Framework type asphalt mixture gradation design method

A technology of asphalt mixture and design method, which is applied in the field of gradation design of asphalt mixture, can solve the problems of cumbersome design process, lack of skeleton judgment, etc., and achieve the effect of good high temperature stability and strong anti-rutting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

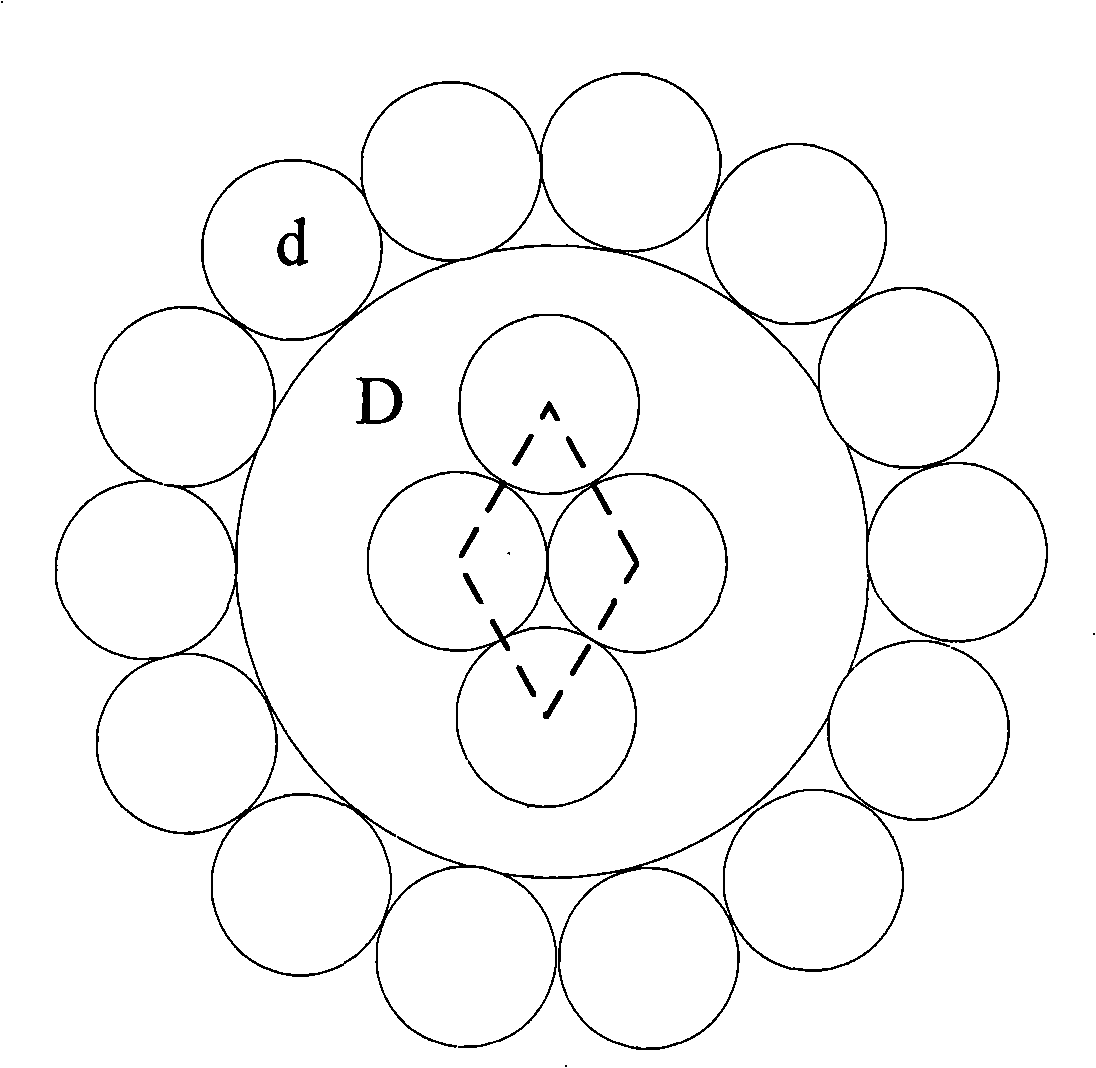

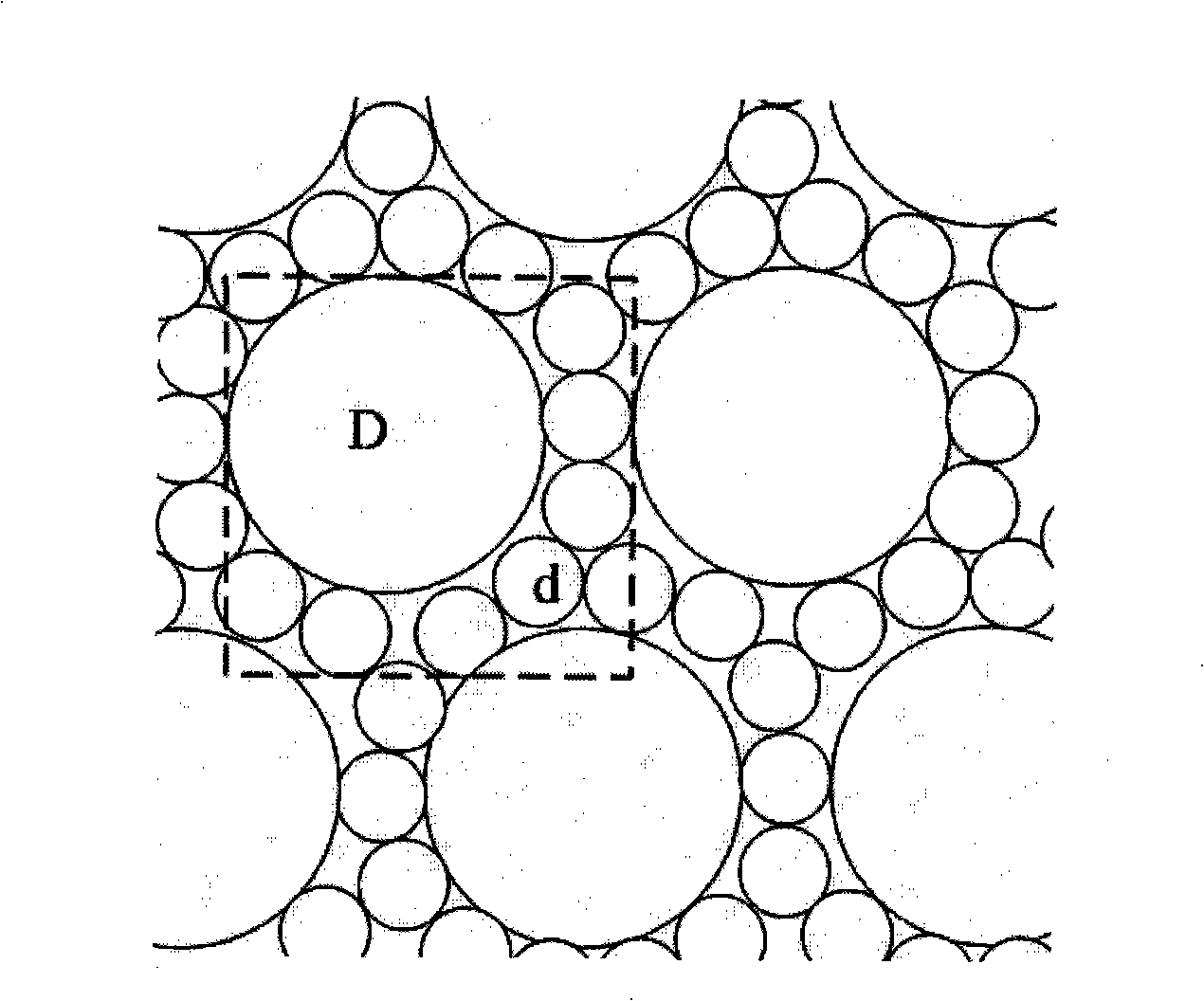

[0021] 1. Skeleton support model of asphalt mixture

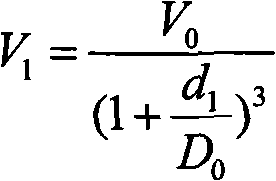

[0022] When particles of different particle sizes are mixed, the contact state between particles can be adopted as figure 1 The three-dimensional model shown is described. Assuming that the shape of the mineral material particle is a sphere, when the coarse particle with the particle size D is wrapped by the fine particle with the particle size d, the number of contact points between the coarse particle and the fine particle depends on the The number of fine particles that can be arranged on the surface. The fine particles distributed on the surface of the coarse aggregate contact each other and cover the surface of the coarse aggregate; connect the centers of the three contacting fine particle spheres to form an equilateral triangle, and the side length of the triangle is approximately equal to the particle diameter d of the fine particles . It can be seen that the spherical surface of a virtual sphere whose diameter is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com