Patents

Literature

41 results about "Polycarbonate urethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

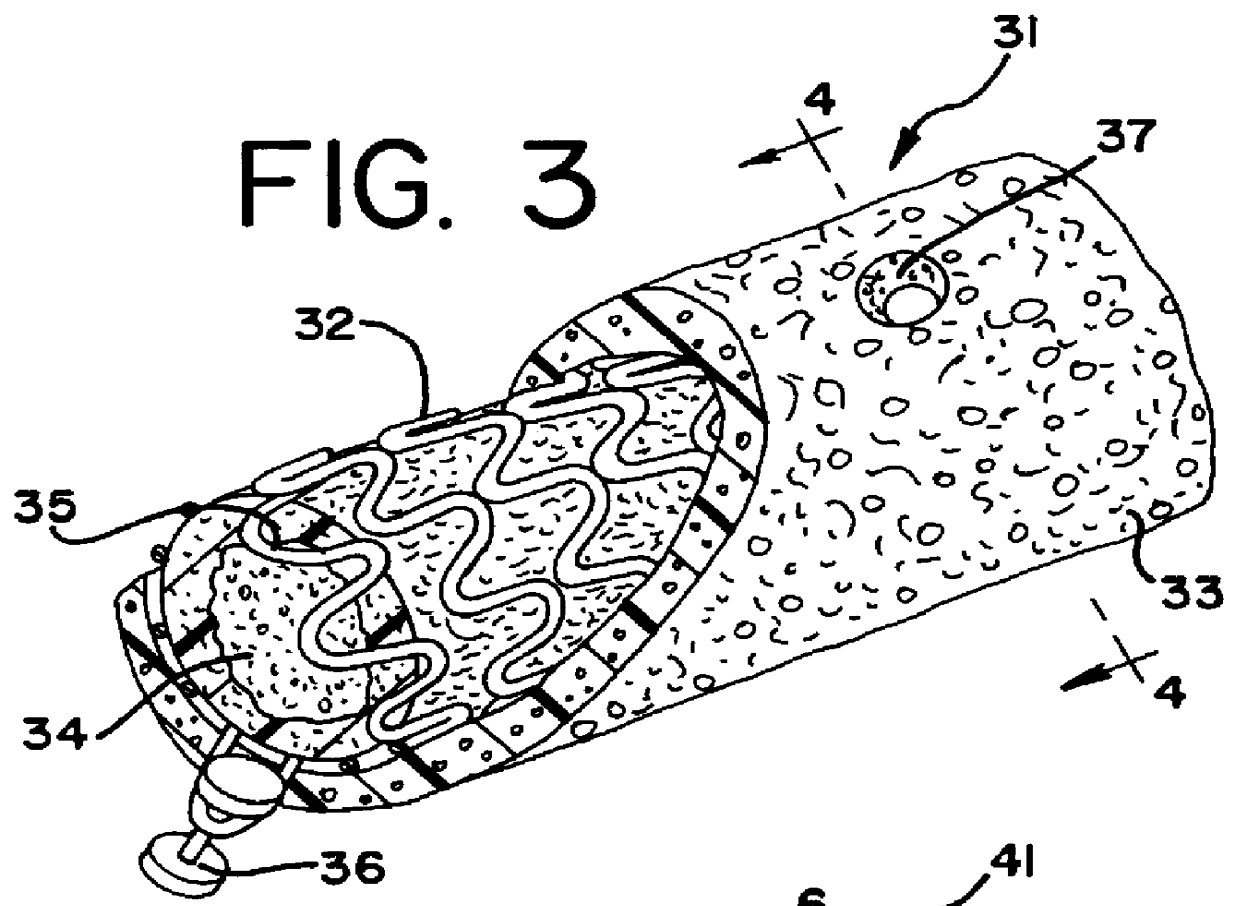

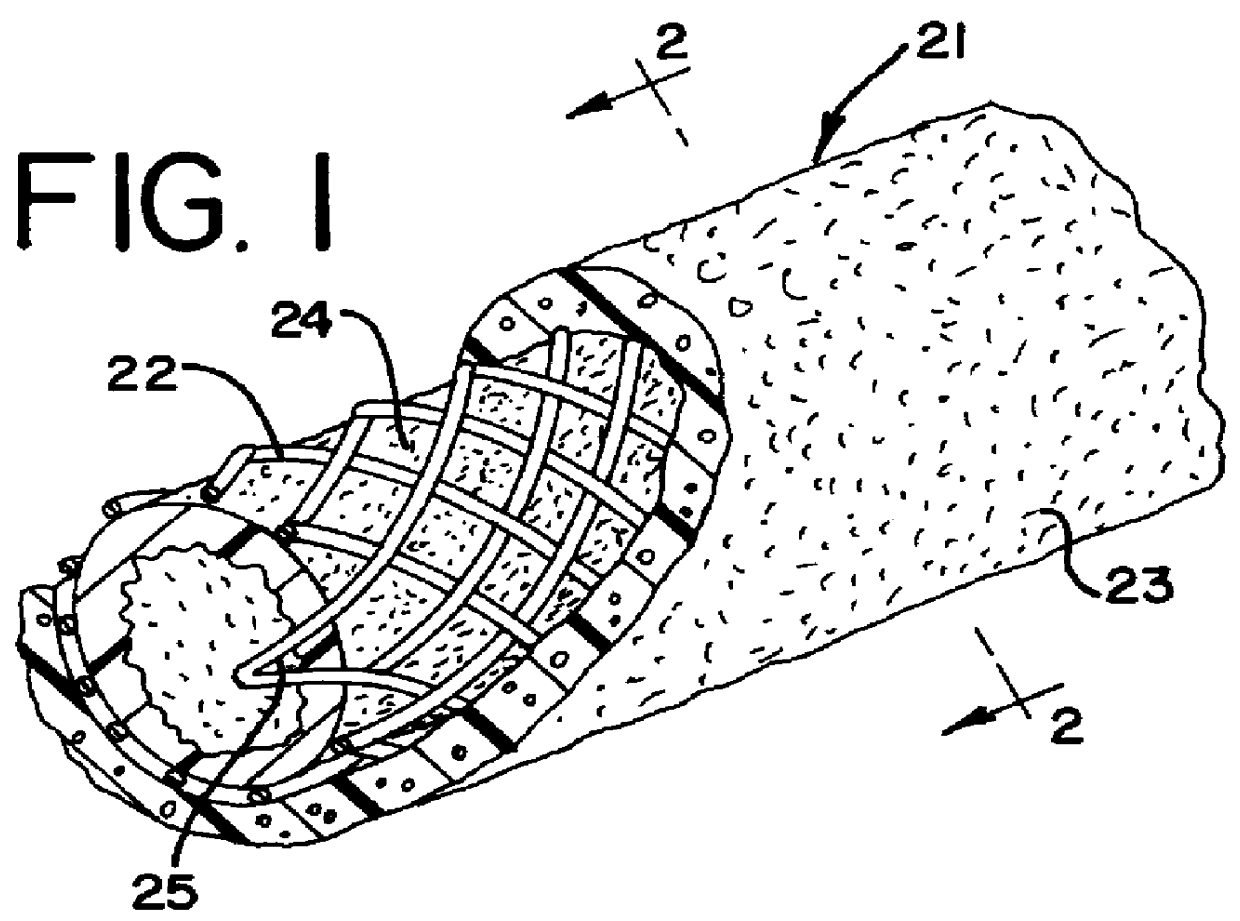

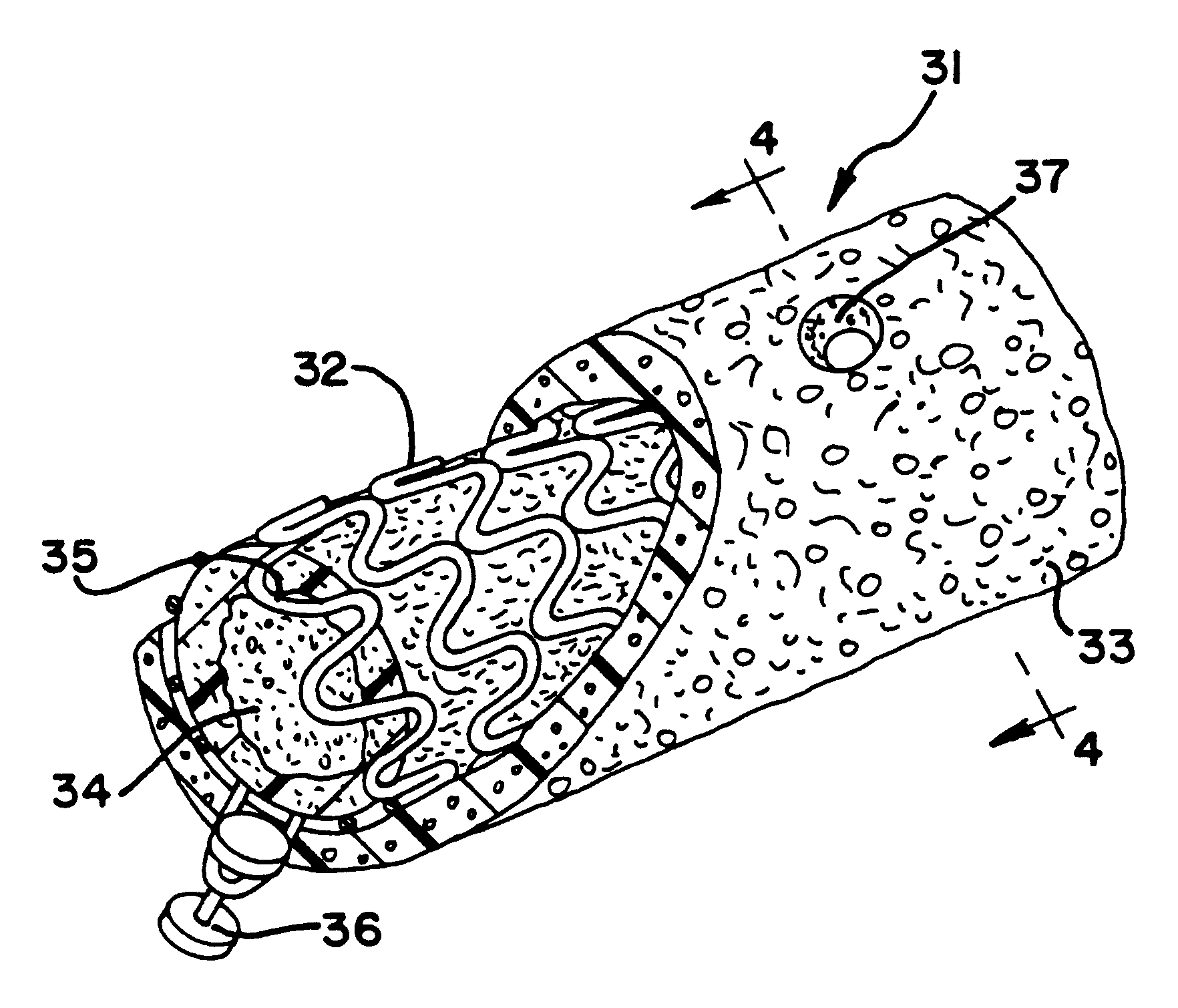

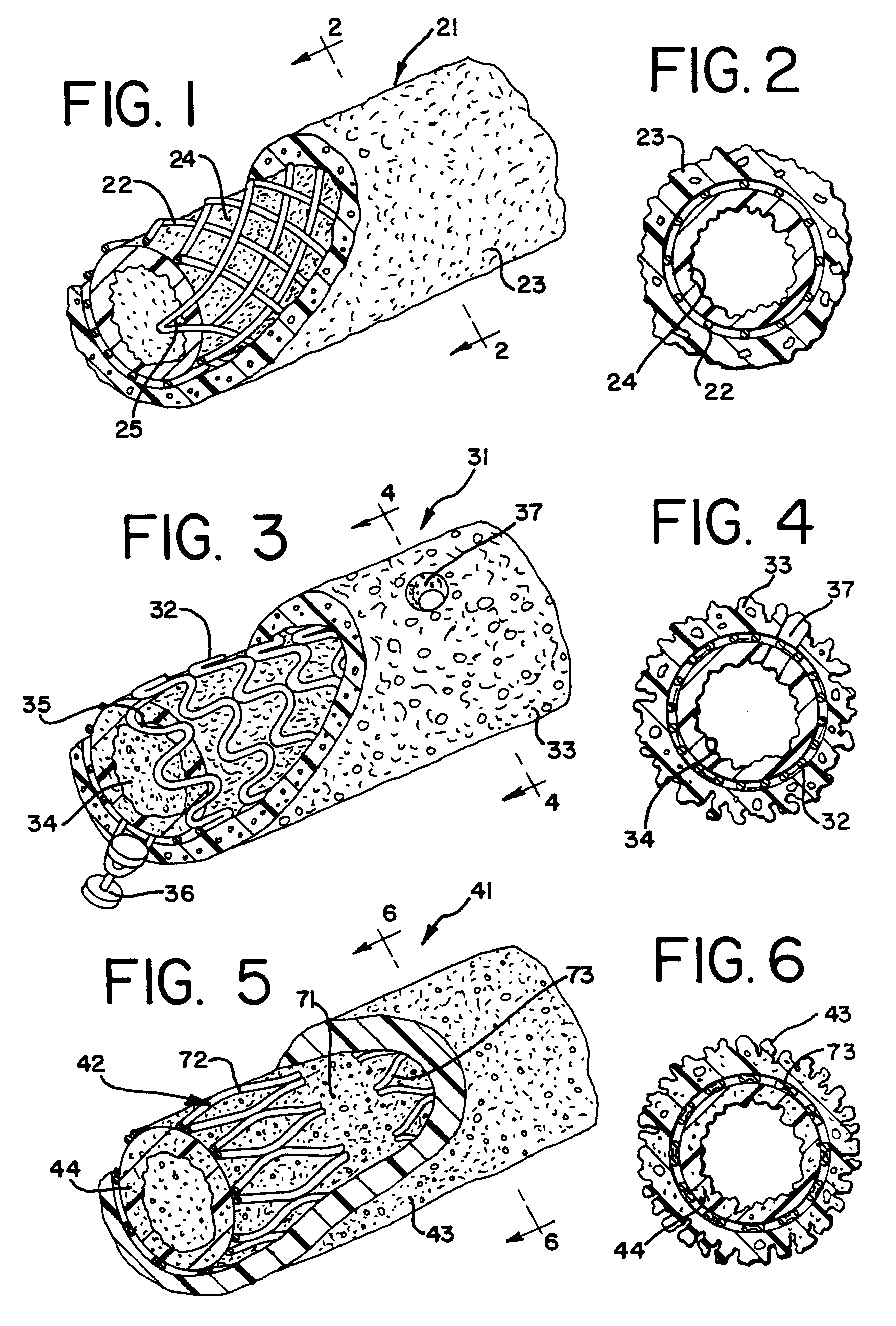

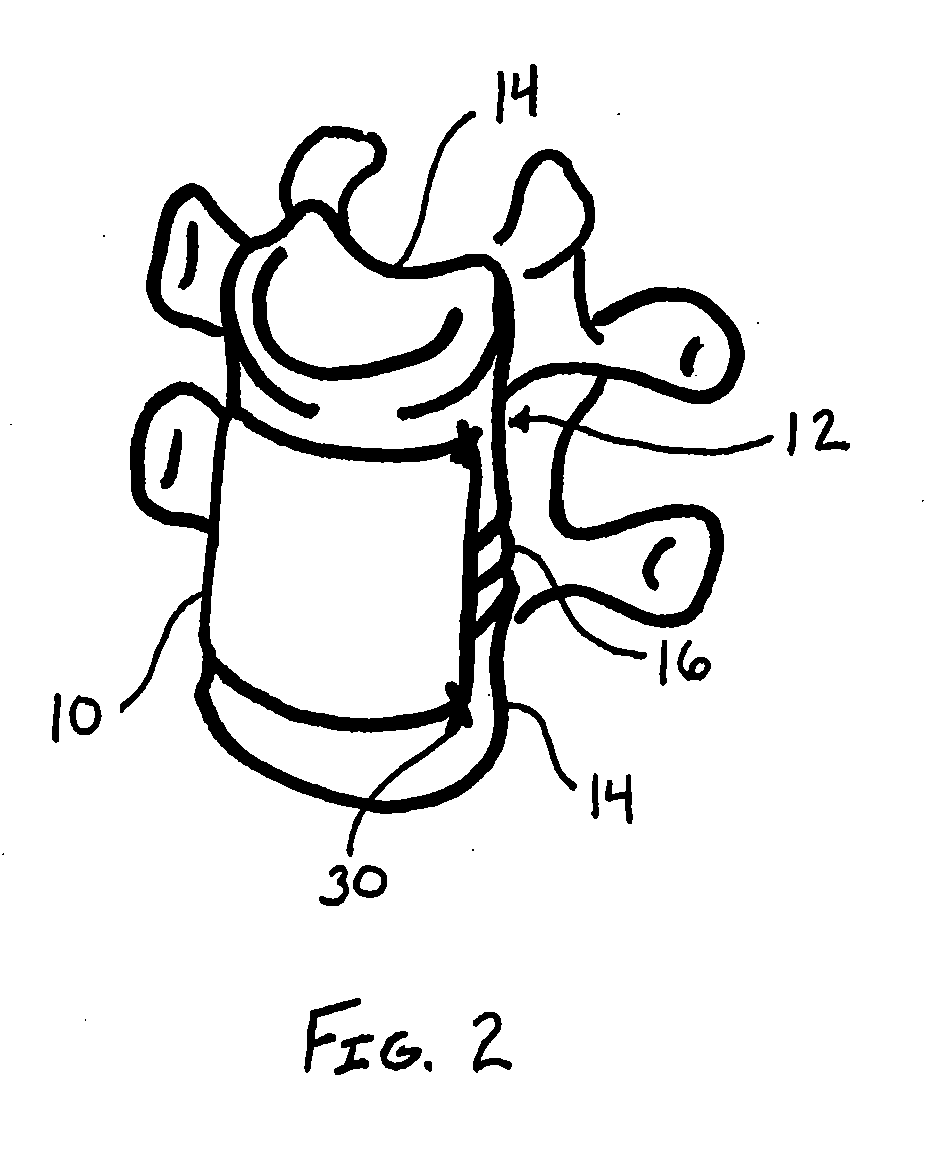

Expandable supportive endoluminal grafts

An endoluminal graft which is both expandable and supportive is provided either in a longitudinal form or in a bifurcated form. The graft expands between a first diameter and a second, larger diameter. The support component is an expandable stent endoprosthesis. A cover, liner, or a liner, or both a cover and a liner are applied to the endoprosthesis in the form of a stretchable wall material that is porous, elastomeric and biocompatible in order to allow normal cellular invasion upon implantation, without stenosis, when the expandable and supportive graft is at its second diameter. Preferably, the elastomeric wall material is a polycarbonate urethane.

