Method for determining setting size of coal columns in fully mechanized caving coal mine gob-side entrydriving

A method and technology for determining coal pillars, which are applied in the field of determining the size of coal pillars in fully mechanized caving and gob-side tunneling, can solve the lack of scientificity, practicability and systematic understanding of the stability control and evaluation of coal pillar retention methods. and other problems, to achieve the effect of reducing the amount of maintenance works, reducing maintenance costs, and safe and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

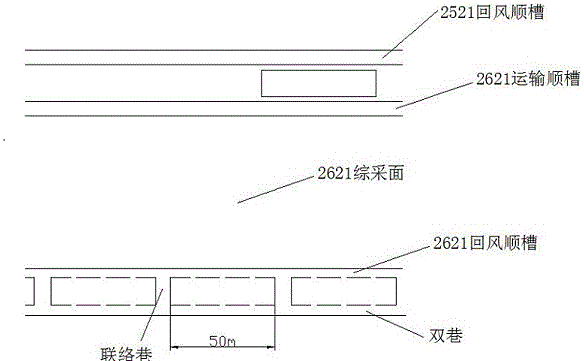

[0045] 1 Project overview

[0046] In a coal mine with a buried depth of 300m, the east and west of the 2621 working face are surface coal mining subsidence areas, and the east is the mined 2521 working face; the west is the goaf of the original South 1 working face 1421 and 1422, and the South 3 working face 6121 goaf , above the northern section are the gobs of 1511, 1611, and 1711 working faces, and the 2621 working face has become an island-type mining area. The 2621 working face is in the underground position as attached figure 1 And attached figure 2 shown. The histogram of coal seam engineering geology of the working face is attached image 3 shown.

[0047] The working face of the mining roadway is a rectangular section, the size is width × height = 4.7m × 3.5m, and the combined support design of hollow grouting anchor cable + anchor mesh spraying is adopted. The support parameters are: the anchor rod is φ 20mm threaded steel anchor rod, the length of the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com