Stereo treatment method for low-occurrence and high-emission gas according to sources and zones

A technology of gas and storage, which is applied in the field of low-occupancy and high-emission gas separation and three-dimensional management, and can solve the problems of difficult pre-pumping, high gas emission management, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

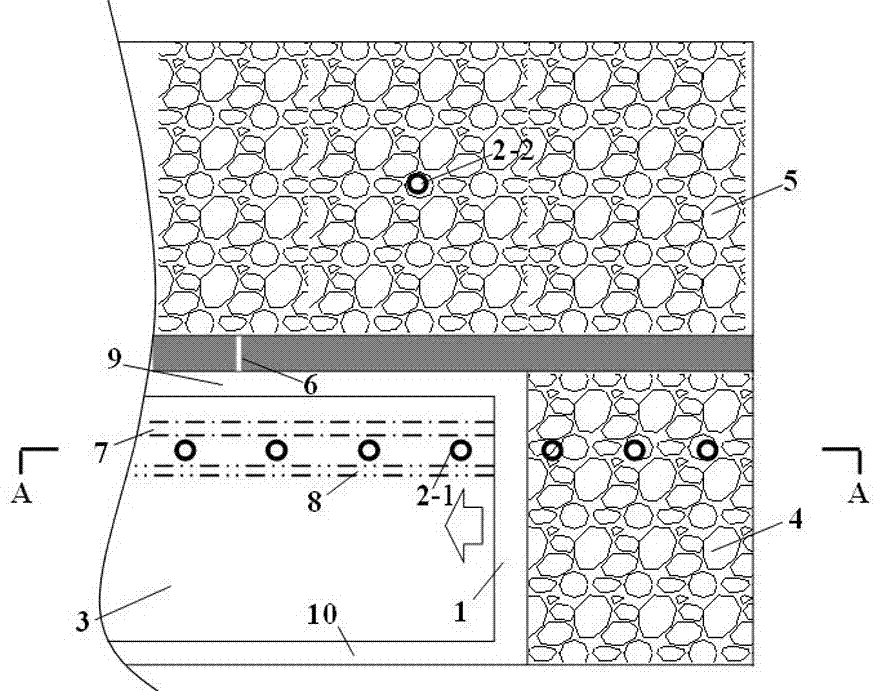

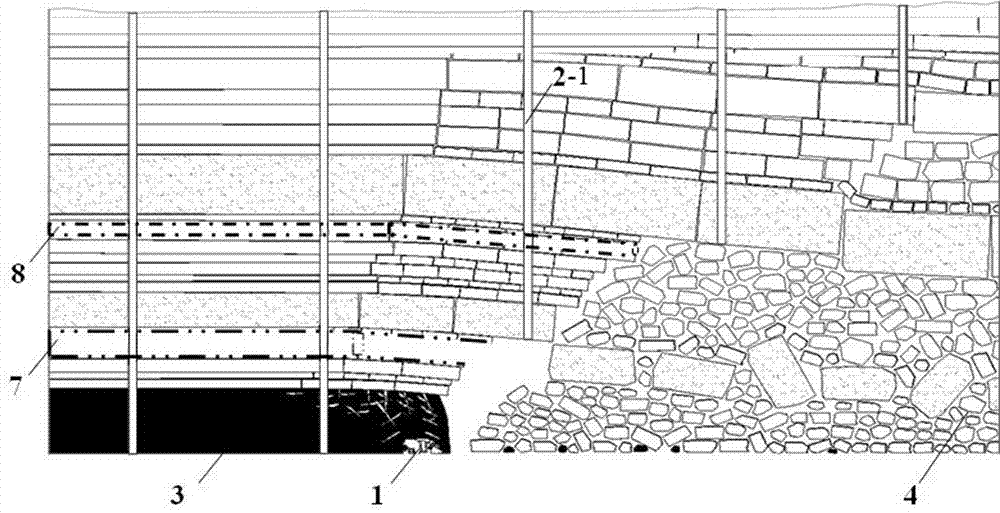

[0017] Taking the gas extraction of extra-thick coal seam mining in Datong mining area as an example below, the present invention will be further described in conjunction with the accompanying drawings:

[0018] Firstly, at the mining front of this working face 1, a row of continuous first gas drainage boreholes 2-1 are arranged at an interval of 50m vertically downward from the surface in the advancing direction of this working face 1 to the bottom of the coal seam 3 of this working face. The length of this working face 1 is 200m , the thickness of the coal seam 3 in this working face is 20m, the distance between the first gas drainage borehole 2-1 and the return airway 9 is 50m, and according to the advance position of the working face 1, at least three first gas drainage boreholes 2-1 Working at the same time, for the fractured area of the advanced coal and rock mass of this working face 1, this working face 1 and the goaf 4 of this working face, which are close to the are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com