Owner:LIFEPORT SCI

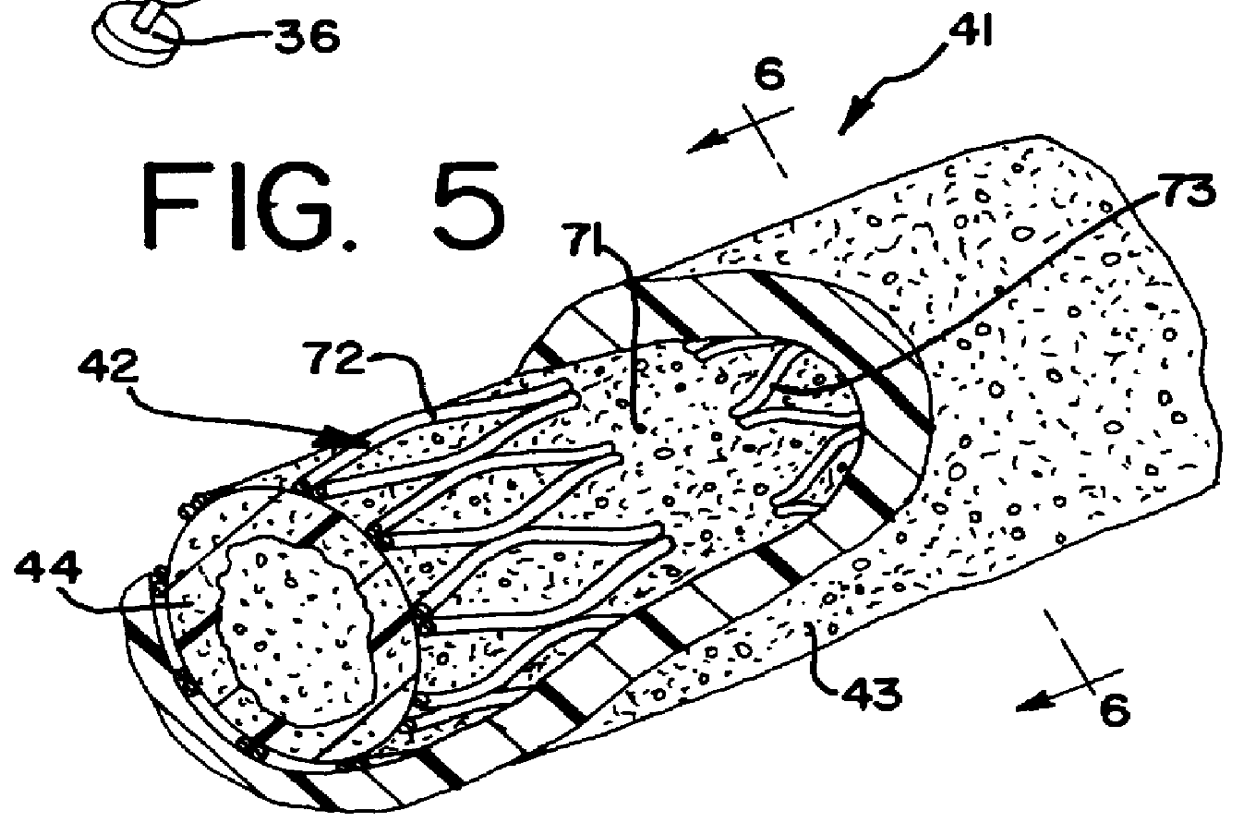

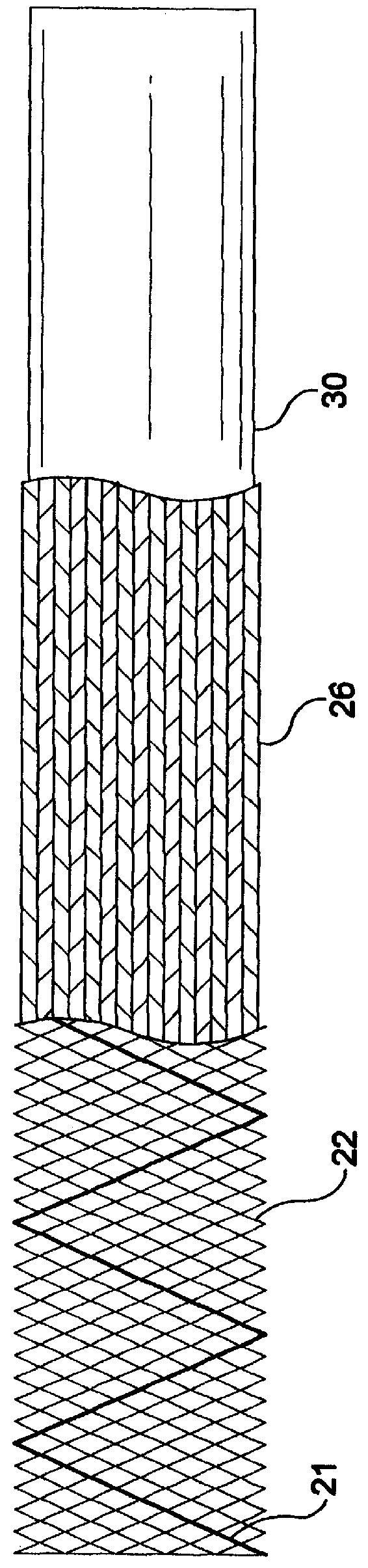

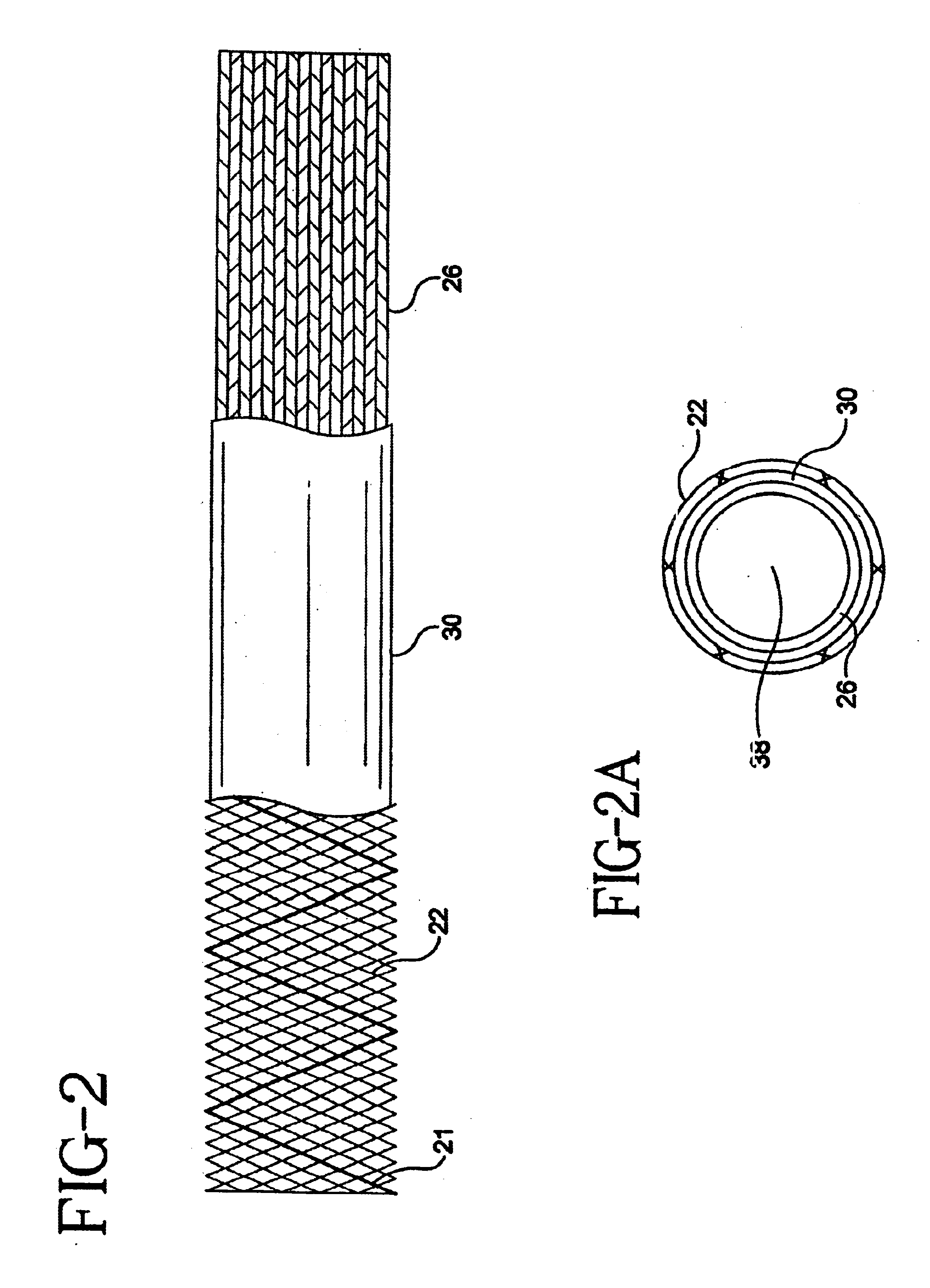

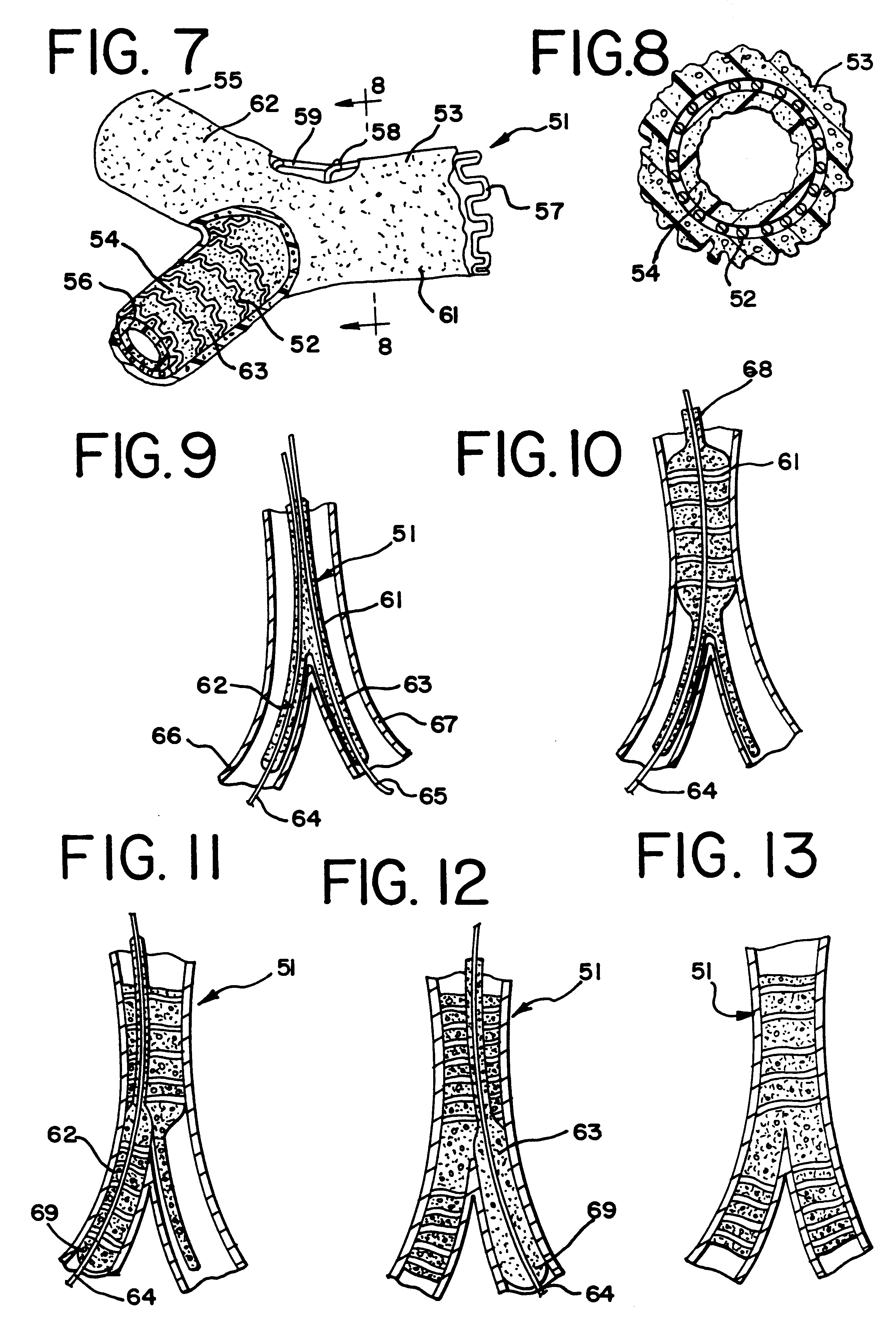

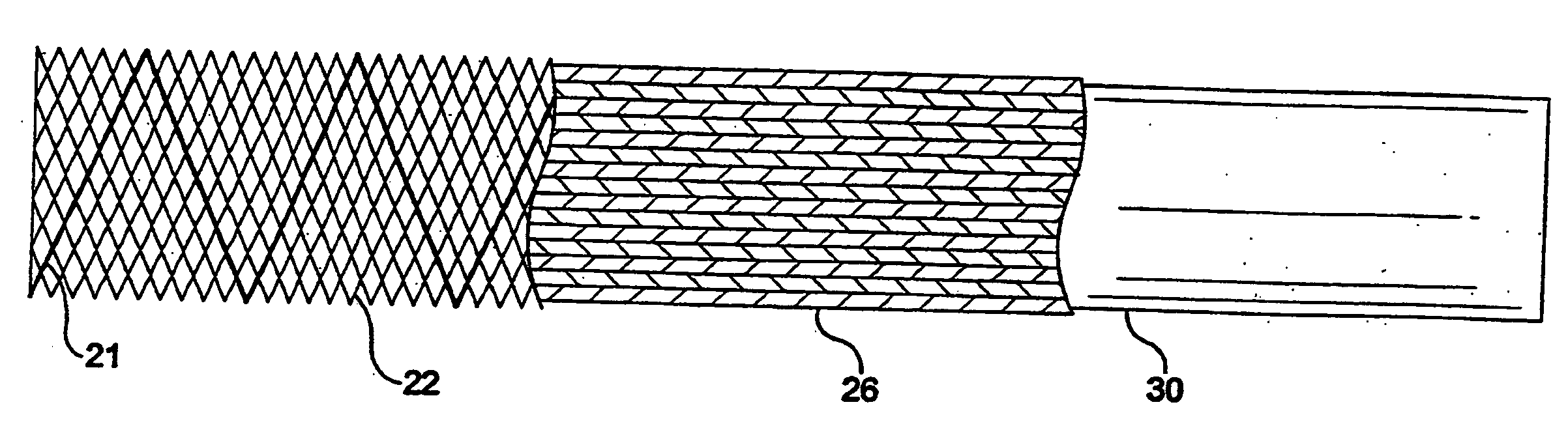

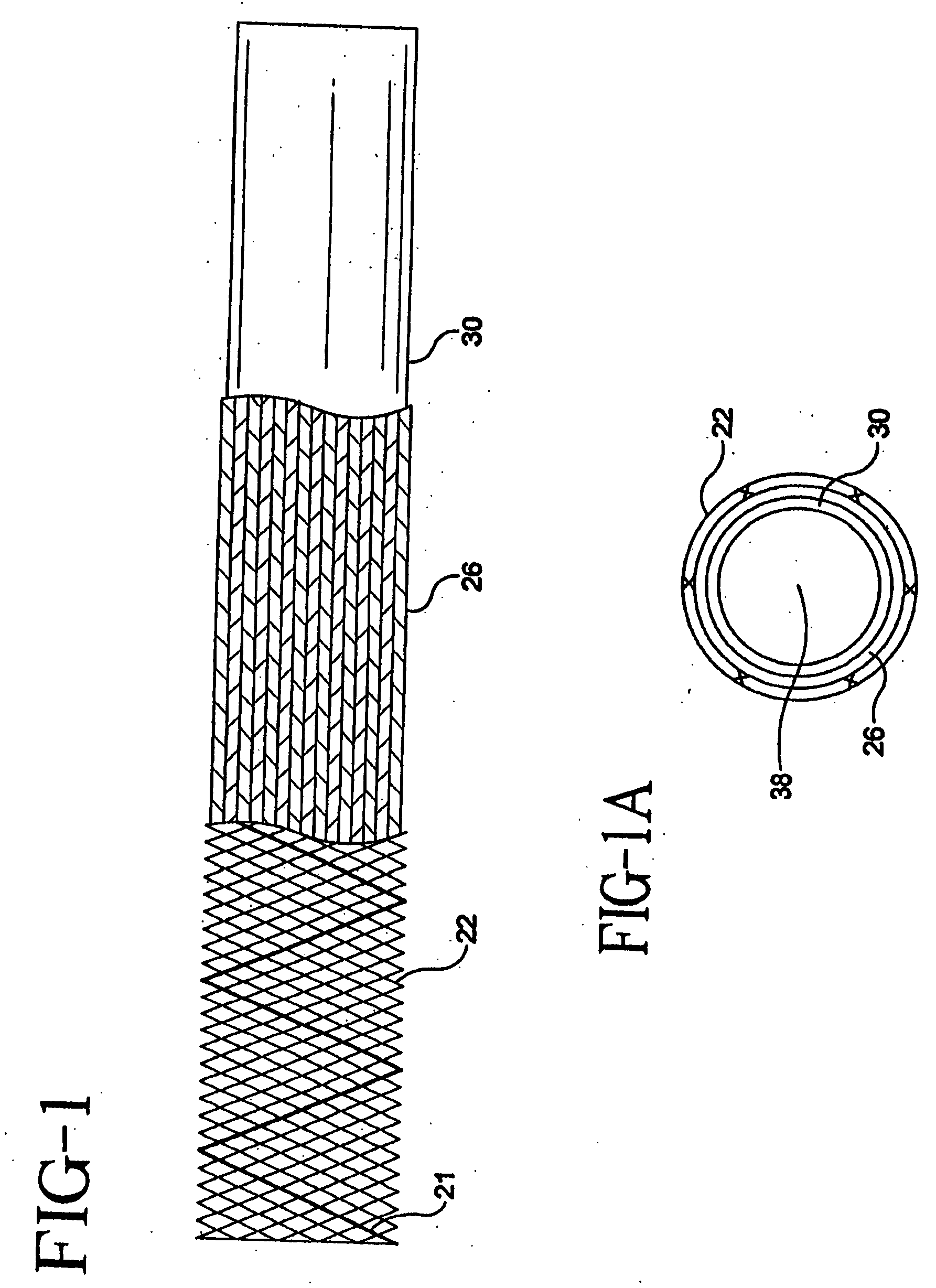

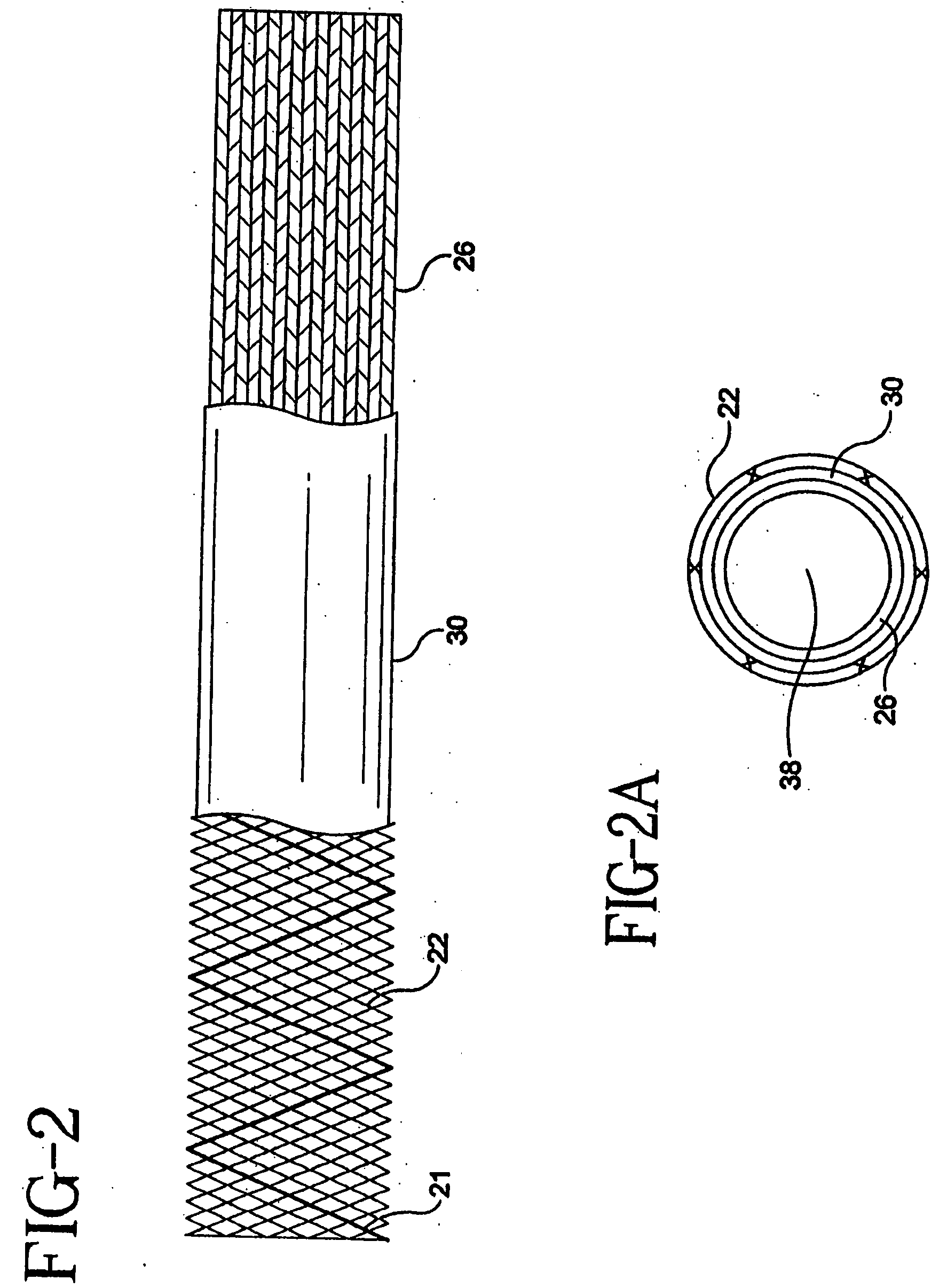

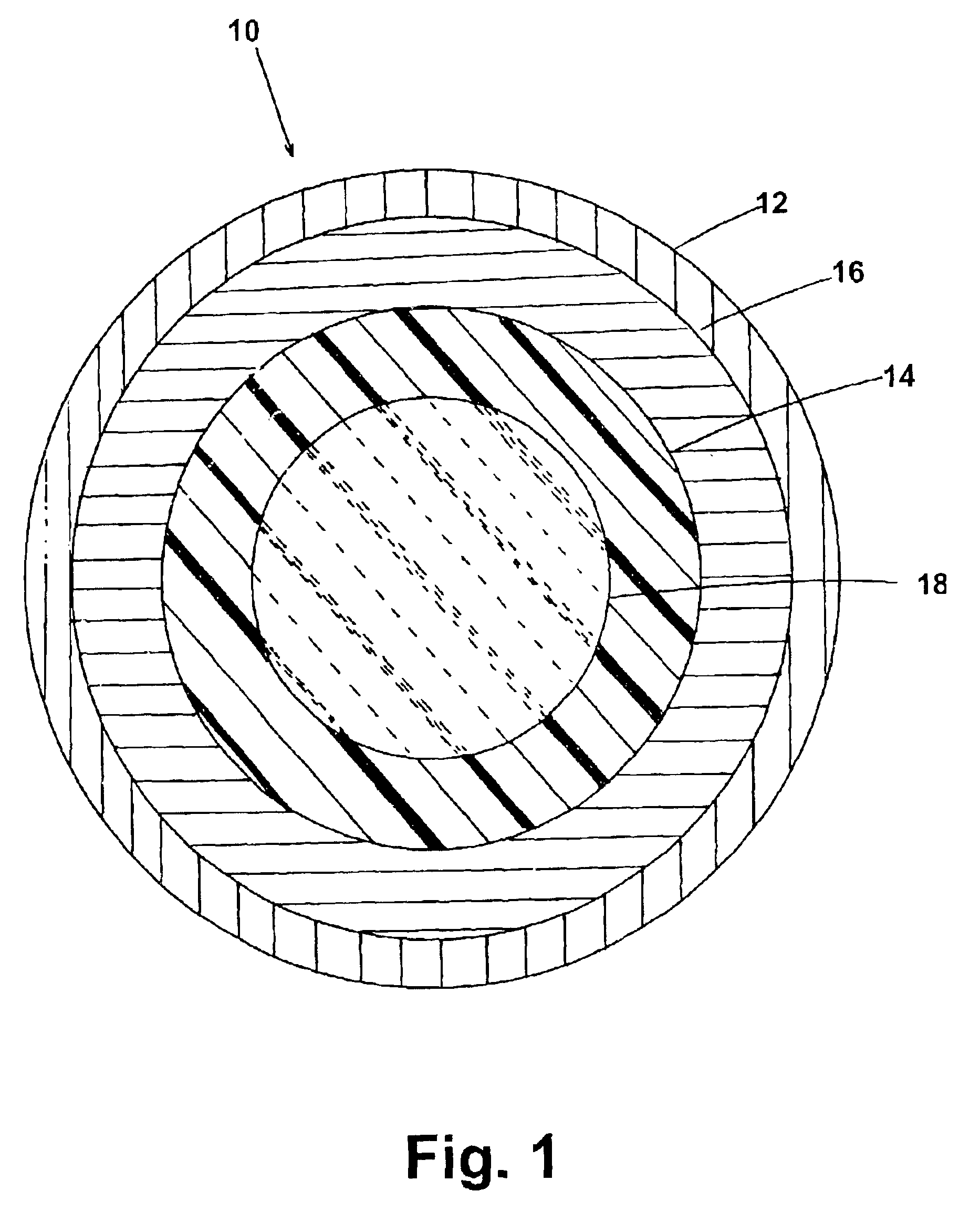

Stent-graft-membrane and method of making the same

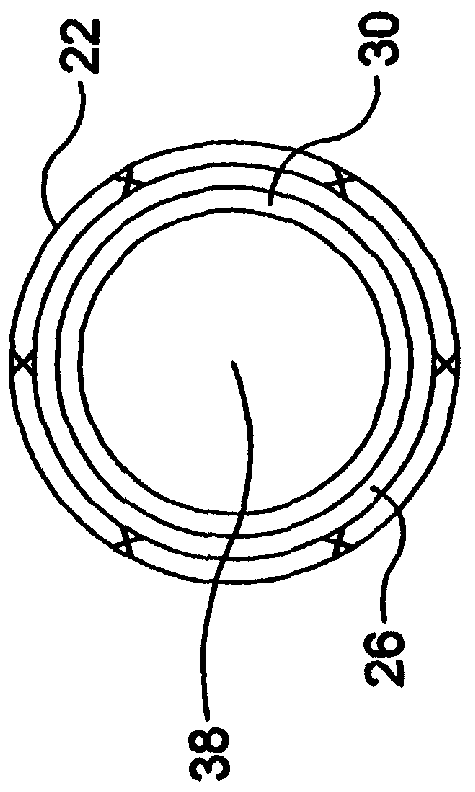

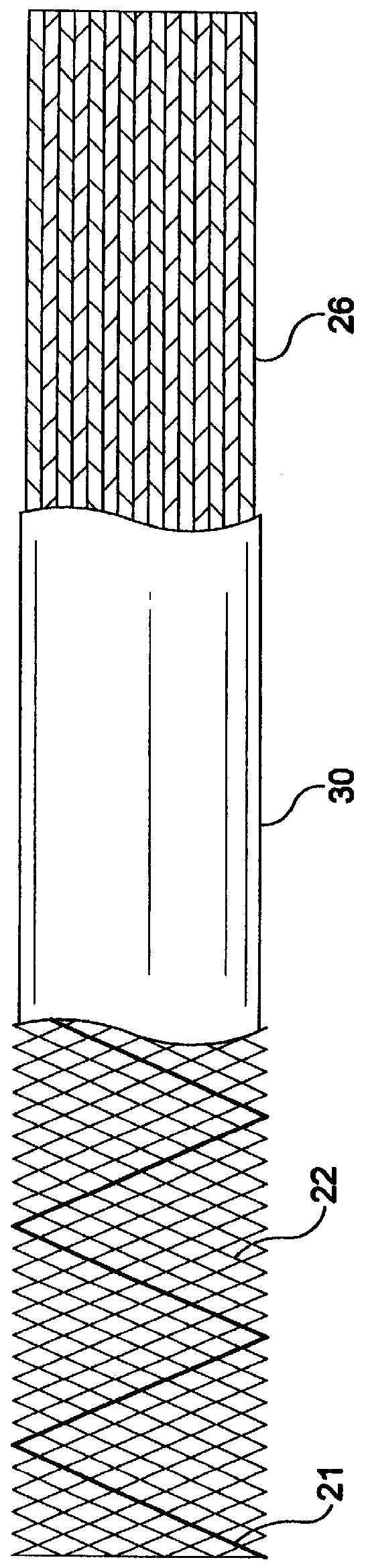

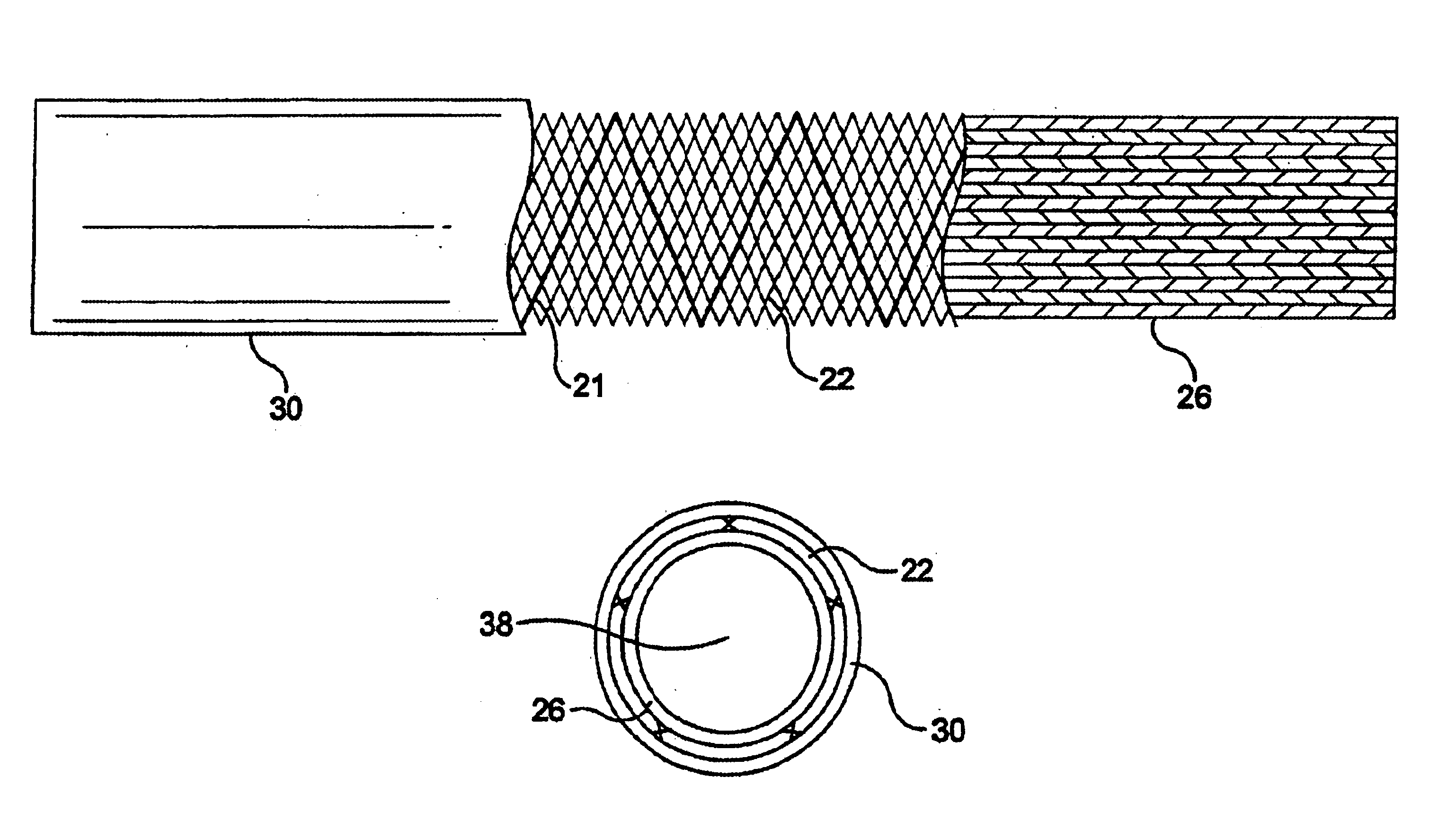

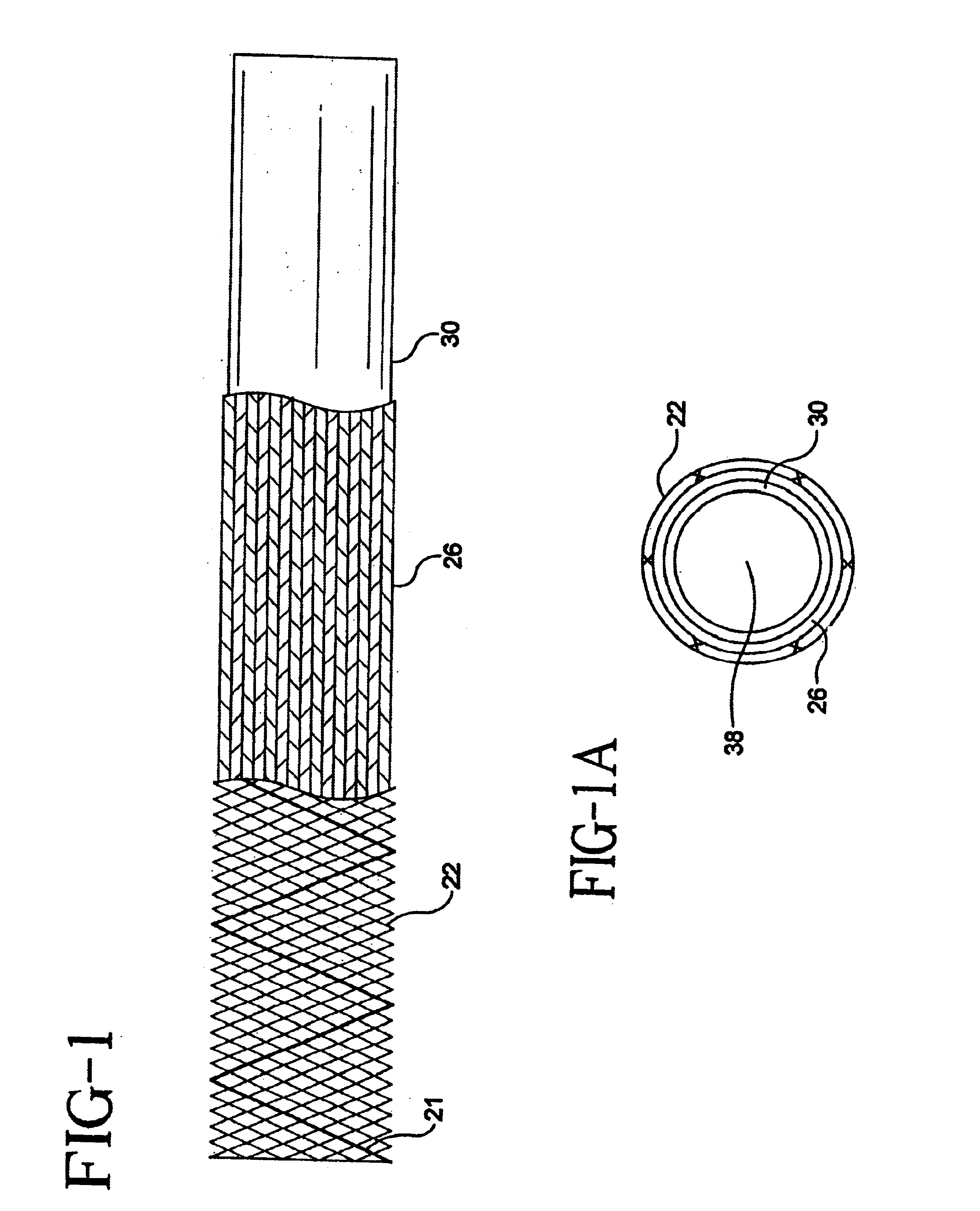

A braided self-expandable stent-graft-membrane made of elongated members forming a generally tubular body. A membrane layer and graft layer are disposed on a endoprosthesis such as a stent. The membrane layer is substantially impermeable to fluids. The outermost layer is biocompatible with the body tissue. The innermost layer is biocompatible with the fluid in the passage. An embodiment includes a graft layer disposed on the inside of a stent and a membrane layer disposed on the outside of the stent. The innermost layer is biocompatible with the fluid in the passage. The stent-graft-membrane is used at a treatment site in a body vessel or organ where it is desirous to exclude a first fluid located outside the endoprosthesis from reaching a second fluid located in the lumen. The membrane may be made of silicone or polycarbonate urethane. The graft may be braided, woven, spun or spray-cast PET, PCU, or PU fibers. The layers may include ePTFE or PTFE.

Owner:LIFEPORT SCI

Stent-graft-membrane and method of making the same

A braided self-expandable stent-graft-membrane made of elongated members forming a generally tubular body. A membrane layer and graft layer are disposed on a endoprosthesis such as a stent. The membrane layer is substantially impermeable to fluids. The outermost layer is biocompatible with the body tissue. The innermost layer is biocompatible with the fluid in the passage. An embodiment includes a graft layer disposed on the inside of a stent and a membrane layer disposed on the outside of the stent. The innermost layer is biocompatible with the fluid in the passage. The stent-graft-membrane is used at a treatment site in a body vessel or organ where it is desirous to exclude a first fluid located outside the endoprosthesis from reaching a second fluid located in the lumen. The membrane may be made of silicone or polycarbonate urethane. The graft may be braided, woven, spun or spray-cast PET, PCU, or PU fibers. The layers may include ePTFE or PTFE.

Owner:LIFEPORT SCI

Expandable supportive endoluminal grafts

Owner:LIFEPORT SCI

Stent-graft-membrane and method of making the same

A braided self-expandable stent-graft-membrane made of elongated members forming a generally tubular body. A membrane layer and graft layer are disposed on a endoprosthesis such as a stent. The membrane layer is substantially impermeable to fluids. The outermost layer is biocompatible with the body tissue. The innermost layer is biocompatible with the fluid in the passage. An embodiment includes a graft layer disposed on the inside of a stent and a membrane layer disposed on the outside of the stent. The innermost layer is biocompatible with the fluid in the passage. The stent-graft-membrane is used at a treatment site in a body vessel or organ where it is desirous to exclude a first fluid located outside the endoprosthesis from reaching a second fluid located in the lumen. The membrane may be made of silicone or polycarbonate urethane. The graft may be braided, woven, spun or spray-cast PET, PCU, or PU fibers. The layers may include ePTFE or PTFE.

