Mixed organic solvent-thermal method for preparing spherical or hollow spherical BiVO4

An organic solvent, hollow spherical technology, applied in inorganic chemistry, vanadium compounds, chemical instruments and methods, etc., to achieve the effects of excellent application prospects, easy availability of raw materials, and controllable crystal phase structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

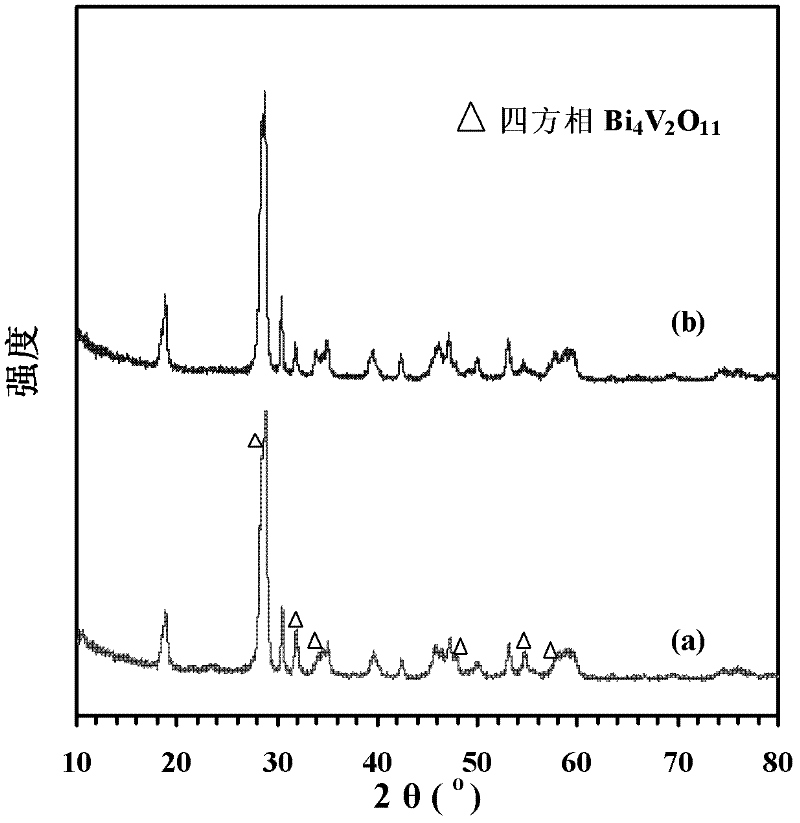

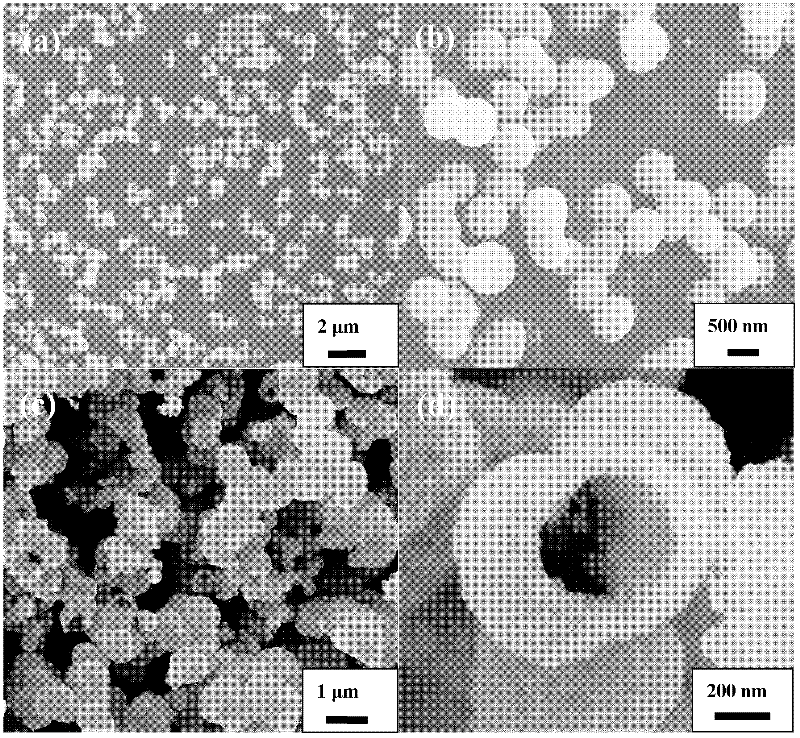

Embodiment 1

[0016] Example 1: Under stirring conditions, to ethanol / acetylacetone / concentrated HNO with a volume ratio of 9:1:1 3 (Concentration is 67wt%) in the mixed liquor (total volume is 55mL), add Bi(NO 3 ) 3 ·5H 2 O and NH 4 VO 3 3mmol each, continue to stir until the metal salt is completely dissolved, add 46.5mmol oleylamine, after mixing evenly, adjust the pH of the solution to 1.5 with triethanolamine, transfer the above mixed solution to a 100mL stainless steel self-pressurized tank lined with polytetrafluoroethylene still (volume filling degree is 80%), and placed in a constant temperature box at 100 ℃ constant temperature organic solvent heat treatment for 12h, after taking it out, let it cool to room temperature naturally, filter the product obtained, wash with deionized water 3 times and Washed with absolute ethanol for 3 times, dried at 60 °C for 12 h, placed in a muffle furnace, raised to 400 °C at a rate of 1 °C / min, and roasted for 4 h to remove the template to obt...

Embodiment 2

[0017] Example 2: Under stirring conditions, to ethanol / acetylacetone / concentrated HNO with a volume ratio of 9:1:1 3 (Concentration is 67wt%) in the mixed liquor (total volume is 55mL), add Bi(NO 3 ) 3 ·5H 2 O and NH 4 VO 33mmol each, continue to stir until the metal salt is completely dissolved, add 46.5mmol oleylamine, after mixing evenly, adjust the pH of the solution to 5 with triethanolamine, transfer the above mixed solution to a 100mL stainless steel self-pressurized tank lined with polytetrafluoroethylene still (volume filling degree is 80%), and placed in a constant temperature box at 100 ℃ constant temperature organic solvent heat treatment for 12h, after taking it out, let it cool down to room temperature naturally, filter the product obtained, wash with deionized water 3 times and Washed with absolute ethanol for 3 times, dried at 60 °C for 12 h, placed in a muffle furnace, raised to 400 °C at a rate of 1 °C / min, and roasted for 4 h to remove the template to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com