Method for esterification reaction of konjac glucomannan

A technology of konjac glucomannan and glucomannan ester, which is applied in the field of mechanochemistry and achieves the effects of short time consumption, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 50 grams of konjac glucomannan is carried out esterification:

[0021] Step 1: Dry konjac glucomannan at 60°C with a blower until the water content is 3%, weigh 50 g, and add 0.5 g of sodium hexametaphosphate as an esterification modifier;

[0022] The second step: Prepare the grinding medium according to the volume filling rate of 80% of the grinding tank of the vibratory mill. Alloy balls with diameters of 15 mm, 8 mm and 6 mm are used as the grinding medium, and the volume ratio of the three balls is 28:42: 30;

[0023] Step 3: Mix the above-mentioned konjac glucomannan and the grinding medium evenly, then add it into the above-mentioned grinding tank, seal the grinding tank, and start the vibrating mill to grind for 20 minutes;

[0024] Step 4: Separating the grinding medium from the sample by sieving to obtain the esterified konjac glucomannan.

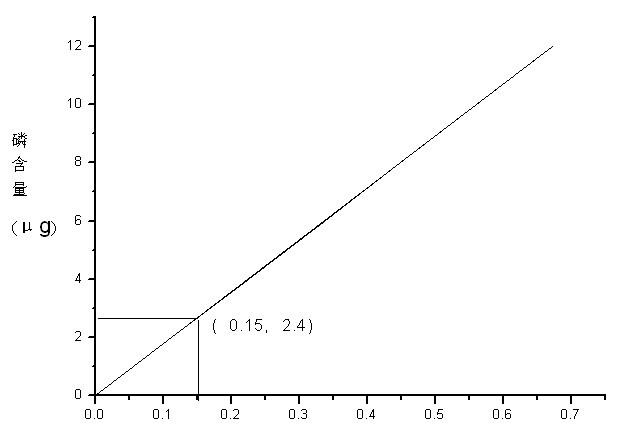

[0025] The digestion-spectrophotometer data picture of gained konjac glucomannan sample figure 1 As shown, the optica...

Embodiment 2

[0028] 50 grams of konjac glucomannan is carried out esterification:

[0029] Step 1: Dry konjac glucomannan in a vacuum oven at 80°C until the water content is 2%, weigh 50 g of dried konjac glucomannan, and add 2.5 grams of sodium trimetaphosphate as a modifier;

[0030] The second step: Prepare the grinding medium according to the volume filling rate of 85% of the grinding jar of the vibrating mill, using zirconia balls with diameters of 15 mm and 8 mm respectively as the grinding medium, and the volume ratio of the two kinds of zirconia balls is 2:1;

[0031] Step 3: Mix the above-mentioned konjac glucomannan and the grinding medium evenly, then add it into the above-mentioned grinding tank, seal the grinding tank, and start the vibrating mill to grind for 30 minutes;

[0032] Step 4: Separating the grinding medium from the sample by sieving to obtain the konjac glucomannan of the esterification reaction.

[0033] Table 1 is the X-ray fluorescence spectrum test data of th...

Embodiment 3

[0038] 50 grams of konjac glucomannan is carried out esterification:

[0039] Step 1: Dry konjac glucomannan at 70°C with a blower dryer until the water content is 3%, weigh 50g of dried konjac glucomannan, add 0.25g of sodium pyrophosphate as a modification agent;

[0040] Step 2: Prepare the grinding medium according to the volume filling rate of 90% of the grinding tank of the vibrating mill, using alumina balls with diameters of 8 mm and 6 mm respectively as the grinding medium, and the volume ratio of the two kinds of alumina balls is 1:1;

[0041] Step 3: Mix the above-mentioned konjac glucomannan and the grinding medium evenly and add it into the above-mentioned grinding tank, seal the grinding tank, and start the vibrating mill to grind for 60 minutes;

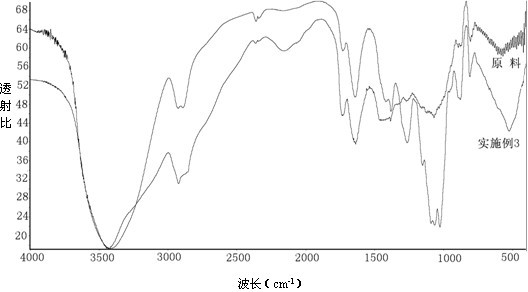

[0042] Step 4: Separating the grinding medium from the sample by sieving to obtain the konjac glucomannan of the esterification reaction. The infrared spectrum test results of the samples are as follows: figure 2 s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com