Owner:LIFEPORT SCI

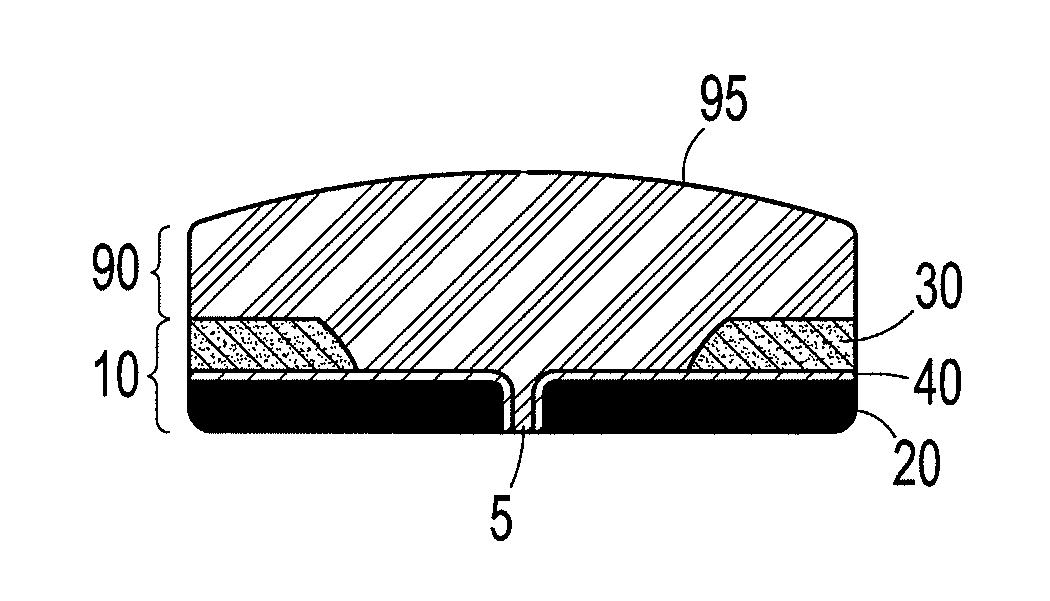

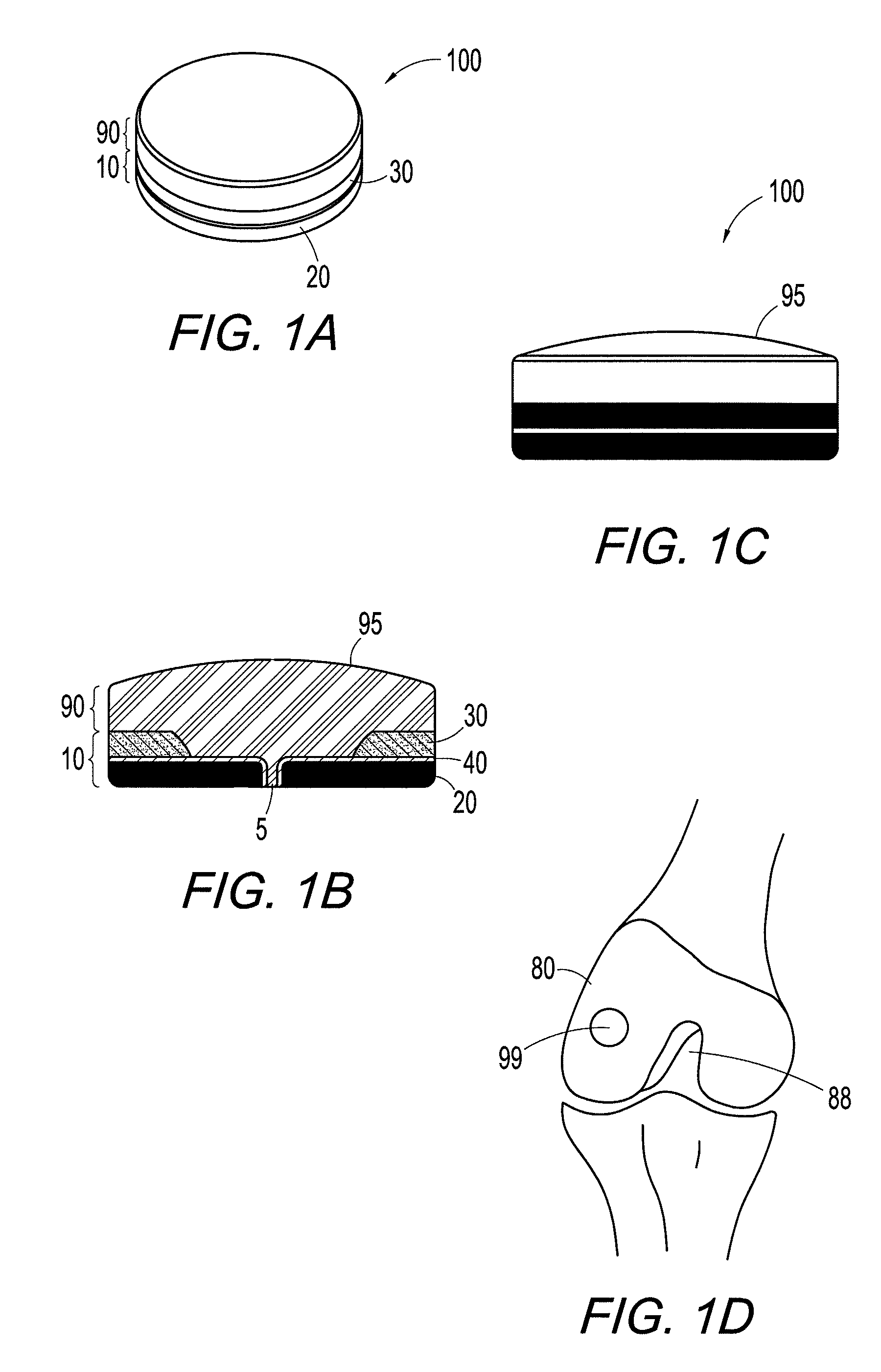

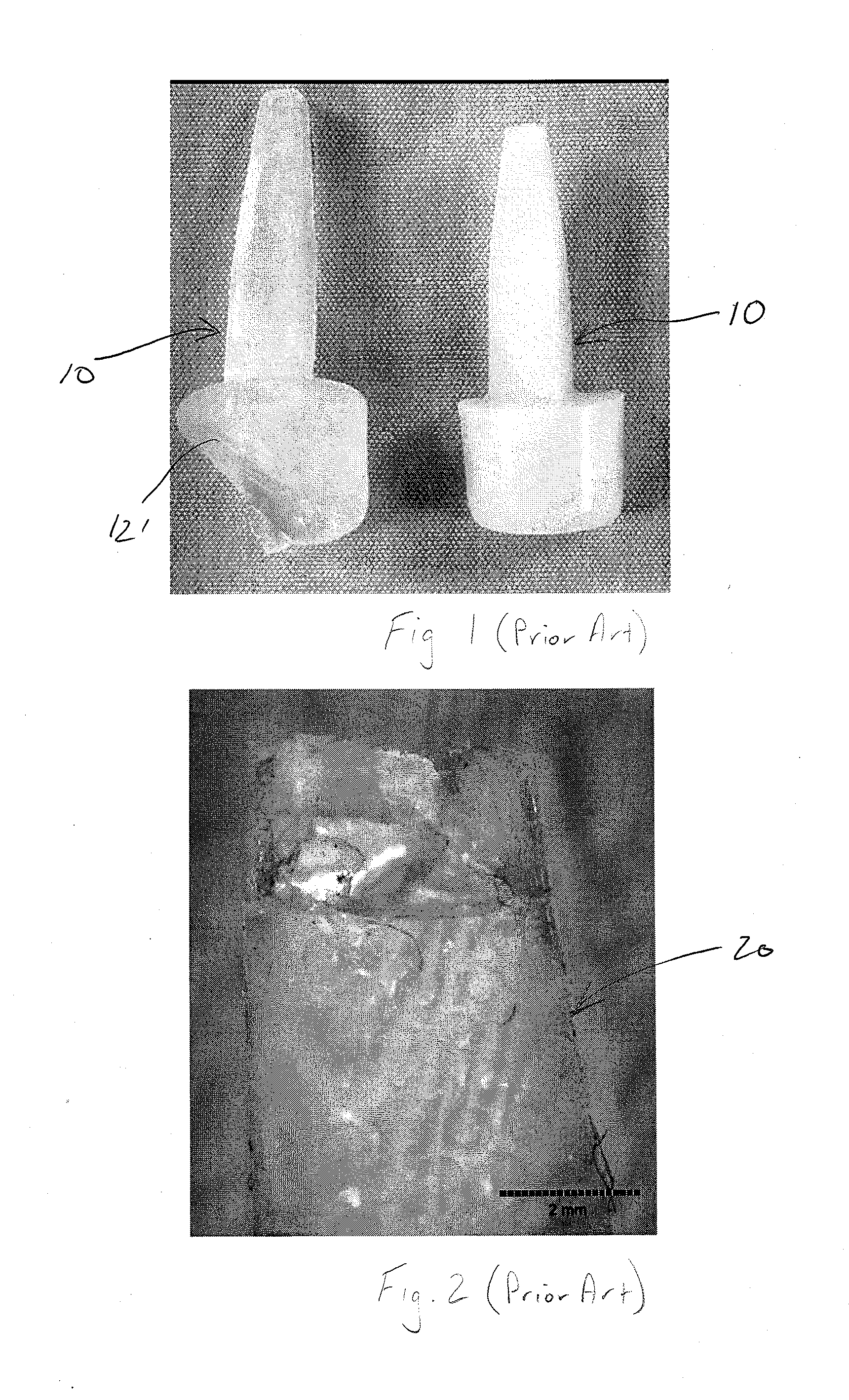

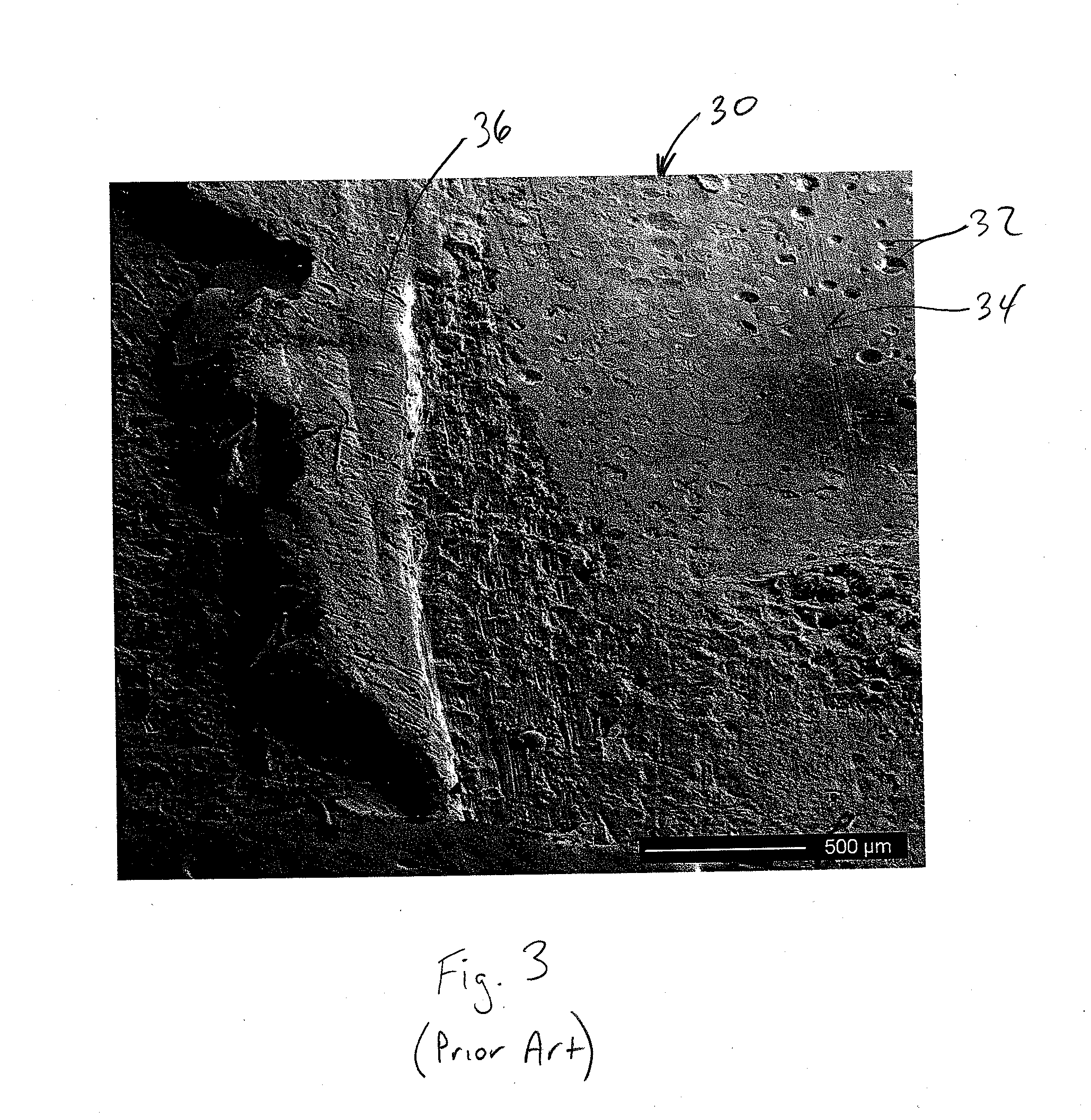

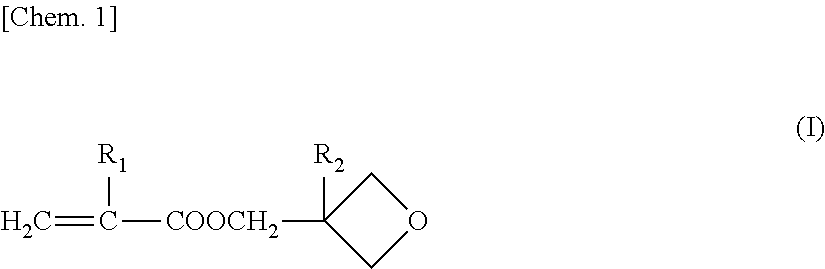

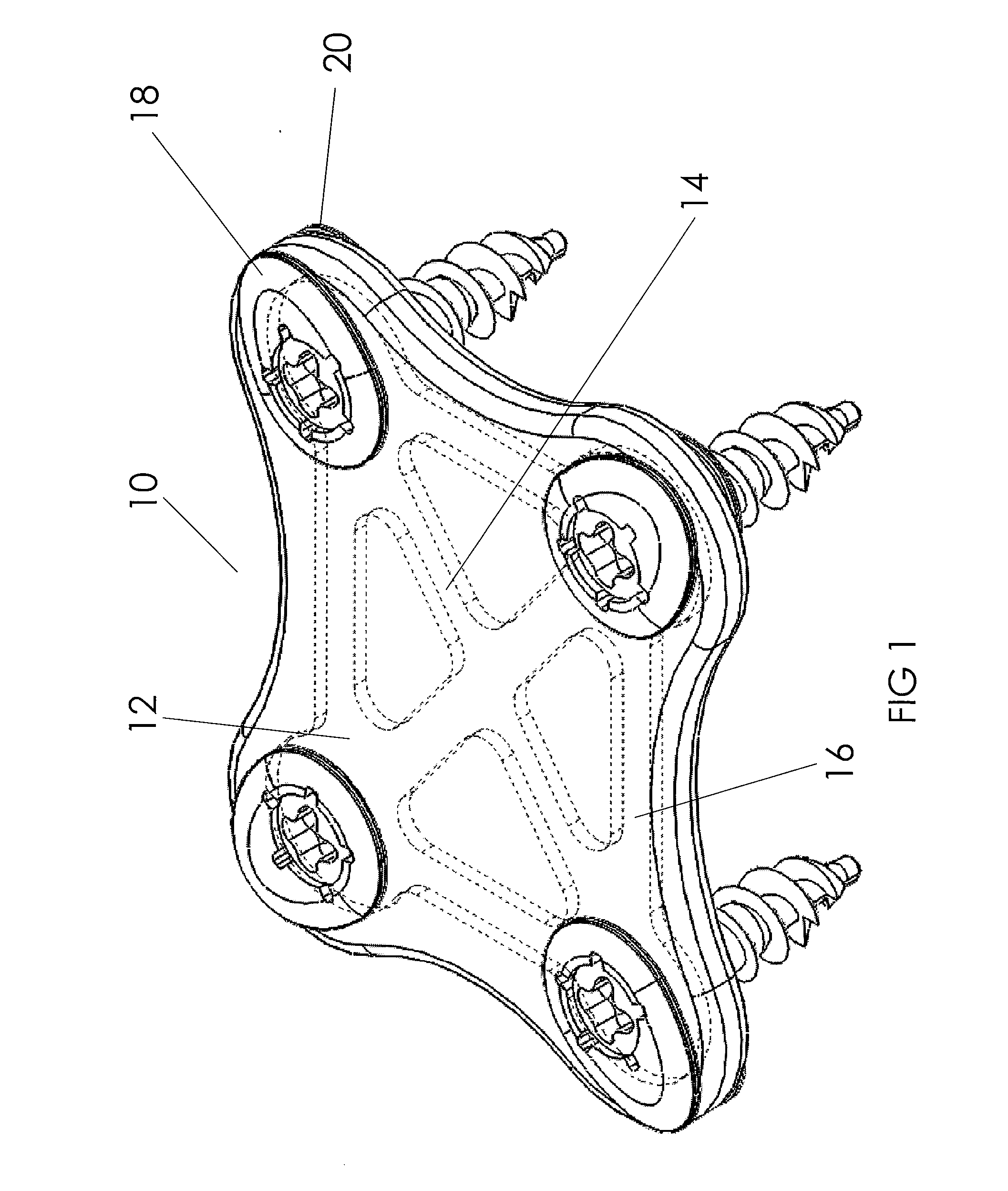

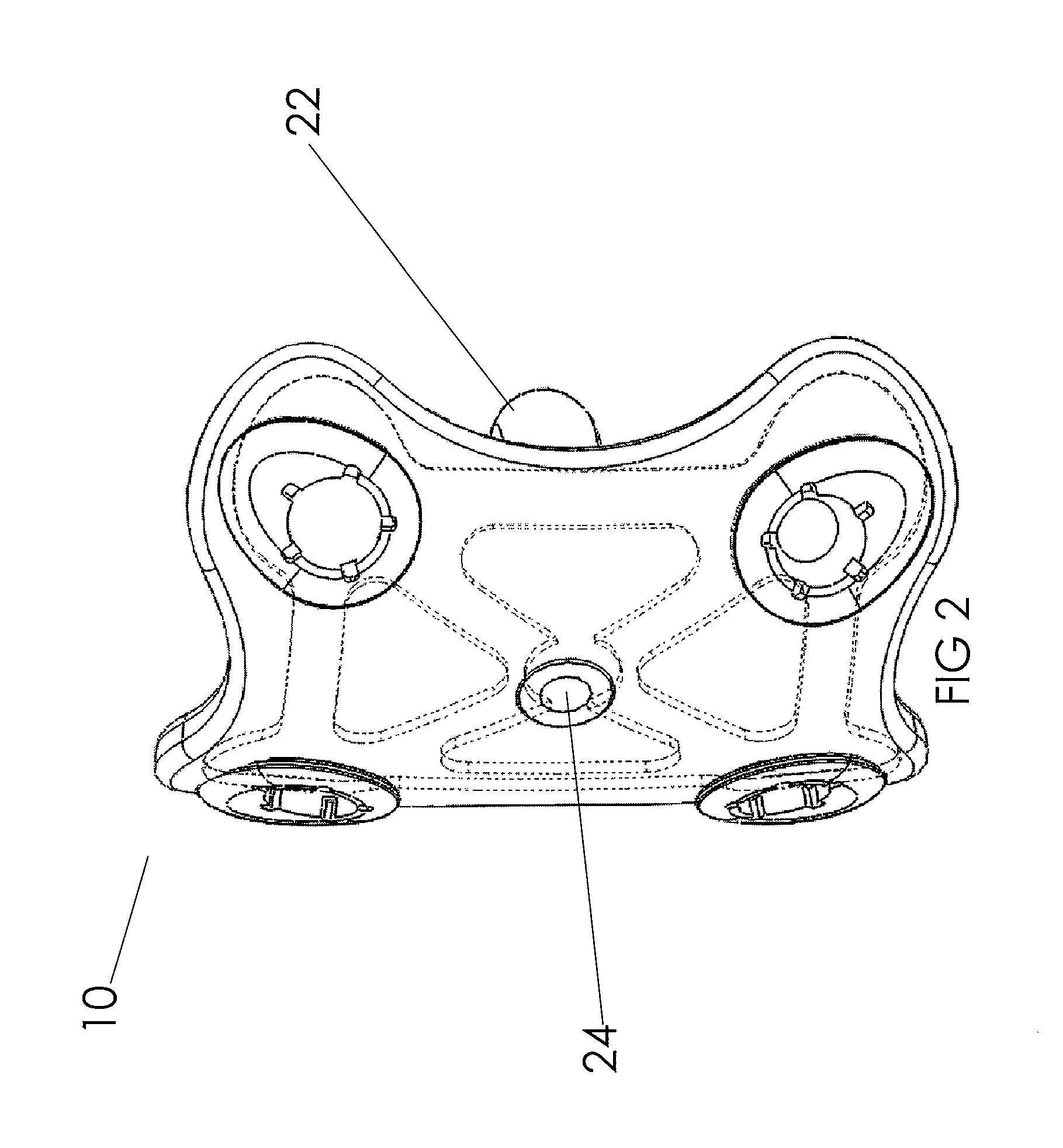

Hybrid polymer/metal plug for treating chondral defects

Osteochondral implants for repair of chondral defects and providing bone fixation through bone ongrowth and / or ingrowth. The implant is provided with a base allowing for bone ongrowth and / or ingrowth and a top attached to the base, the top being formed of a material having a compressive resistance similar to that of the cartilage. The material of the top is polycarbonate urethane, for example. The base may comprise a porous substrate for bony ingrowth formed of metal or PEEK and having a pattern porosity about similar to the porosity of cancellous bone. One side of the top attaches to the base for stability, and the other side of the top forms a surface for articulating with the opposing cartilage surface of the joint.

Owner:ARTHREX

Golf balls with thermoplastic polycarbonate-urethane copolymers

InactiveUS6855793B2Improve surface propertiesImprove propertiesGolf ballsSolid ballsEngineeringGolf Ball

A golf ball comprising a core, a cover, and, optionally, at least one intermediate layer disposed between the core and the cover, wherein at least one of the cover or the intermediate layer comprise a thermoplastic polycarbonate-urethane copolymer.

Owner:ACUSHNET CO

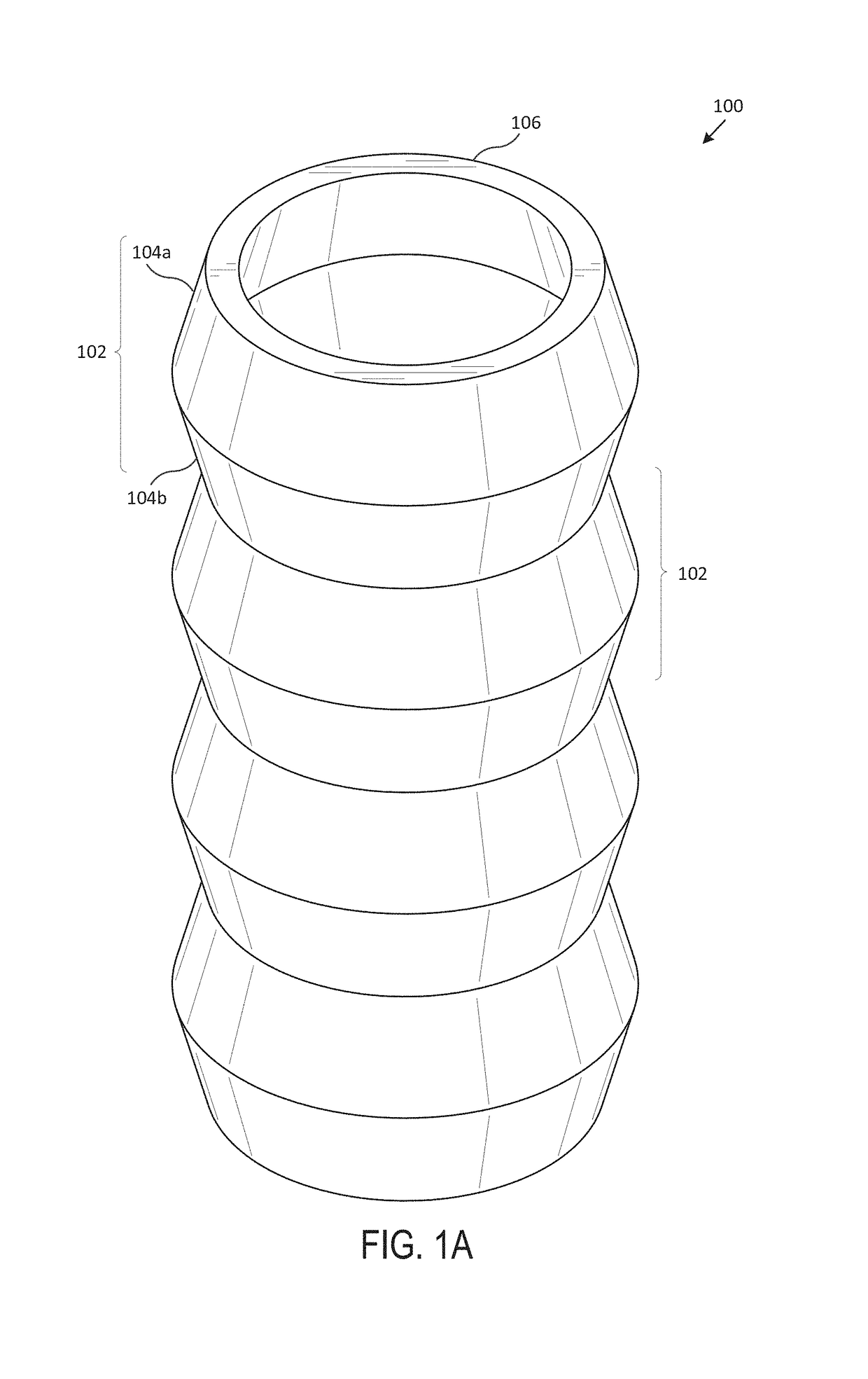

Medical devices and methods for producing the same

