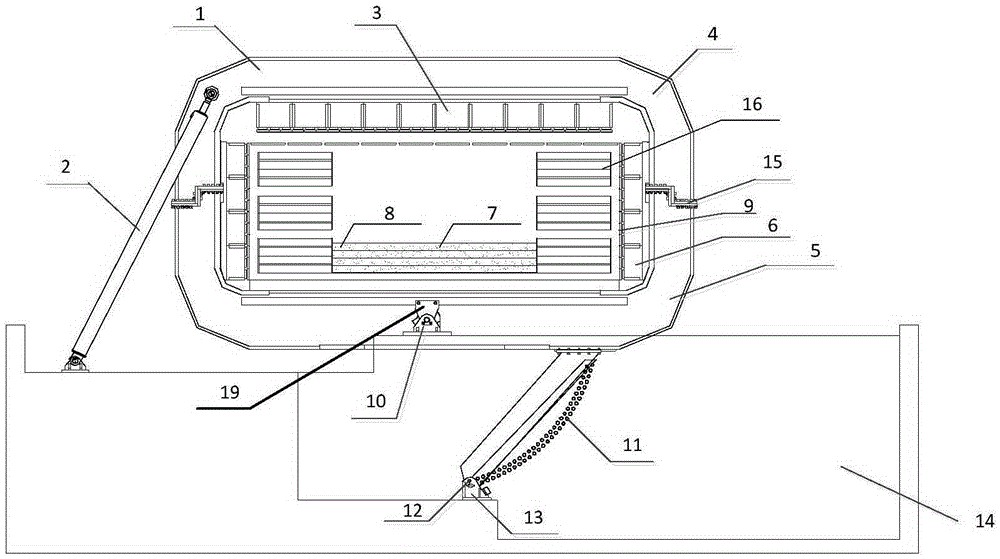

[0062] Embodiment 2 is basically the same as Embodiment 1, and its main difference is that if the length of the similar model in the stope in the experimental scheme is small, it is not enough for the accommodating width of the model bearing frame, such as figure 2 As shown, the left and right sides of the model carrying frame are respectively provided with force transmission pads 16, and the force transmission pads 16 are symmetrically distributed along the center line of the model carrying frame 1 to ensure that the laid model body is located in the center of the frame, so that Lay model bodies of different length specifications. The pressure loading device includes a lateral pressure loading device 6 and a top pressure loading device 3 ; the lateral pressure loading device 6 applies a horizontal gradient pressure to the model through a force transmission pad 16 . Since the force transmission pad 16 can be set in the model bearing frame 1, the size of the model bearing fram...

Embodiment 3

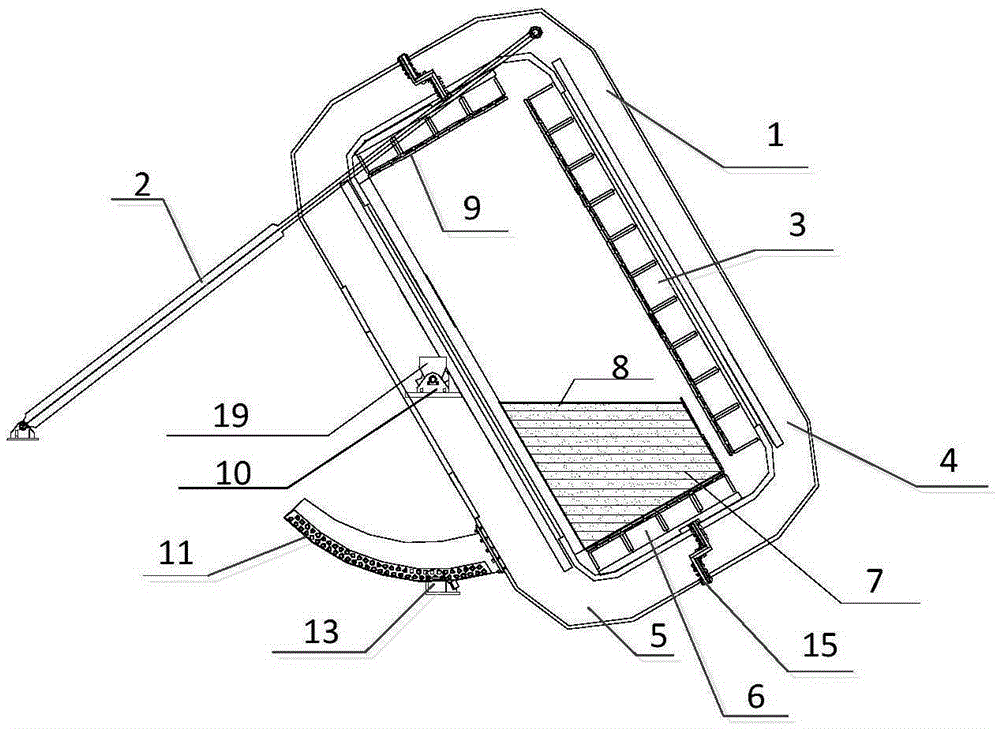

[0064] Embodiment 3 is basically the same as Embodiment 1, the main difference is that Embodiment 3 uses the test system in Embodiment 1 to carry out tests on formations with a certain dip angle, while Embodiment 1 is a test on formations with a model dip angle of zero ,Such as image 3 As shown, it is the working state of the test system of the present invention when simulating the inclined formation. In order to simulate the inclined formation, the model frame rotating device 2 drives the model carrying frame 1 to rotate a certain angle, and the rotation limit pin 12 leaves the rotation limit base 13, The rotation limit pin 12 is inserted into the small hole on the rotation limit plate 11 to keep the test system stable, and then a similar model of the stope is laid in the model carrying frame 1, and after the laying is completed, the model carrying frame 1 is turned back to Horizontal position, others are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com