Method for extracting gas close to lower coal layer through directional drilling in thin coal seam fully-mechanized coal mining gob-side entry

A coal seam gas and directional drilling technology, applied in gas discharge, ground mining, mining equipment, etc., can solve the problems of complex process and high cost, achieve the effect of increasing gas area, reducing gas content, and facilitating safe and efficient mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

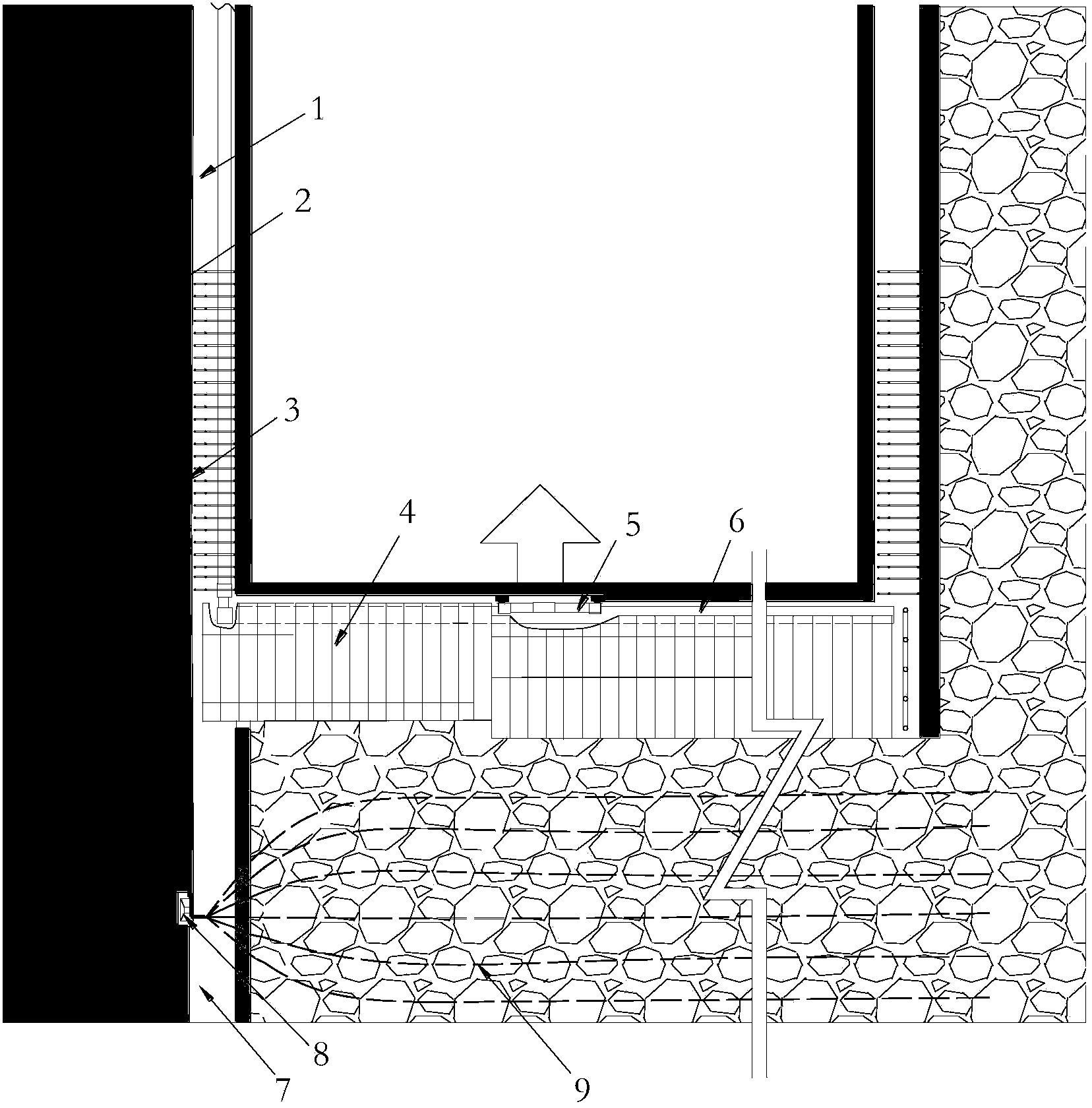

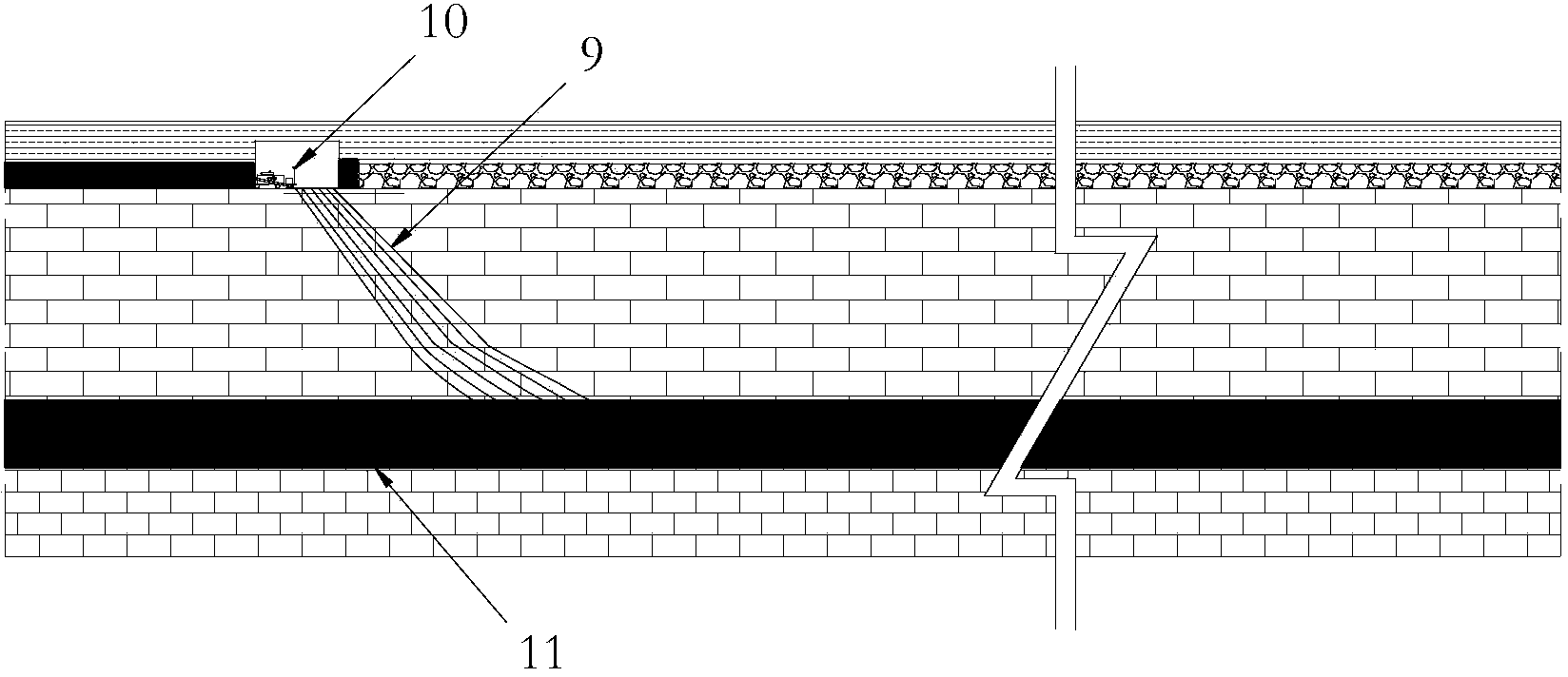

[0016] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0017] According to the present invention, the method for extracting gas from adjacent coal seams by directional drilling in gobside entry retention in fully mechanized thin coal seams, the specific steps are as follows:

[0018] a. During the mining process of the thin coal seam working face, the transportation level entry 1 of the working face of the coal seam is used as the return air entry level of the working face 2 of the lower section through the way of retaining the entry along the gob;

[0019] b. With the continuous mining of the thin coal seam working face under the synergy of the three processes of drum shearer 5 cutting coal, scraper conveyor 6 coal transportation, and hydraulic support 4 supporting the roof, the distance behind the thin coal seam working face shall not be less than A drilling field 8 is arranged in the 20m gobside entry 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com