The present disclosure relates generally to medical devices, including airway stents, and additive manufacturing (3D printing) processes for producing the same. Using certain materials and novel printing techniques, the present systems and methods can directly print nearly any size or shape medical device in a few hours. For example, in certain embodiments, the present systems and methods leverage fused deposition modeling (“FDM”) and polycarbonate urethane (“PCU”) to produce custom medical devices, including airway stents.

Owner:RESTOR3D INC

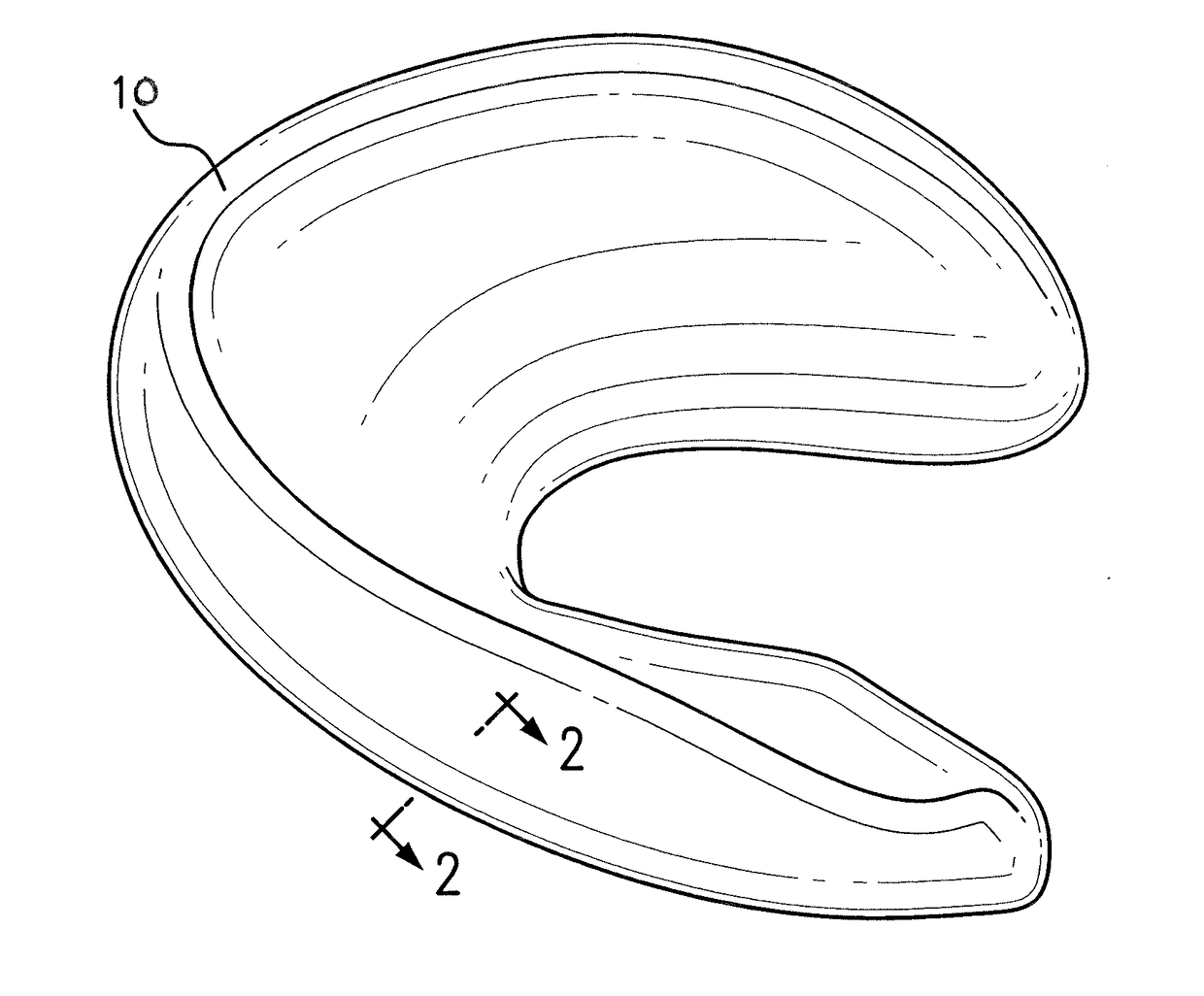

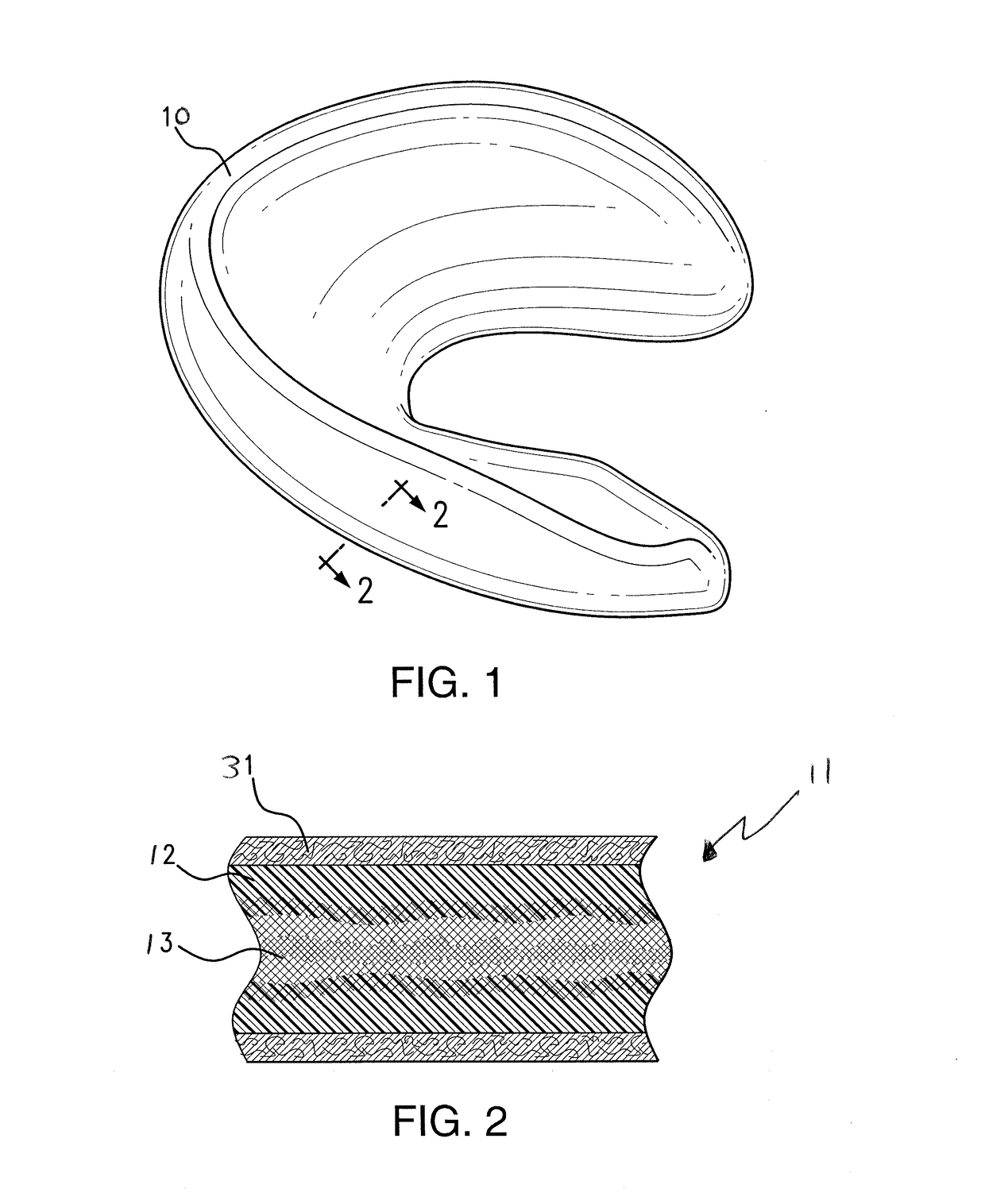

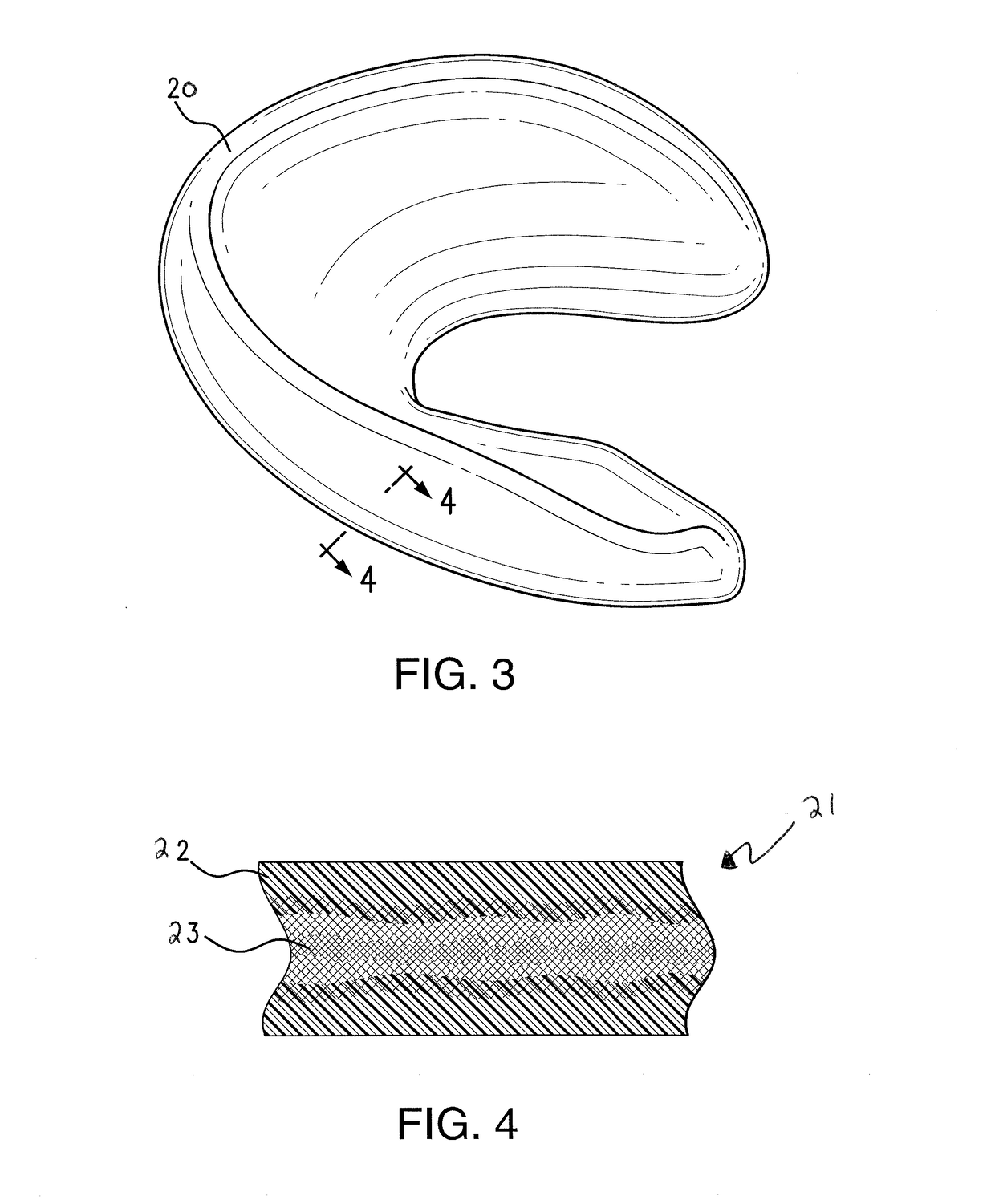

Artificial meniscus

An artificial meniscus using a thermoplastic for the base material, which is reinforced with an inert material. In a preferred embodiment, the reinforcement is provided by Kevlar® fibers, and the matrix is made out of polycarbonate-urethane (PCU). In an alternate embodiment, the PCU can also be surrounded by a polycaprolactone (PCL) scaffold that is infused with human growth proteins so that when the artificial meniscus is implanted, stem cells in the body are stimulated to ensure the meniscus is properly secured.

Owner:PERSAUD PHILIP A

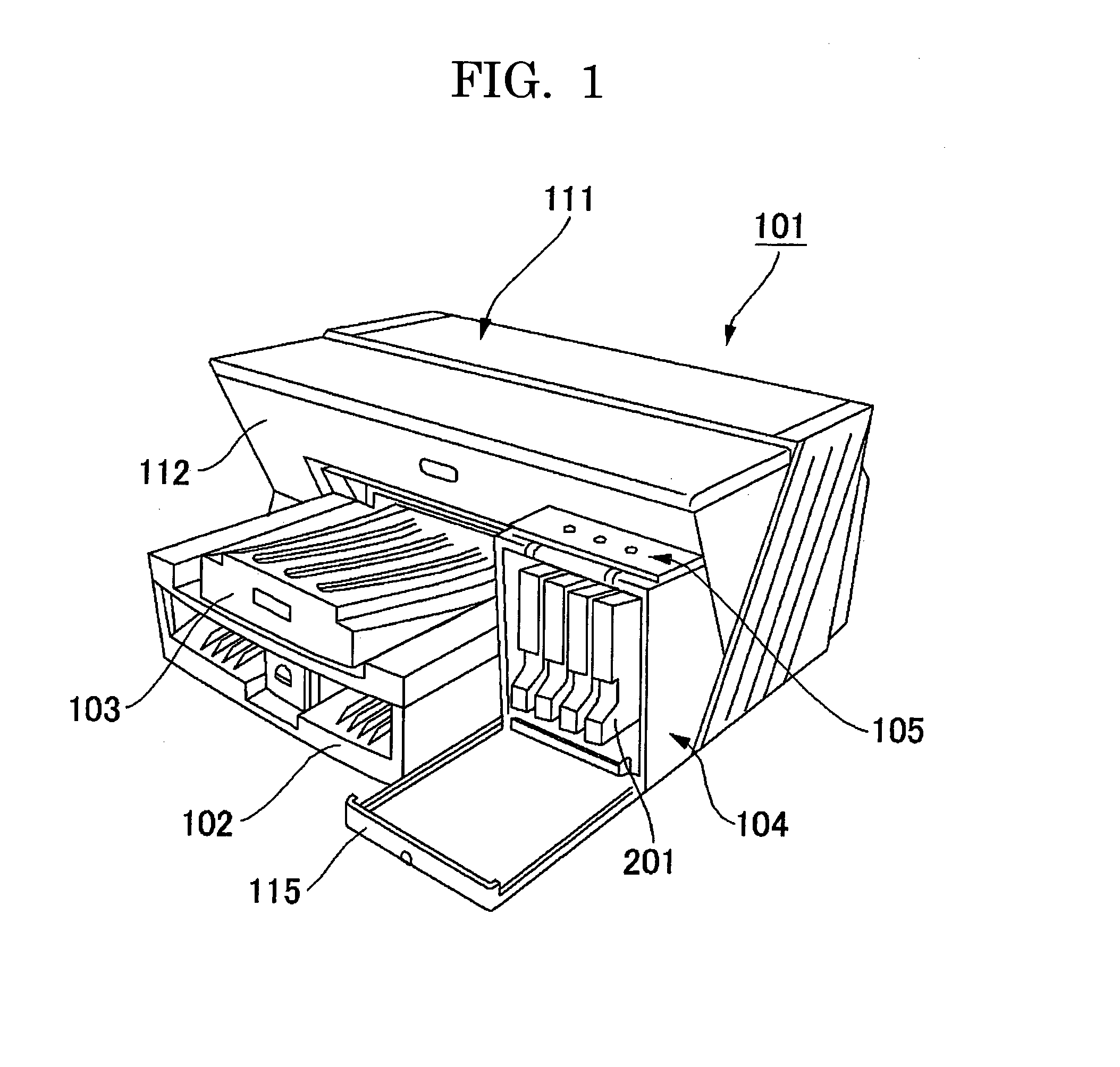

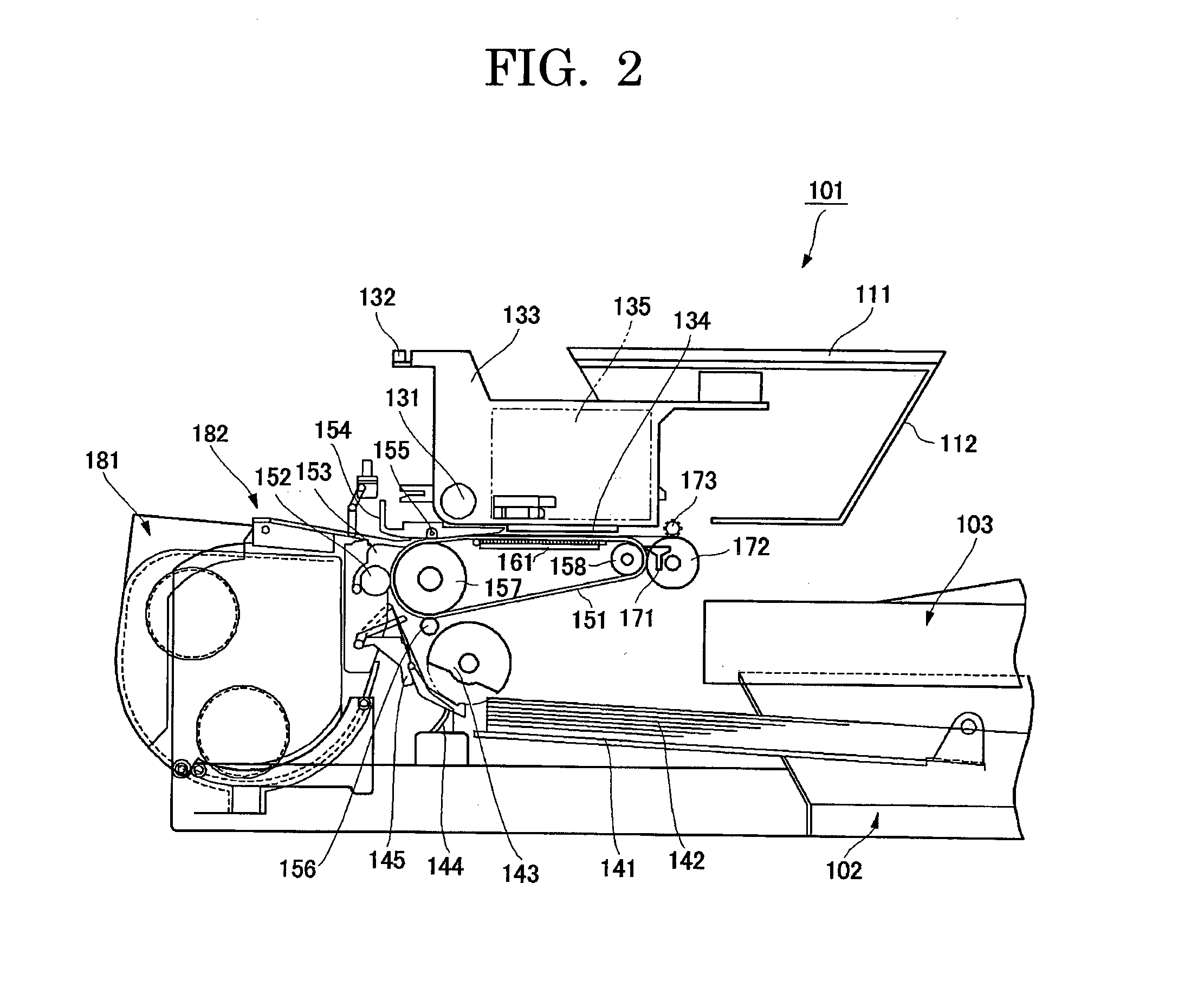

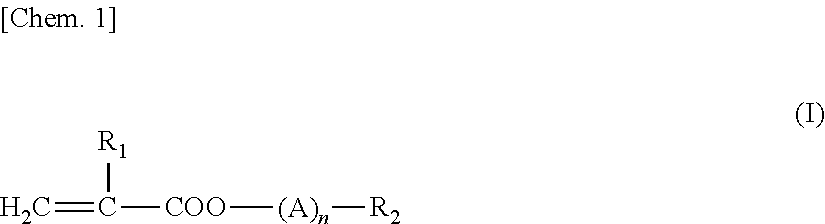

Inkjet ink, inkjet recording method and ink recorded matter

ActiveUS20150361282A1High glossinessHigh image densityNon-fibrous pulp additionLayered productsOrganic solventBoiling point

An inkjet ink, containing: water; a water-soluble organic solvent; a pigment; and polycarbonate urethane resin particles, wherein the water-soluble organic solvent contains 50% by mass or more of a diol compound, and wherein the water-soluble organic solvent contains 50% by mass or more of a water-soluble organic solvent having a boiling point of 200° C. or less.

Owner:RICOH KK +1

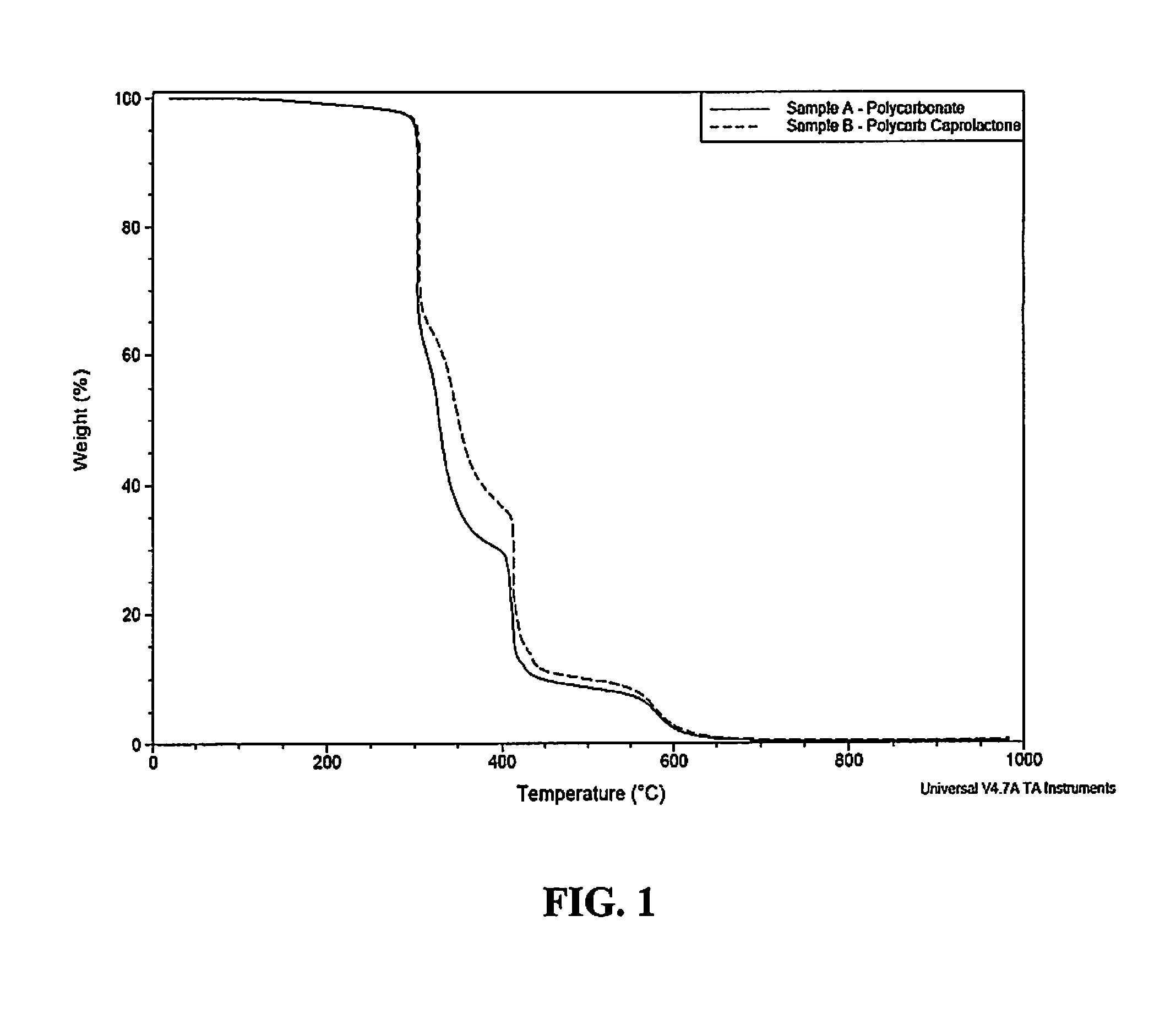

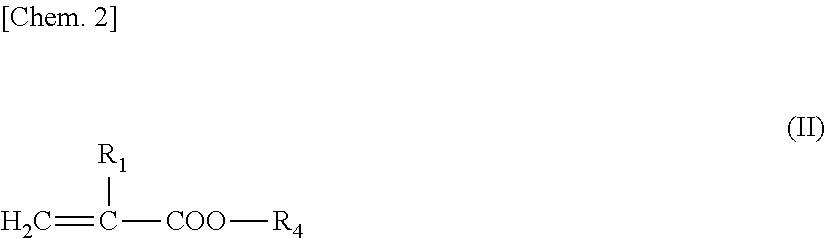

High temperature resistance, radiation curable maskant for metal substrates

A method for shielding a metal substrate surface during the application of heat to the surroundings of the substrate which comprises. A liquid maskant composition is formed which comprises: a) at least one of a polycarbonate urethane diacrylate oligomer, a polycarbonate urethane dimethacrylate oligomer, a polycarbonate caprolactone urethane diacrylate oligomer, or a polycarbonate caprolactone urethane dimethacrylate oligomer; b) a reactive diluent capable of free radical polymerization; and c) a photoinitiator capable of generating free radicals when exposed to actinic radiation. The maskant composition is applied onto a surface of the substrate. The maskant composition is then exposed to sufficient actinic radiation to polymerize or crosslink the composition into a dried maskant. In use the dried maskant is heated on the substrate to a temperature of from about 400° F. to about 600° F. for from about 20 minutes to about 30 minutes, and then the maskant is removed.

Owner:DYMAX

Vessel protection device

The present disclosure relates to a vessel / tissue protection device having a polymer coated reinforcing layer. The polymer can comprise a biocompatible polymer that will not promote tissue in-growth or attachment, such as segmented polyurethane, polycarbonate urethane, polyether urethane, polyacrylonitrile, etc. The reinforcing layer can comprise any suitable woven, non-woven, knitted, or braided reinforcing polymer, fabric, or foil that is biocompatible and capable of holding a suture, staple, or other attachment device.

Owner:REPLICATION MEDICAL

Preparation method for polyurethane adhesive applied to protective film

ActiveCN104558503AImprove hydrolysis resistanceGood flexibilityFilm/foil adhesivesPolyureas/polyurethane adhesivesTectorial membranePolyurethane adhesive

The invention discloses a preparation method for a polyurethane adhesive applied to a protective film. The preparation method specifically comprises the following steps: dissolving polyether polyol and hexamethylene diisocyanate in methylbenzene for prepolymerization under the condition of using organic tin as a catalyst; after the prepolymerization is completed, adding a mixture of polycarbonate polyol and methylbenzene for chain extension reaction to obtain colorless transparent polyurethane adhesive main agent. The prepared polyurethane adhesive applied to the protective film has the the advantages of both polyether urethane and polycarbonate urethane, such as outstanding hydrolysis resistance and excellent balance between flexibility and rigidity; the protective film with the polyurethane adhesive has the advantages of low viscosity, excellent exhaust performance, rime fog resistance and the like; furthermore, the preparation conditions of the adhesive are mild, and the preparation of the adhesive does not need special devices and only needs the traditional stirring and hydrothermal conditions; industrial production is facilitated.

Owner:CYBRID TECHNOLOGIES INC

Battery separator and battery using the same

ActiveUS20110135989A1Improve antioxidant capacityAdhesivenessFinal product manufacturePrimary cellsPorous substrateHydrogen

The present invention relates to a battery separator including: a porous substrate; and a layer of a crosslinked polymer supported on at least one surface of the porous substrate, in which the crosslinked polymer is obtained by reacting (a) a reactive polymer having, in the molecule thereof, a reactive group containing active hydrogen with (b) a polycarbonate urethane prepolymer terminated by an isocyanate group.

Owner:NITTO DENKO CORP

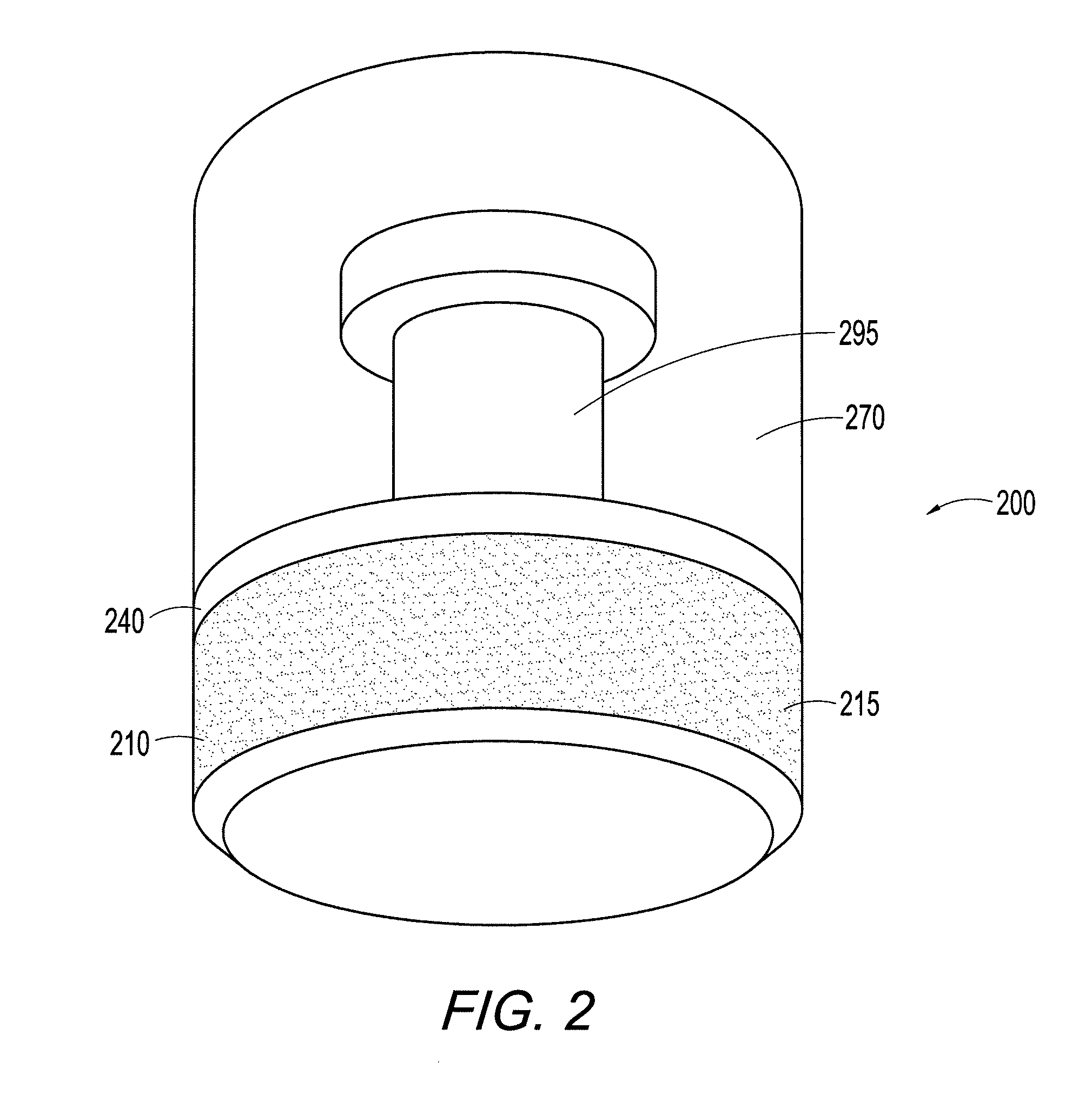

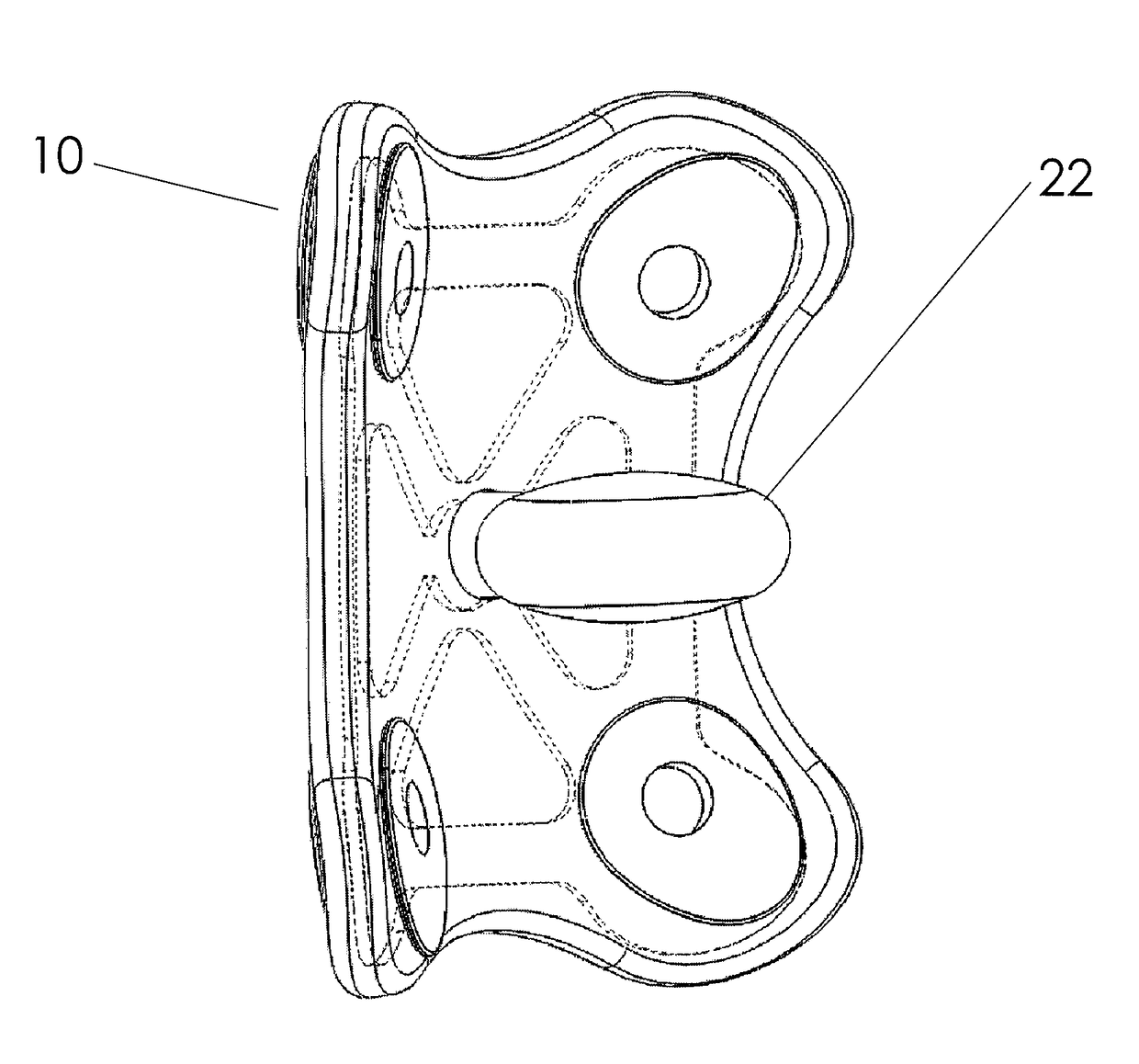

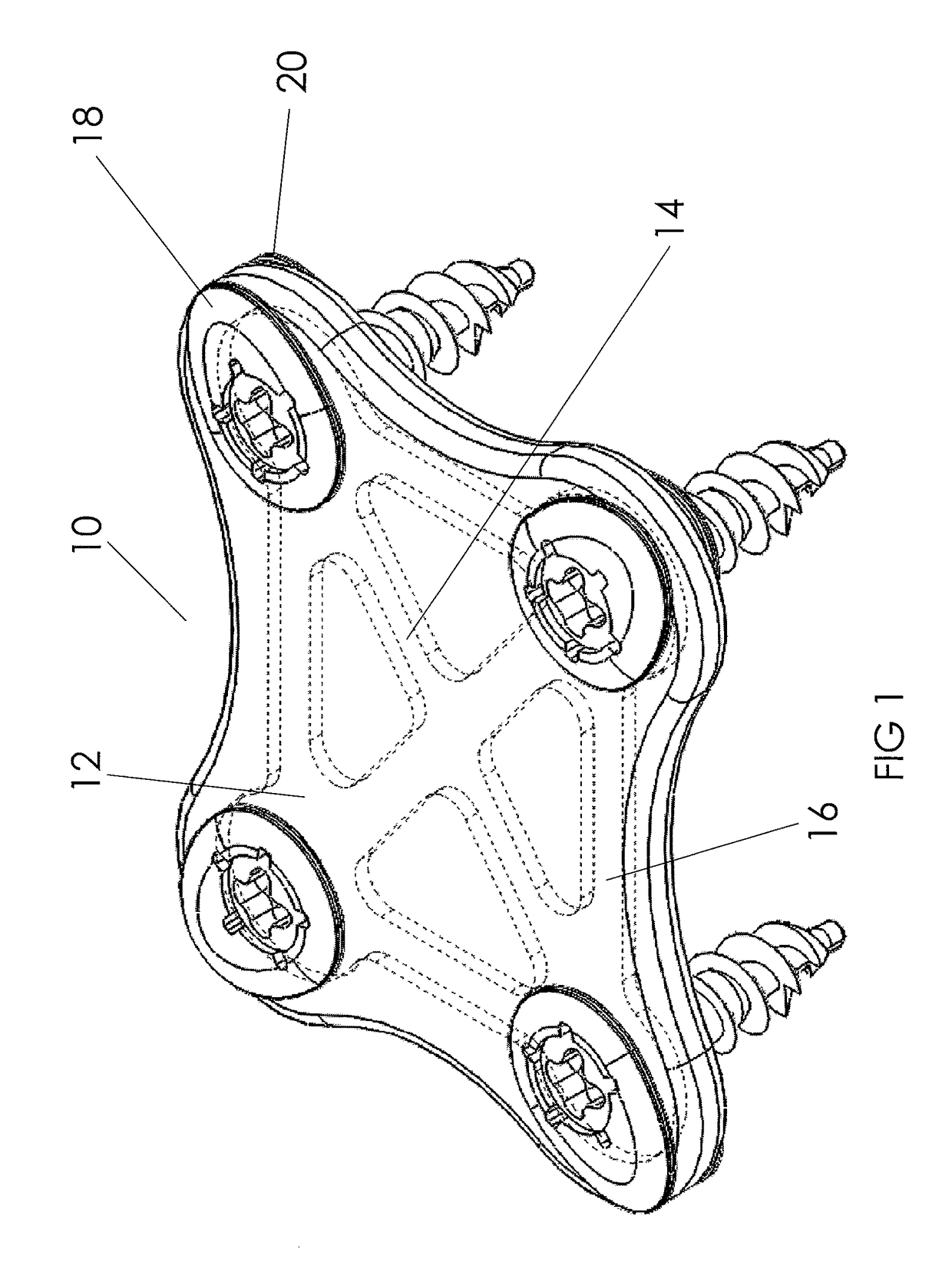

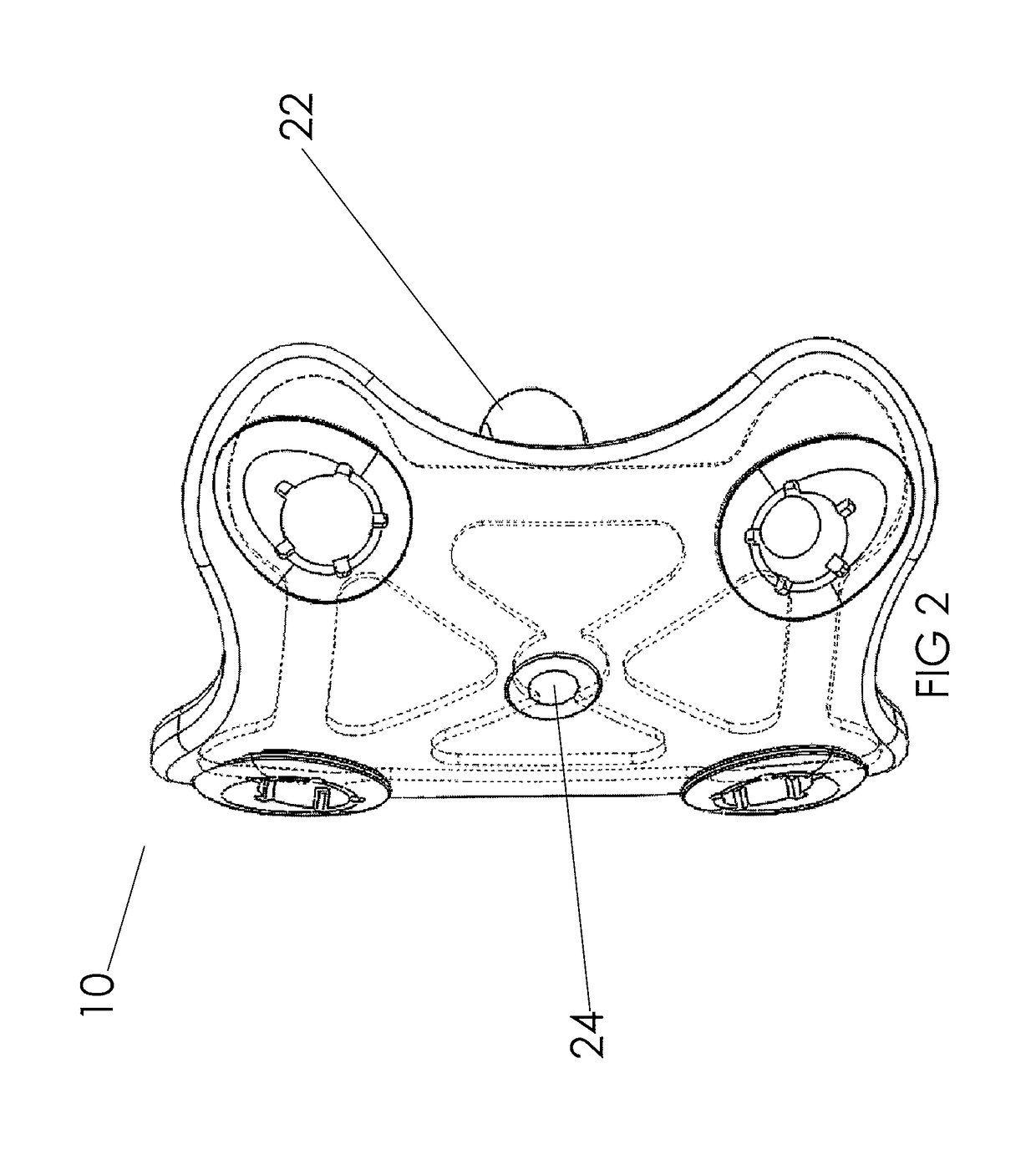

Polycarbonate urethane joint implant

InactiveUS20130226306A1Superior wear qualityRelieve stiffnessFinger jointsAnkle jointsPolycarbonateTarsal Joint

A compressive force and compressive-shear force joint implant including a head defining at least one wear contact surface. At least the at least one wear contact surface is manufactured from a polycarbonate urethane material. The implant may further include a stem extending from the head opposite of the wear contact surface. The head may also be configured to define a second wear contact surface distinct from the first wear contact surface.

Owner:REMI SCI

Battery separator and battery using the same

ActiveUS20110135988A1Improve antioxidant capacityAdhesivenessSolid electrolytesFinal product manufacturePorous substratePolymer science

The present invention relates to a battery separator including: a porous substrate; and a layer of a crosslinked polymer supported on at least one surface of the porous substrate, in which the crosslinked polymer is obtained by reacting (a) a reactive polymer having, in the molecule thereof, a first reactive group containing active hydrogen and a second reactive group having cationic polymerizability with (b) a polycarbonate urethane prepolymer terminated by an isocyanate group.

Owner:NITTO DENKO CORP

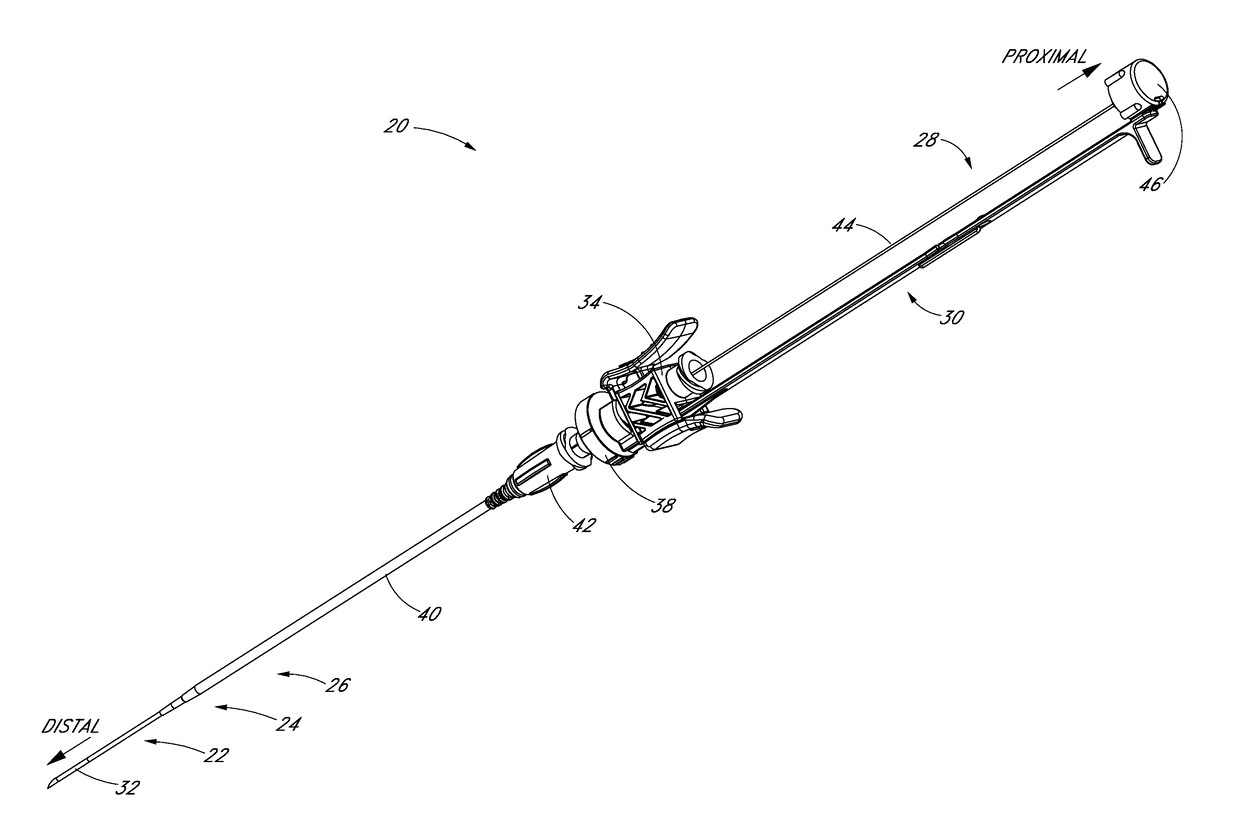

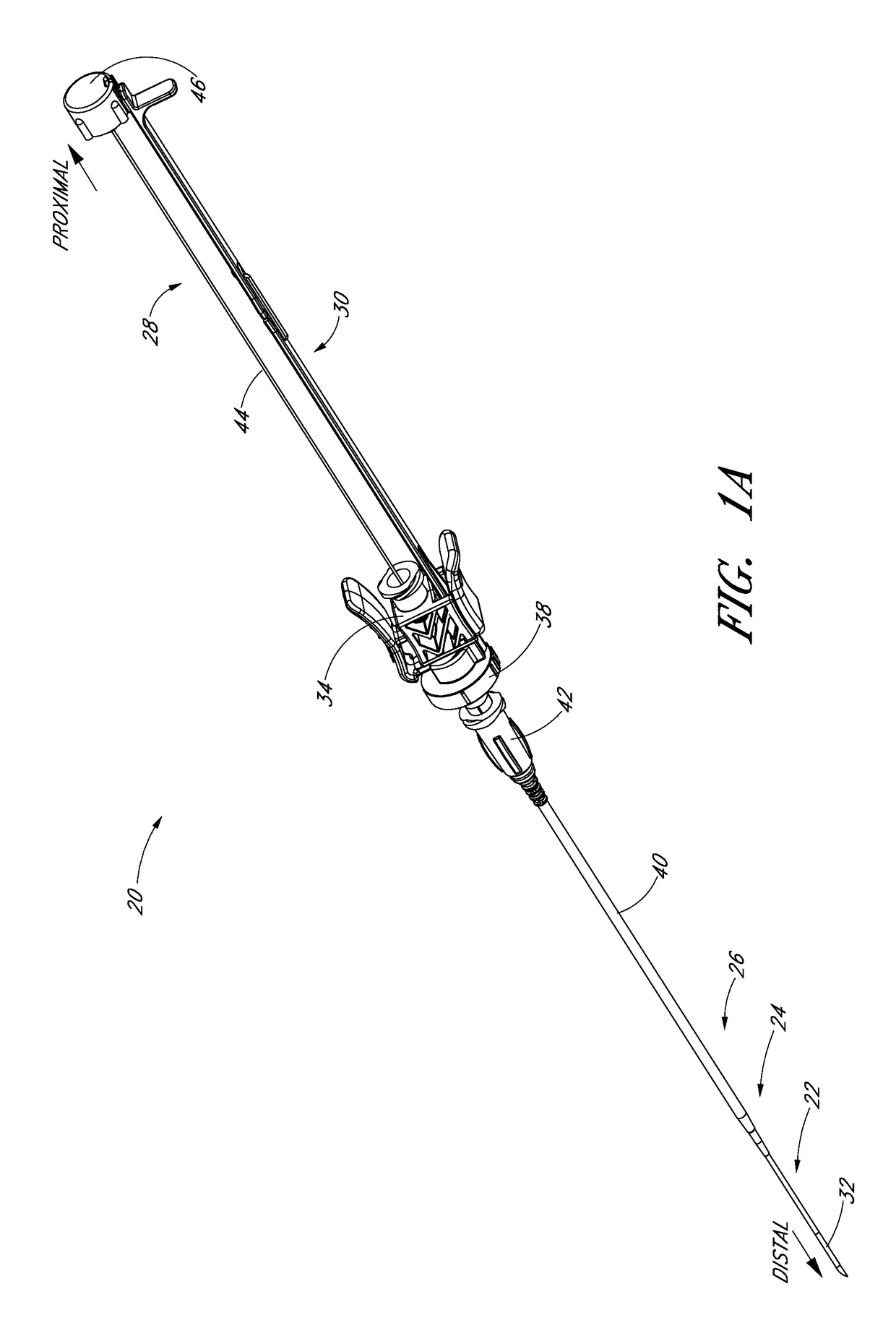

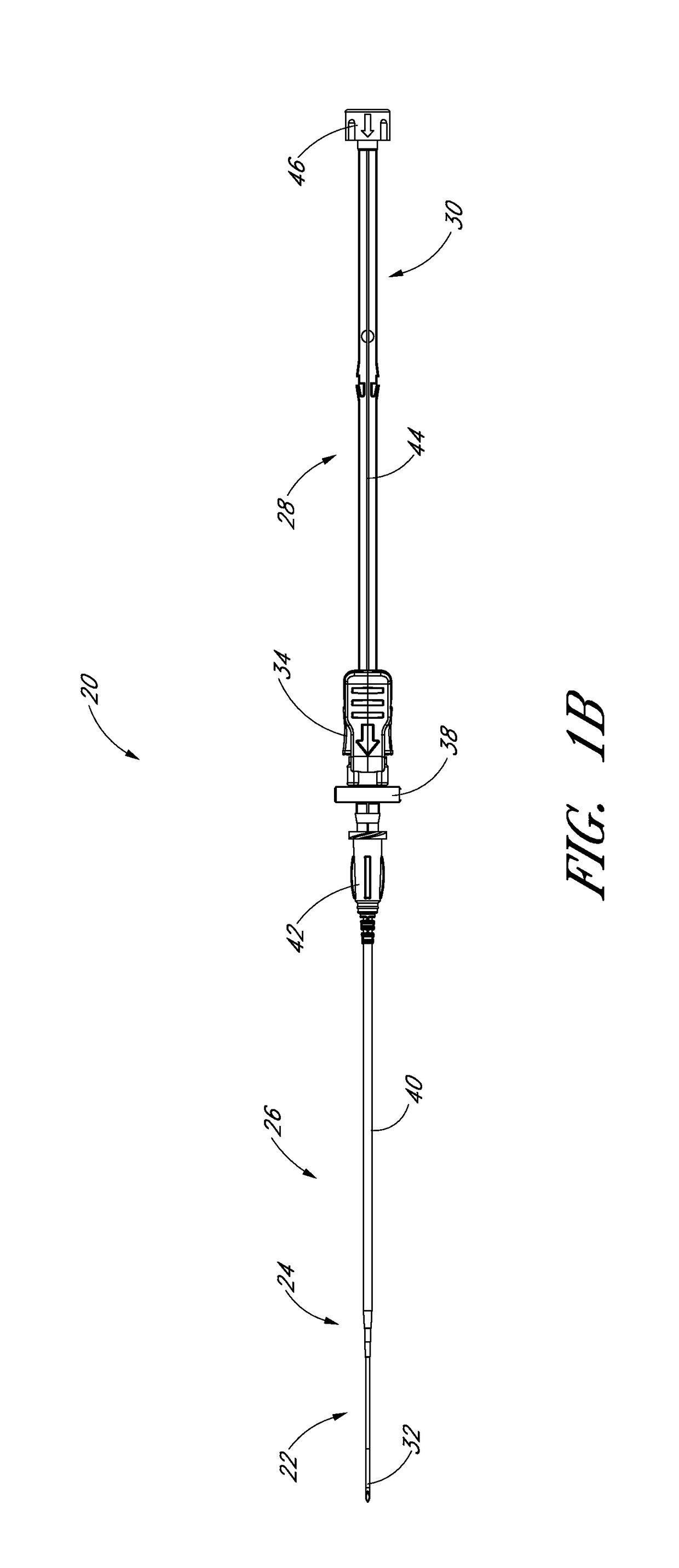

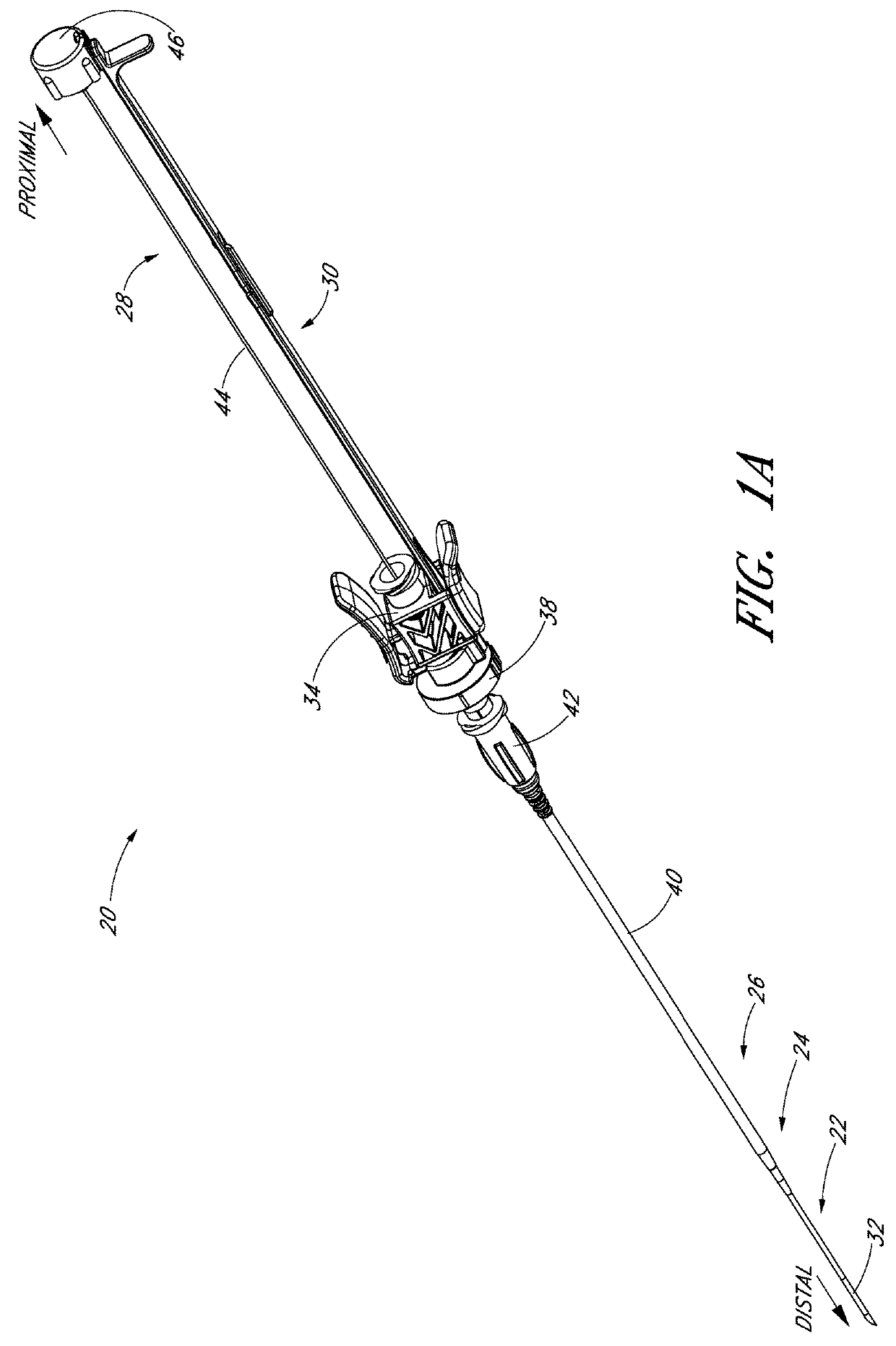

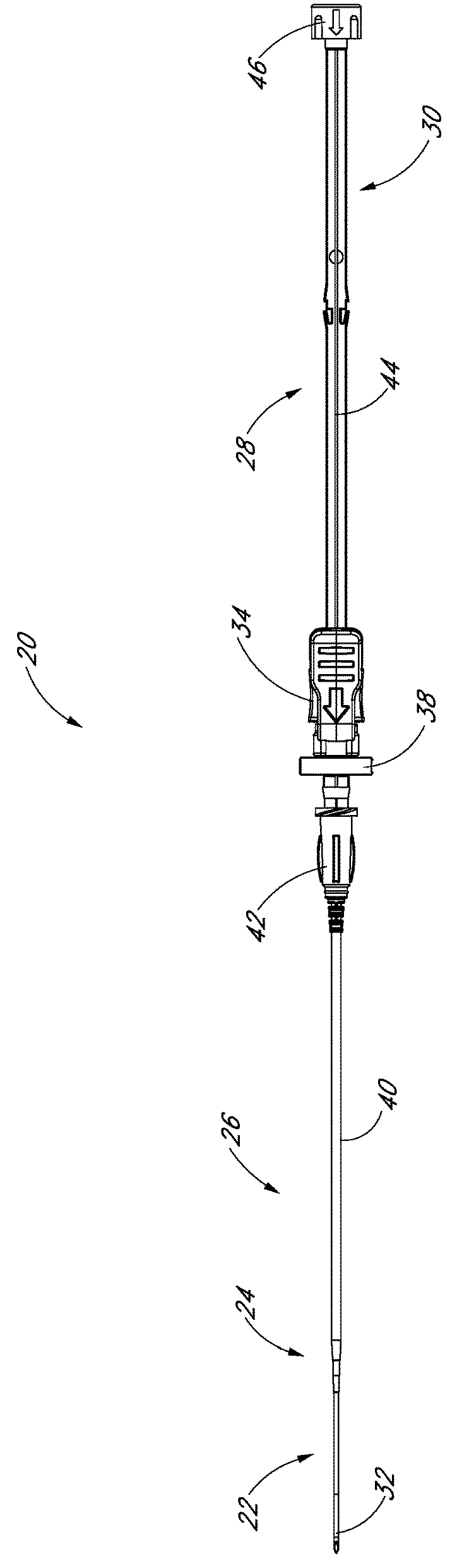

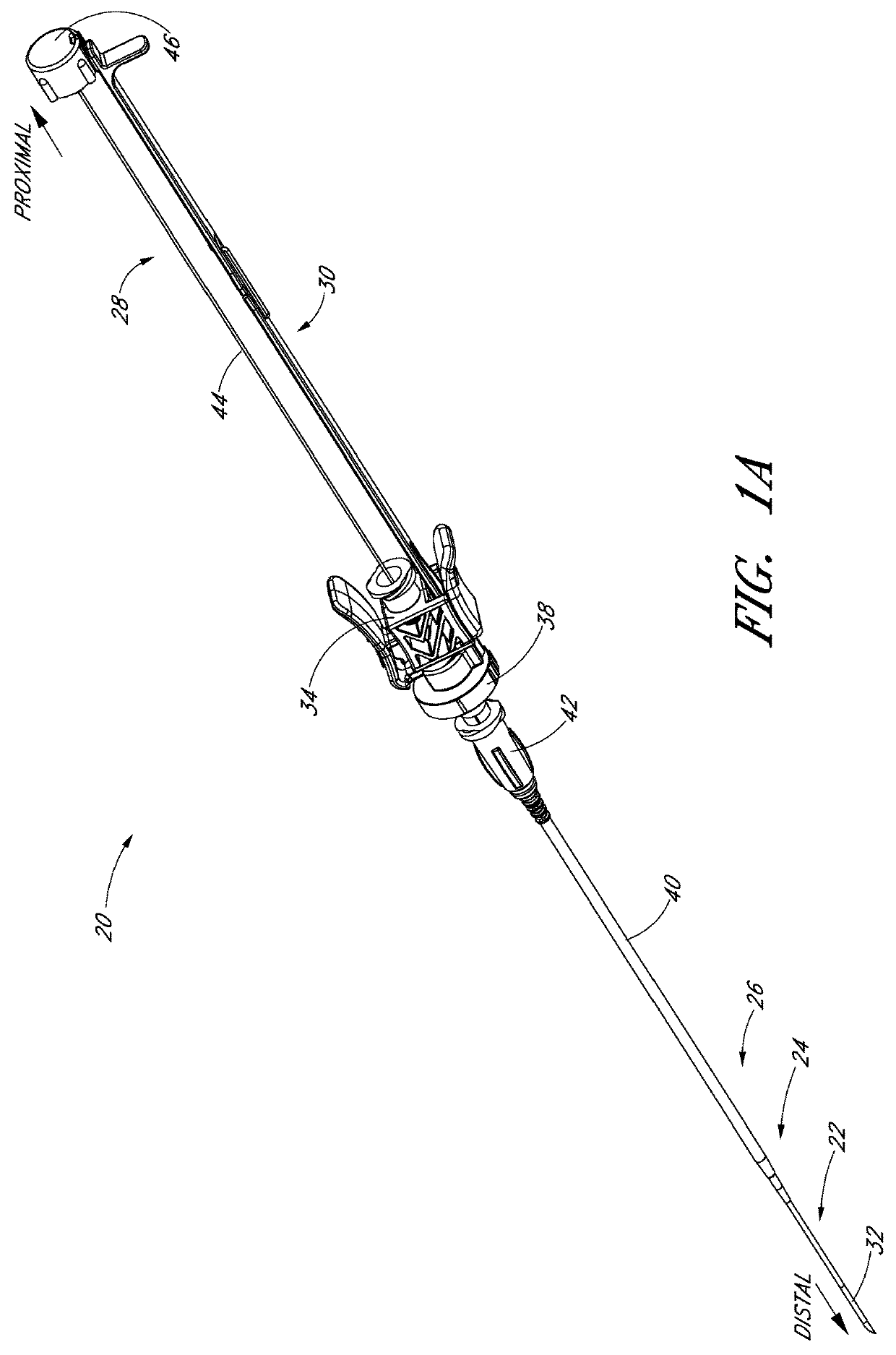

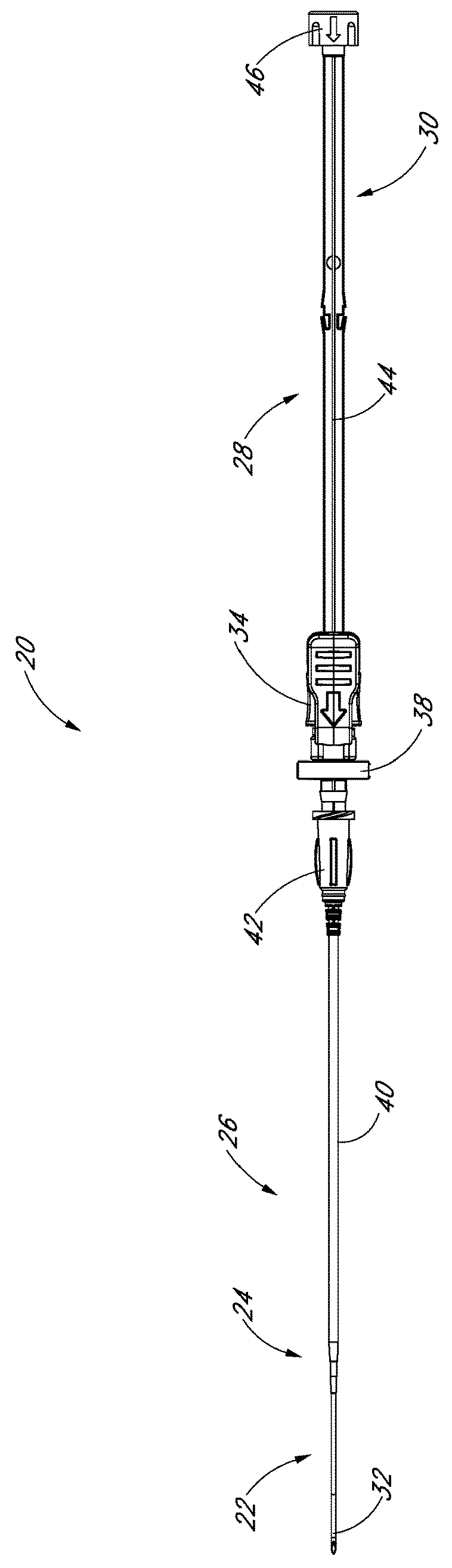

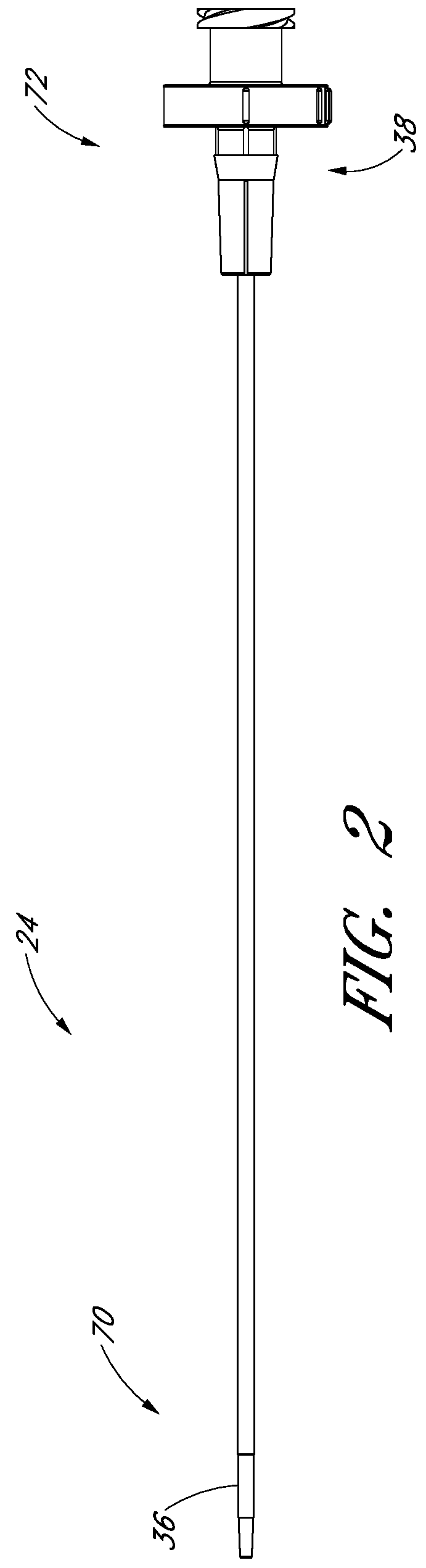

Flexible medical article and method of making the same

ActiveUS9981113B2Increase flexibilityEnhance resilienceGuide needlesDomestic articlesVascular Access DevicesPolycarbonate

A method of making a flexible medical article or tube, for example, a sheath for a vascular access device, is provided. The method can include extruding a polymer, for example, a polycarbonate-urethane copolymer, to form a tube and annealing the extruded polymer. The method can further include cutting the extruded tube to a desired length before or after annealing, flaring one end of the annealed tube and over-molding the flared portion onto a hub, and forming the other end of the tube into a tip. A sheath formed by such a method is also provided.

Owner:SMITHS MEDICAL ASD INC

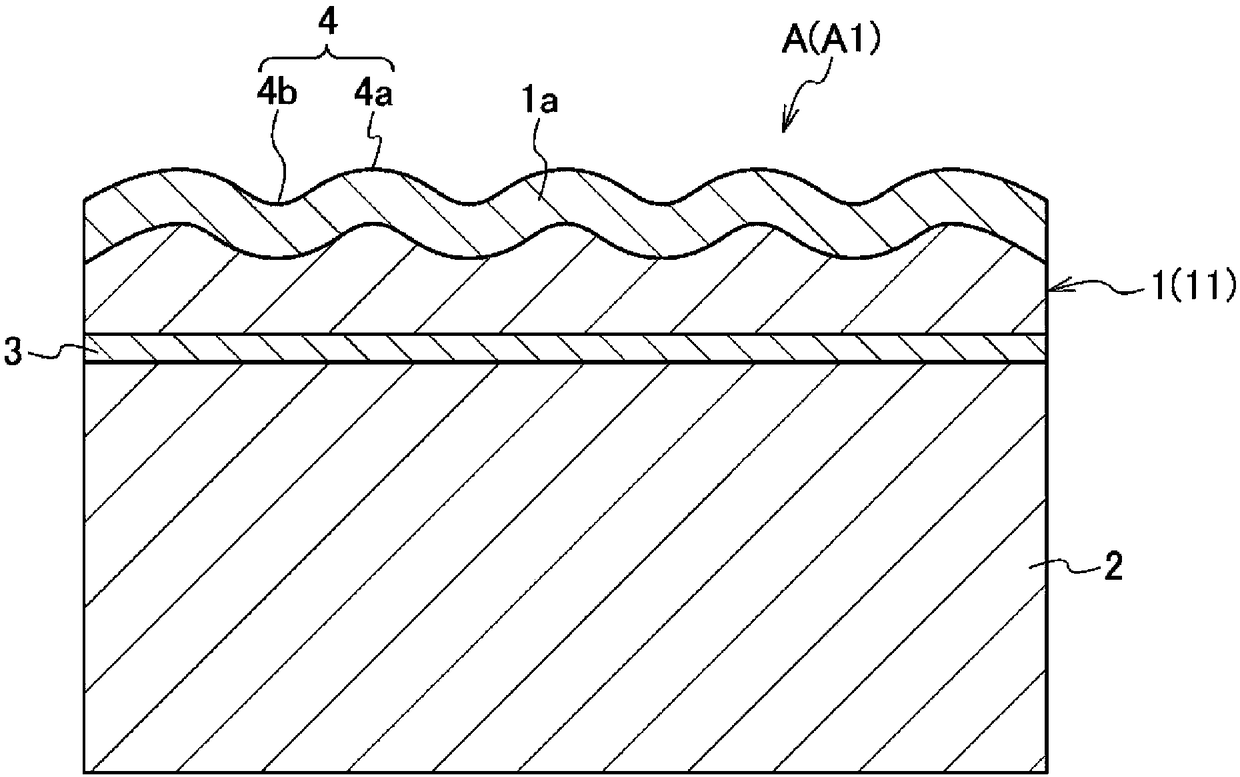

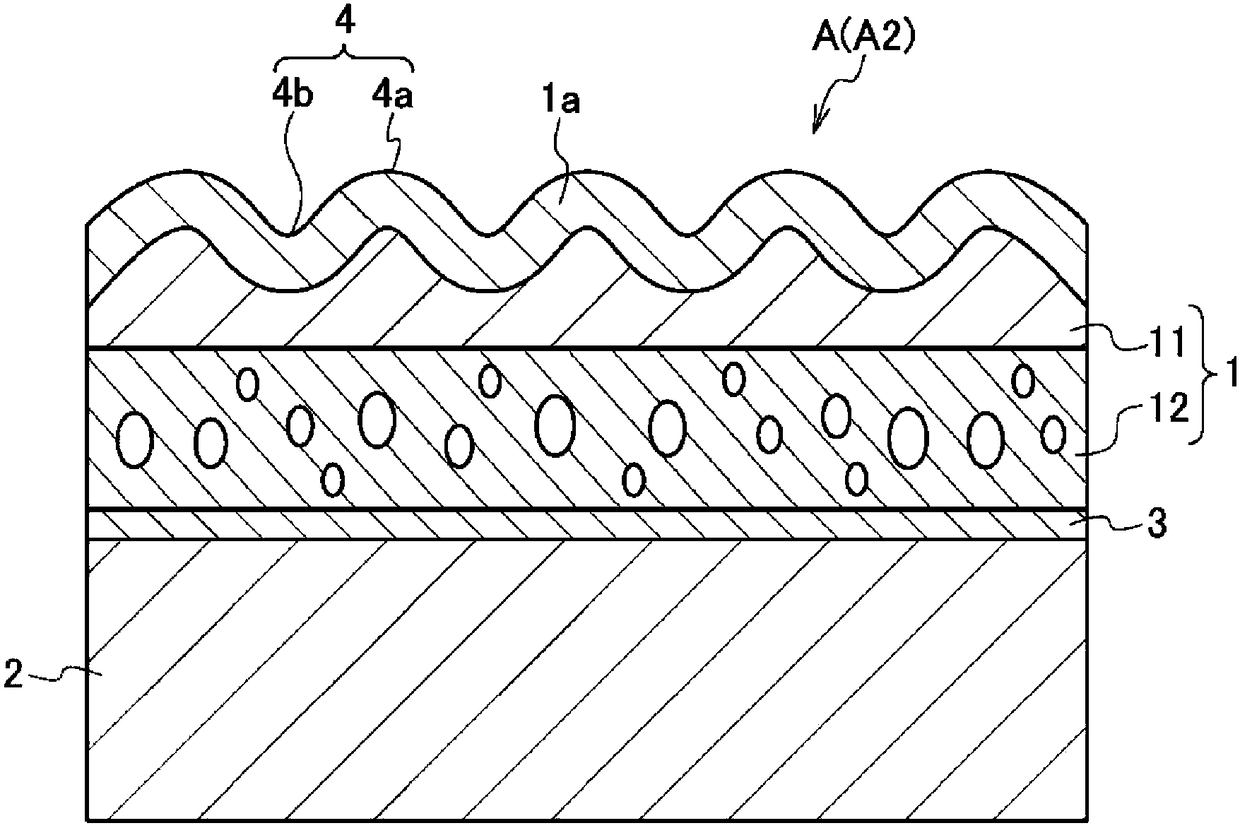

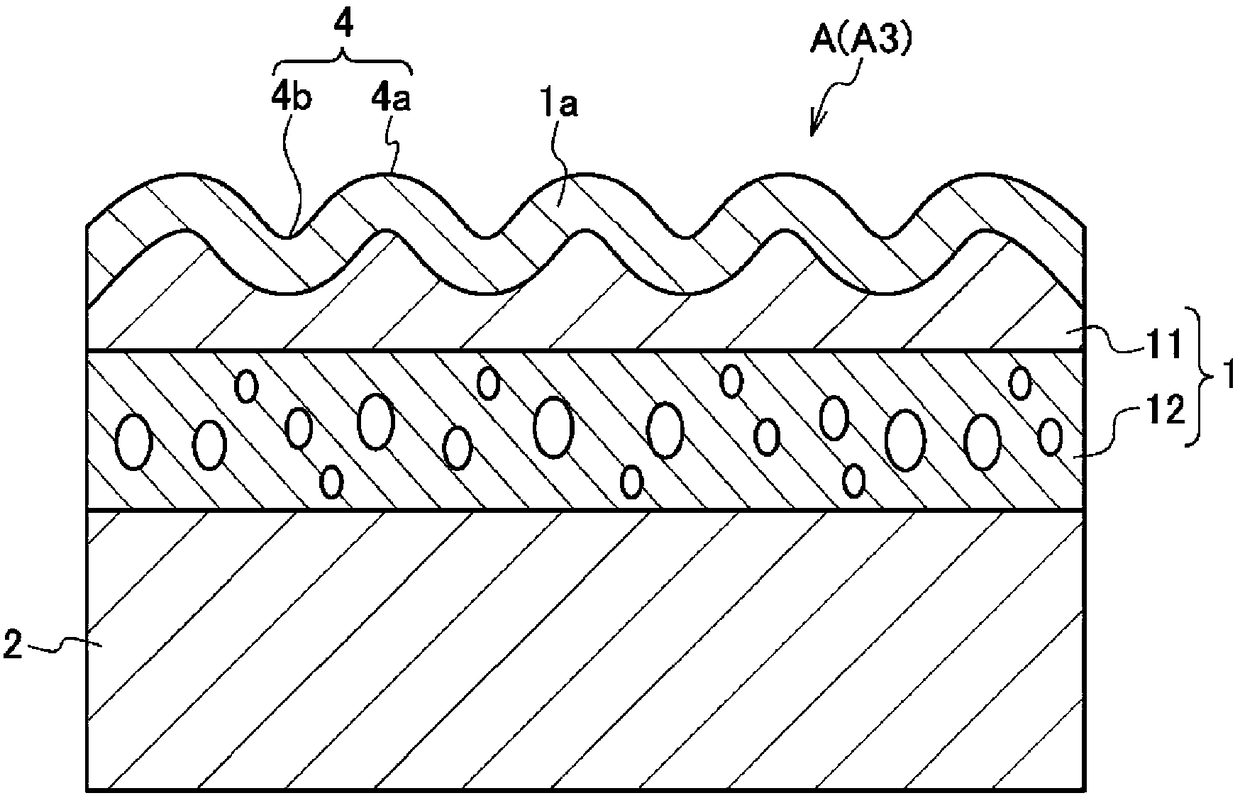

Synthetic resin leather and method for producing same

Provided is a synthetic resin leather having high flexibility and good strength, and abrasion resistance with respect to being repeatedly subjected to rubbing and chemical resistance with respect to human contact. A surface treatment agent obtained by carbodiimide crosslinking of a mixture of polycarbonate urethane and ester urethane is applied to a surface side of film (1), the main component ofwhich is a vinyl chloride resin, and as a result thereof, a surface treatment layer (1a) having excellent flexibility, abrasion resistance, and oleic acid resistance is formed.

Owner:HONDA MOTOR CO LTD +1

Flexible medical article and method of making the same

ActiveUS20180264235A1Increase flexibilityEnhance resilienceGuide needlesDilatorsVascular Access DevicesPolycarbonate

A method of making a flexible medical article or tube, for example, a sheath for a vascular access device, is provided. The method can include extruding a polymer, for example, a polycarbonate-urethane copolymer, to form a tube and annealing the extruded polymer. The method can further include cutting the extruded tube to a desired length before or after annealing, flaring one end of the annealed tube and over-molding the flared portion onto a hub, and forming the other end of the tube into a tip. A sheath formed by such a method is also provided.

Owner:SMITHS MEDICAL ASD INC

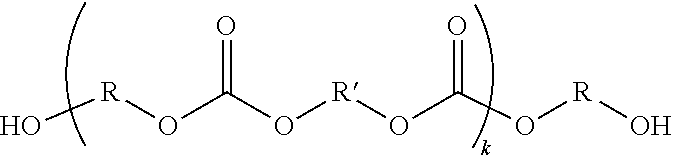

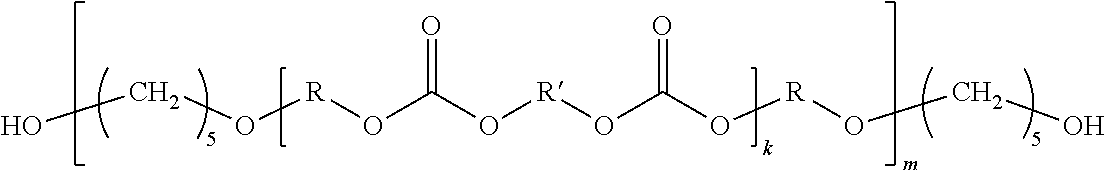

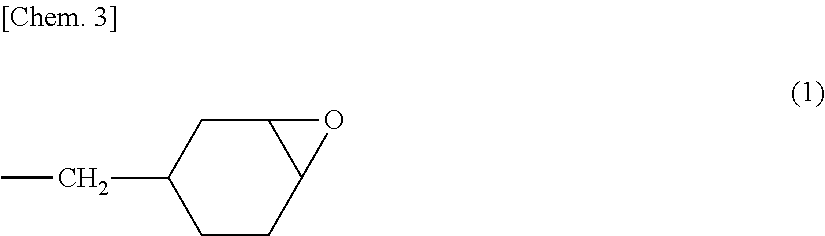

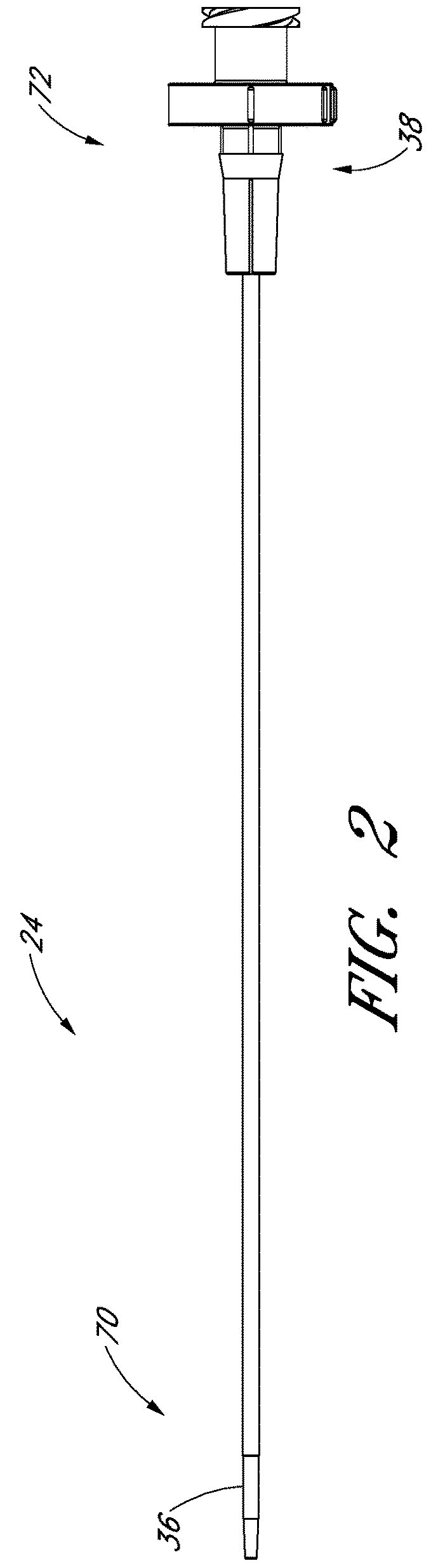

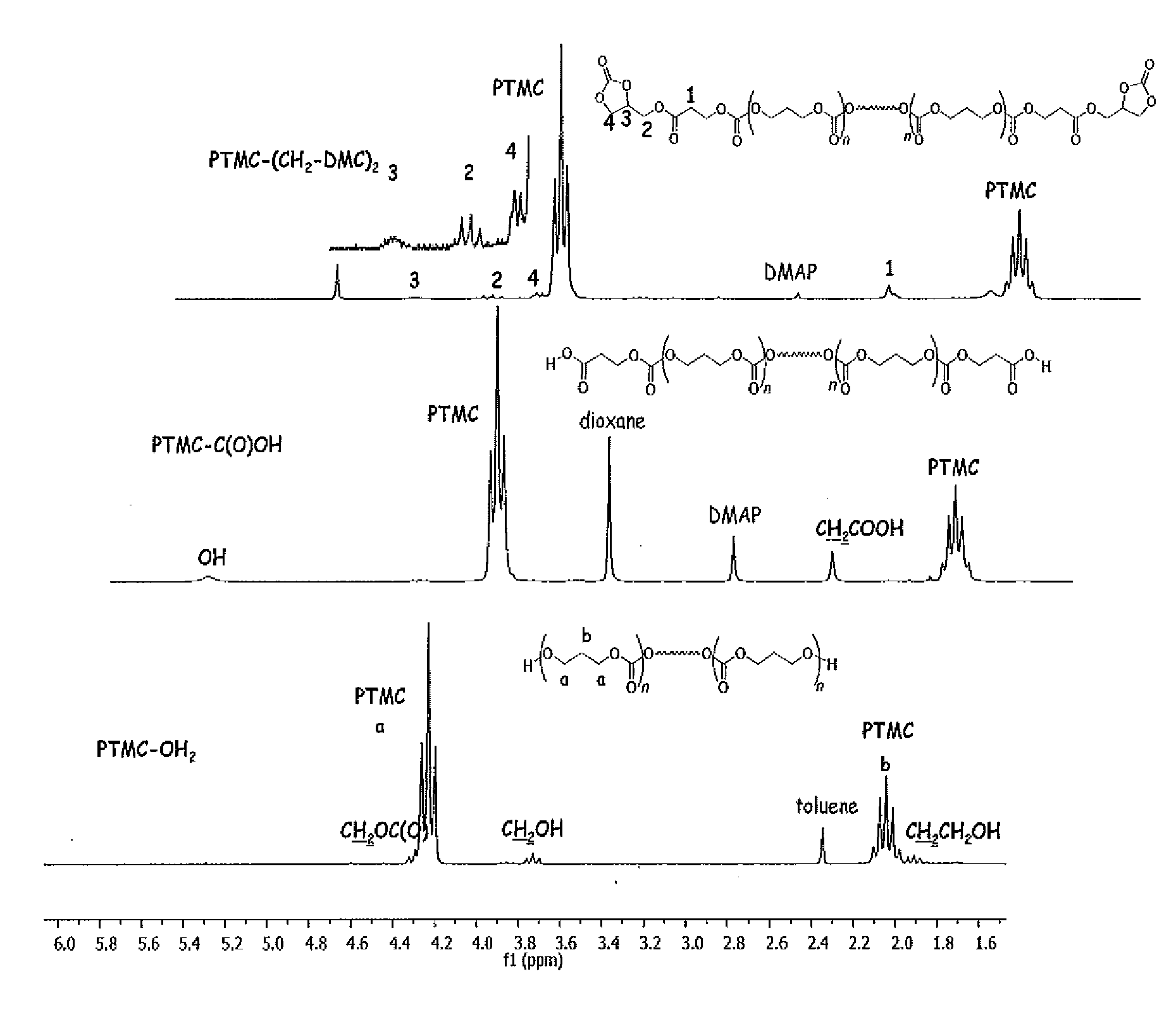

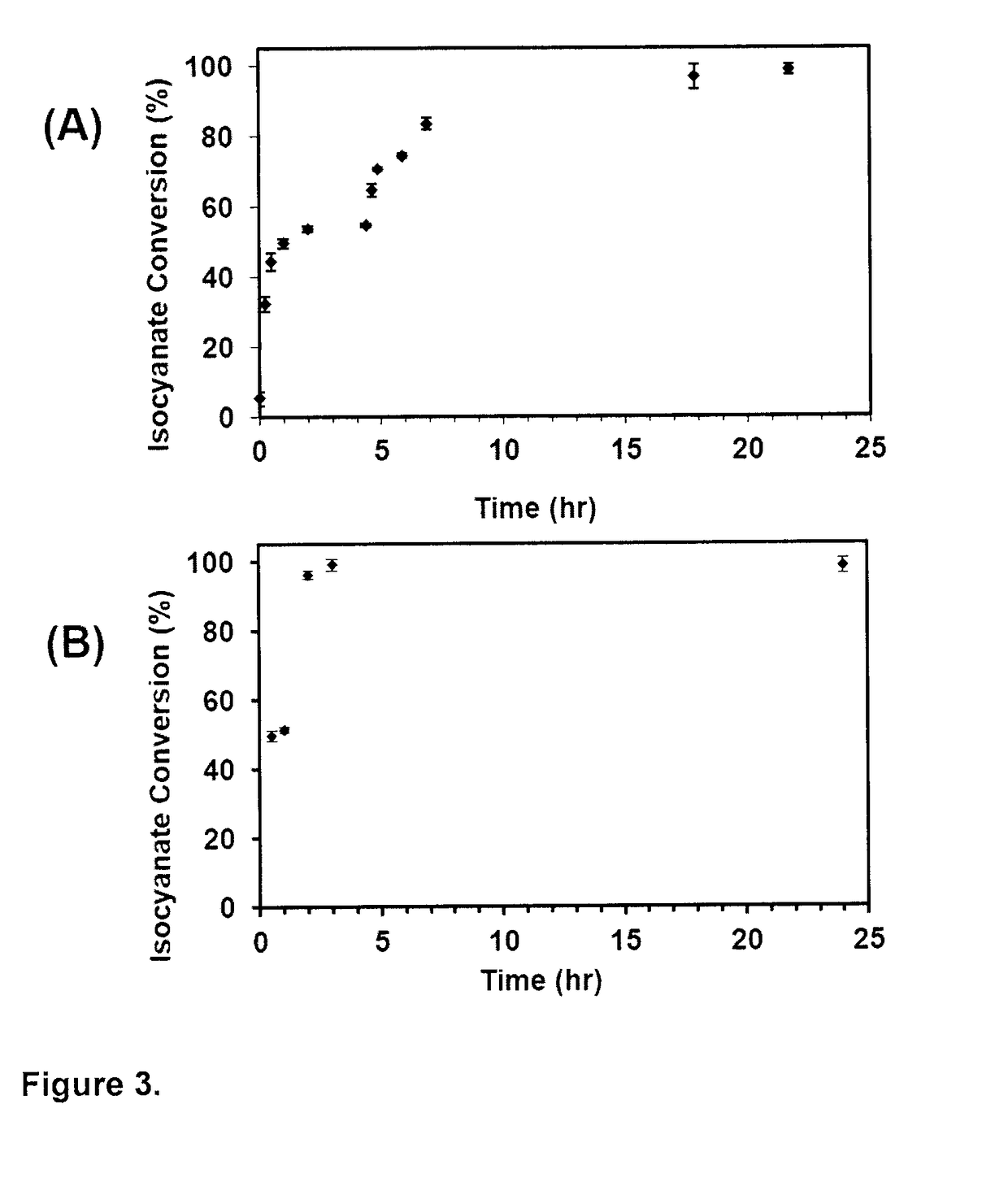

Isocyanate-free method for preparing poly(carbonate-urethane) or poly(ester-urethane)

The present invention discloses a method for preparing polycarbonate-urethane) or poly(ester-urethane) without isocyanate

Owner:TOTAL RES & TECH FELUY +1

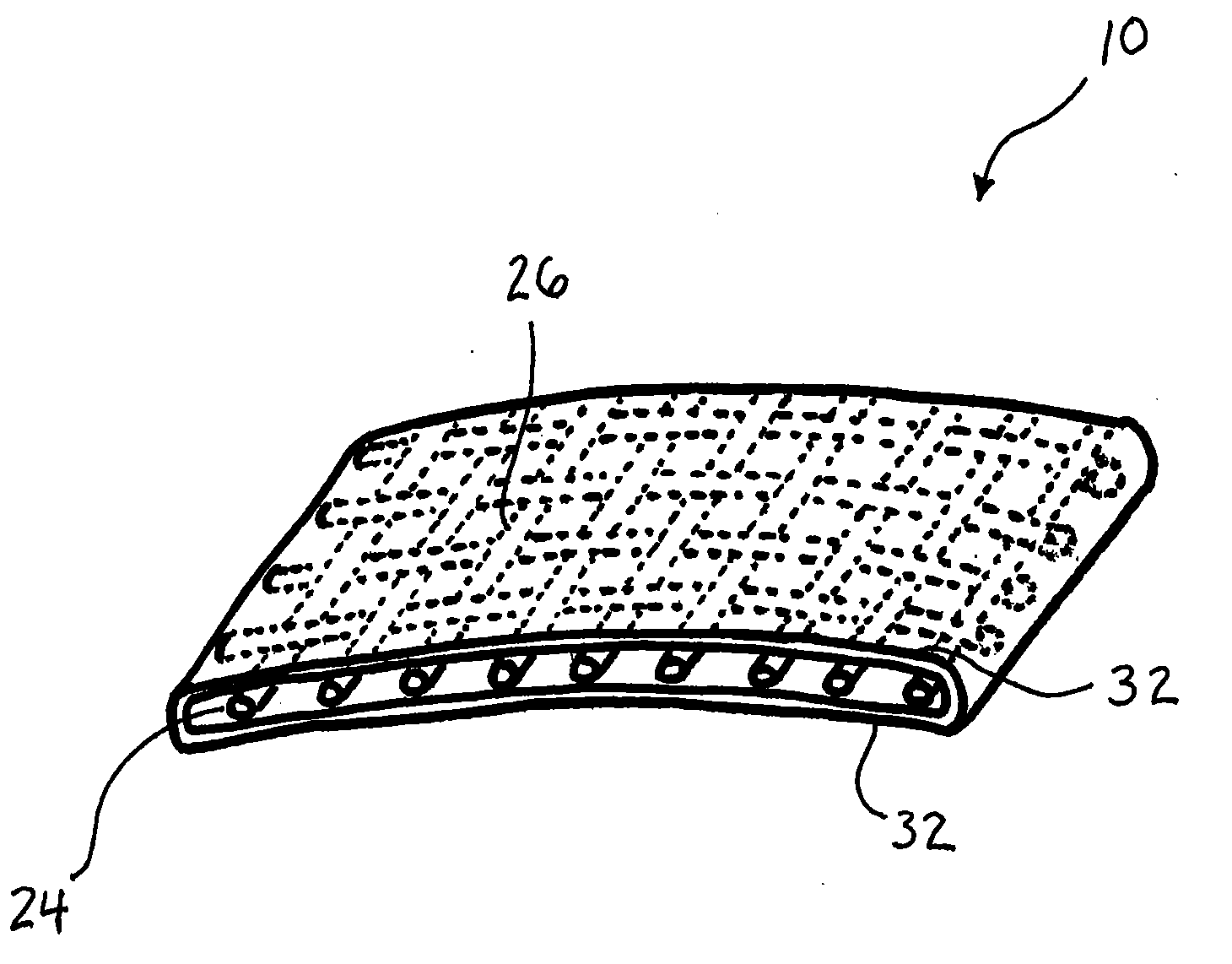

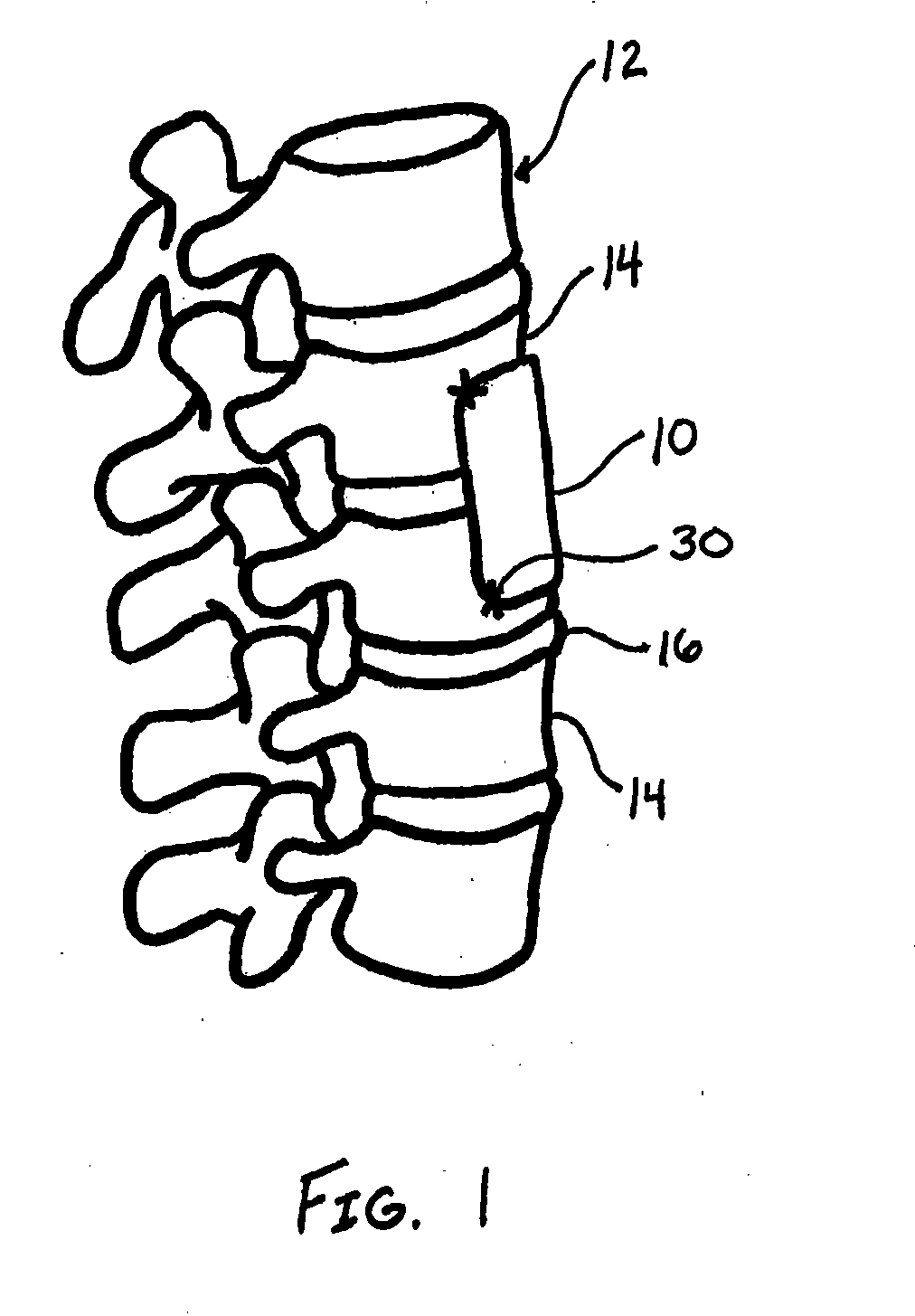

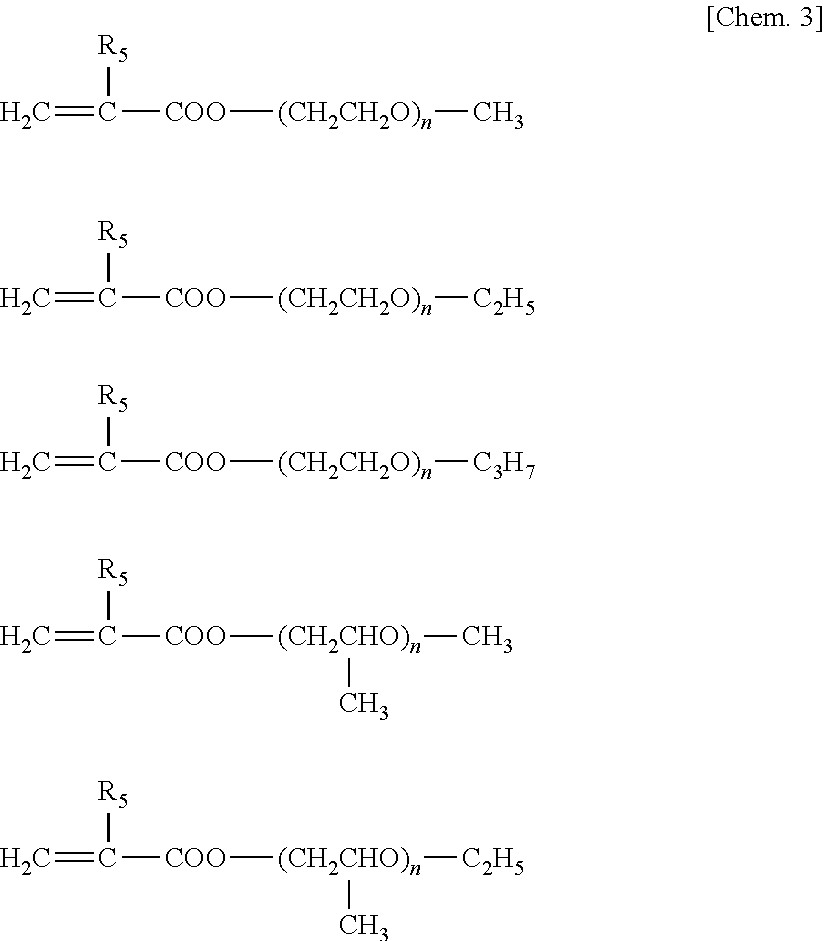

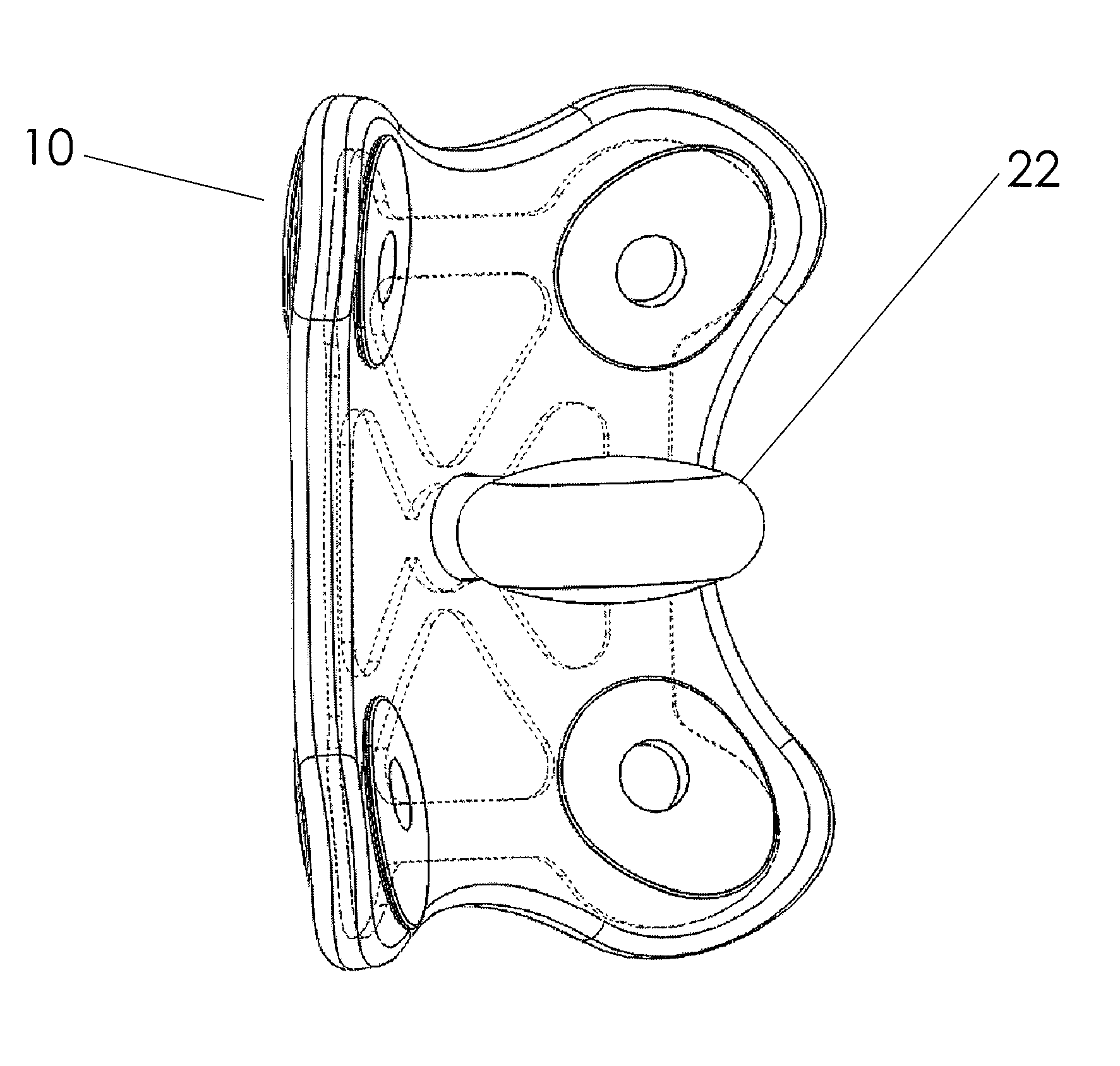

Anterior cervical disc replacement

Disclosed is a cervical plate having a polyester staple fiber laminated within a polycarbonate urethane. The polyurethane provides a flexible, high resilience structure with a Dacron® material providing a flexible skeleton. The result is a cervical plate that is flexible but provides the necessary rigidity. An inflatable balloon can be used to mimic the properties of the natural disc by maintaining the intervertebral disc space through a full range of natural motion.

Owner:ATLAS SPINE

Flexible medical article and method of making the same

ActiveUS20180264234A1Reduce stiffnessIncrease flexibilityGuide needlesDilatorsVascular Access DevicesPolycarbonate

Owner:SMITHS MEDICAL ASD INC

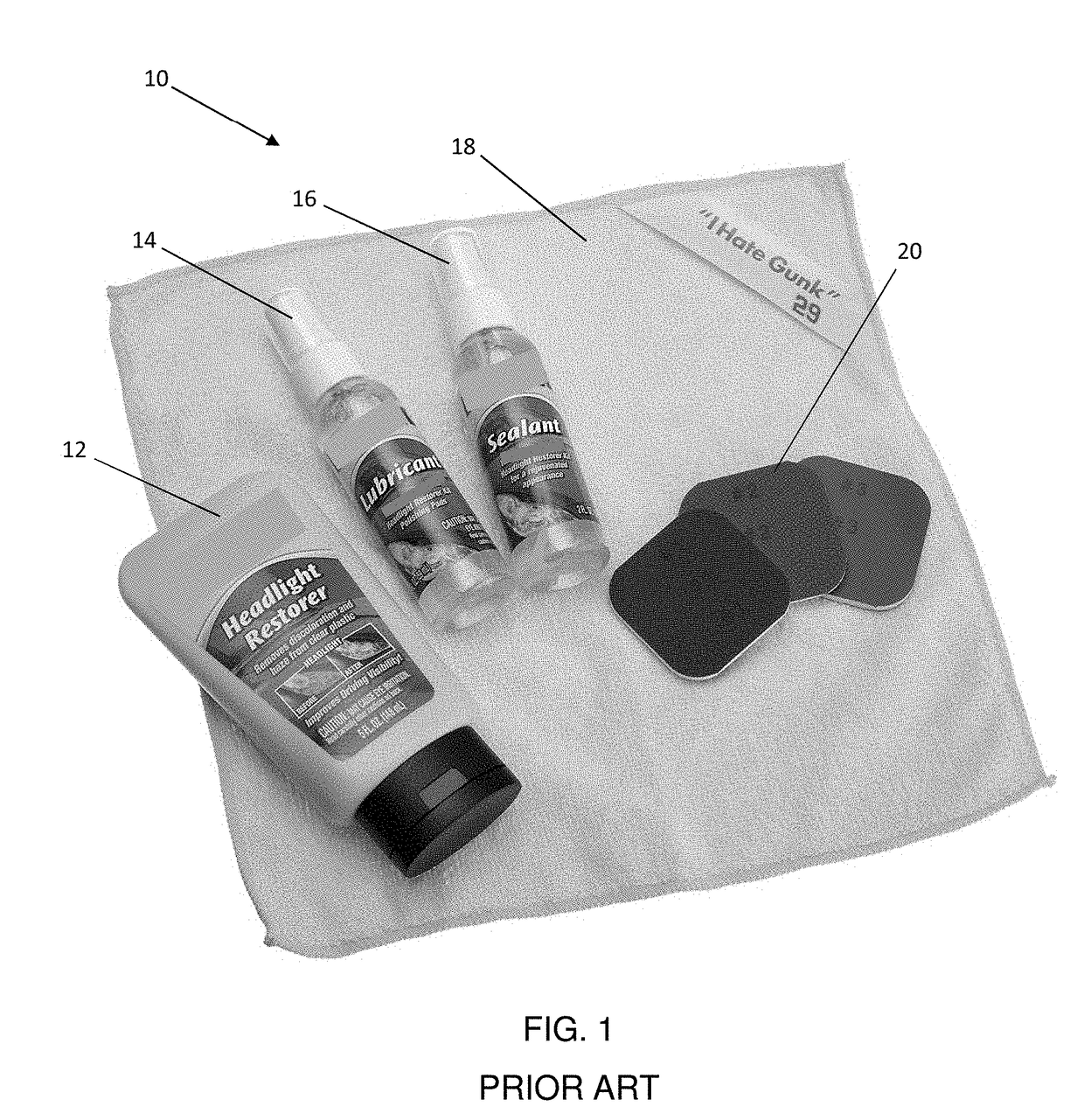

One-step headlight restoration kit and formulation

A one-step headlight restoration formulation is also provided that includes a polyurethane dispersion of aliphatic polycarbonate urethane present from 20 to 85 total weight percent, along with a wetting agent present from 1 to 4 total weight percent. A biocide is present from 0.005 to 0.5 total weight percent of the formulation. A carrier constitutes the remainder of the formulation. A kit for a one-step headlight restoration is provided that includes a wipe for applying said formulation to a headlight surface in need of resurfacing as a one step process. The process of using the kit includes removing a formulation impregnated wipe from an envelope and contacting the wipe with the headlight surface to apply said formulation by wiping evenly on a headlight lens surface to form a restorative film.

Owner:ILLINOIS TOOL WORKS INC

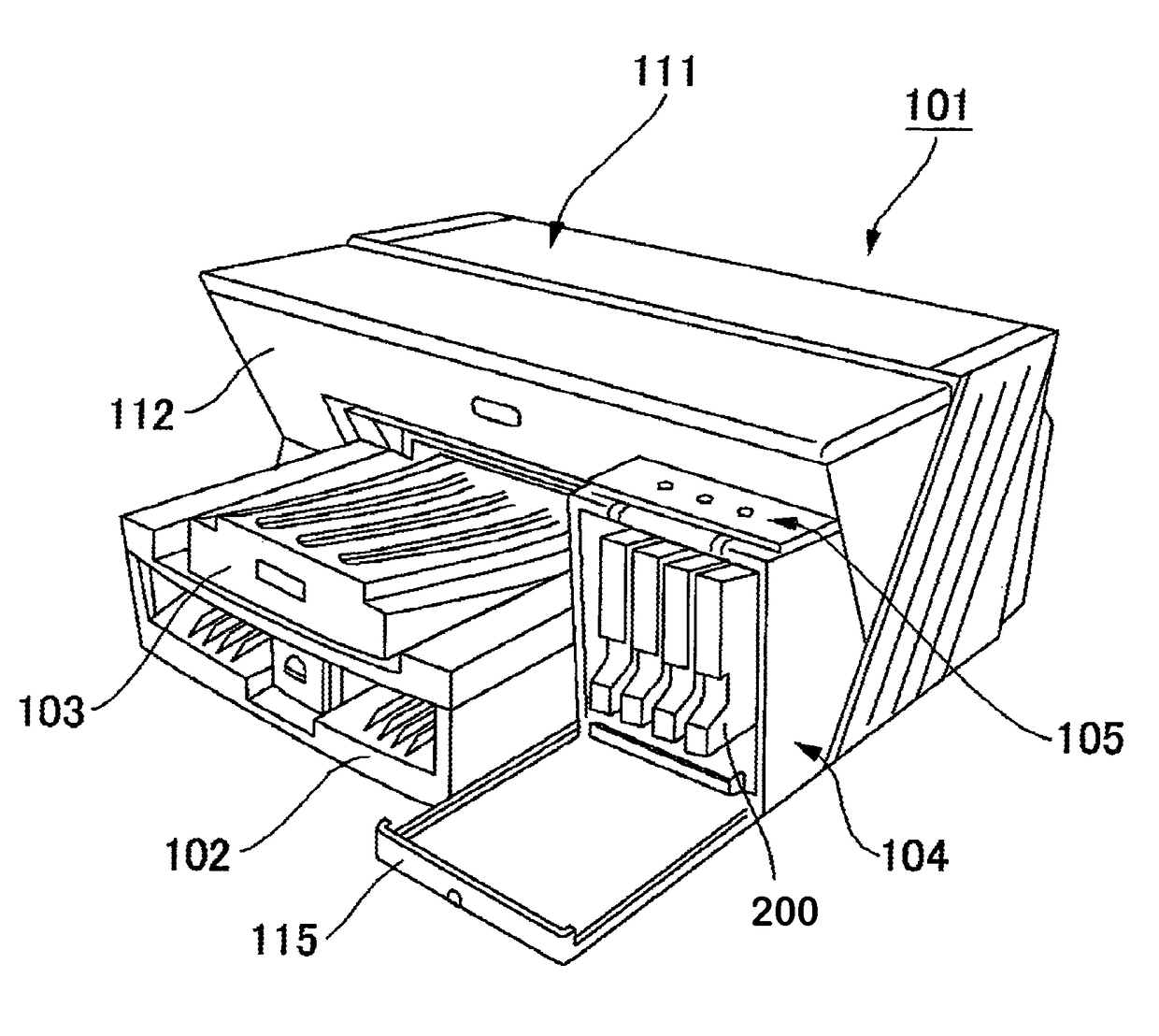

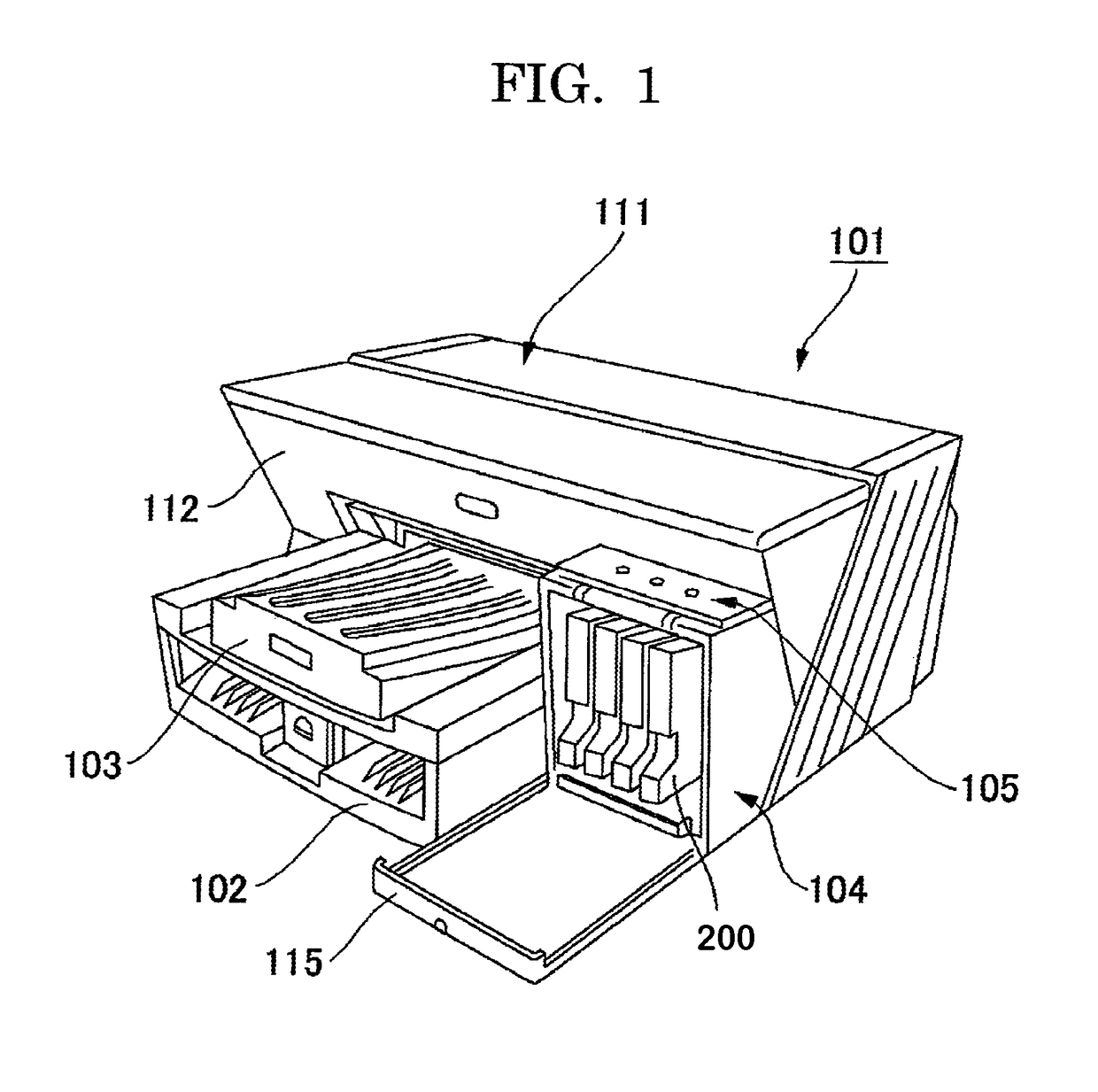

Inkjet ink, inkjet recording method and ink recorded matter

An inkjet ink, containing: water; a water-soluble organic solvent; a pigment; and polycarbonate urethane resin particles, wherein the water-soluble organic solvent contains 50% by mass or more of a diol compound, and wherein the water-soluble organic solvent contains 50% by mass or more of a water-soluble organic solvent having a boiling point of 200° C. or less.

Owner:RICOH KK +1

White ink, ink set, and recording method

ActiveUS20210363367A1High whitenessHardly generates crackInksDyeing processPolymer sciencePolyether polyurethane

A white ink containing a white pigment, a polycarbonate urethane resin, a polyether urethane resin, and water; and a recording method using the white ink. An ink set provided with the white ink and at least one color ink, the color ink being an aqueous ink containing a coloring agent, the white ink and the color ink differing in surface tension at 25° C. by ±0-3 mN / m; and a recording method using the ink set.

Owner:NIPPON KAYAKU CO LTD

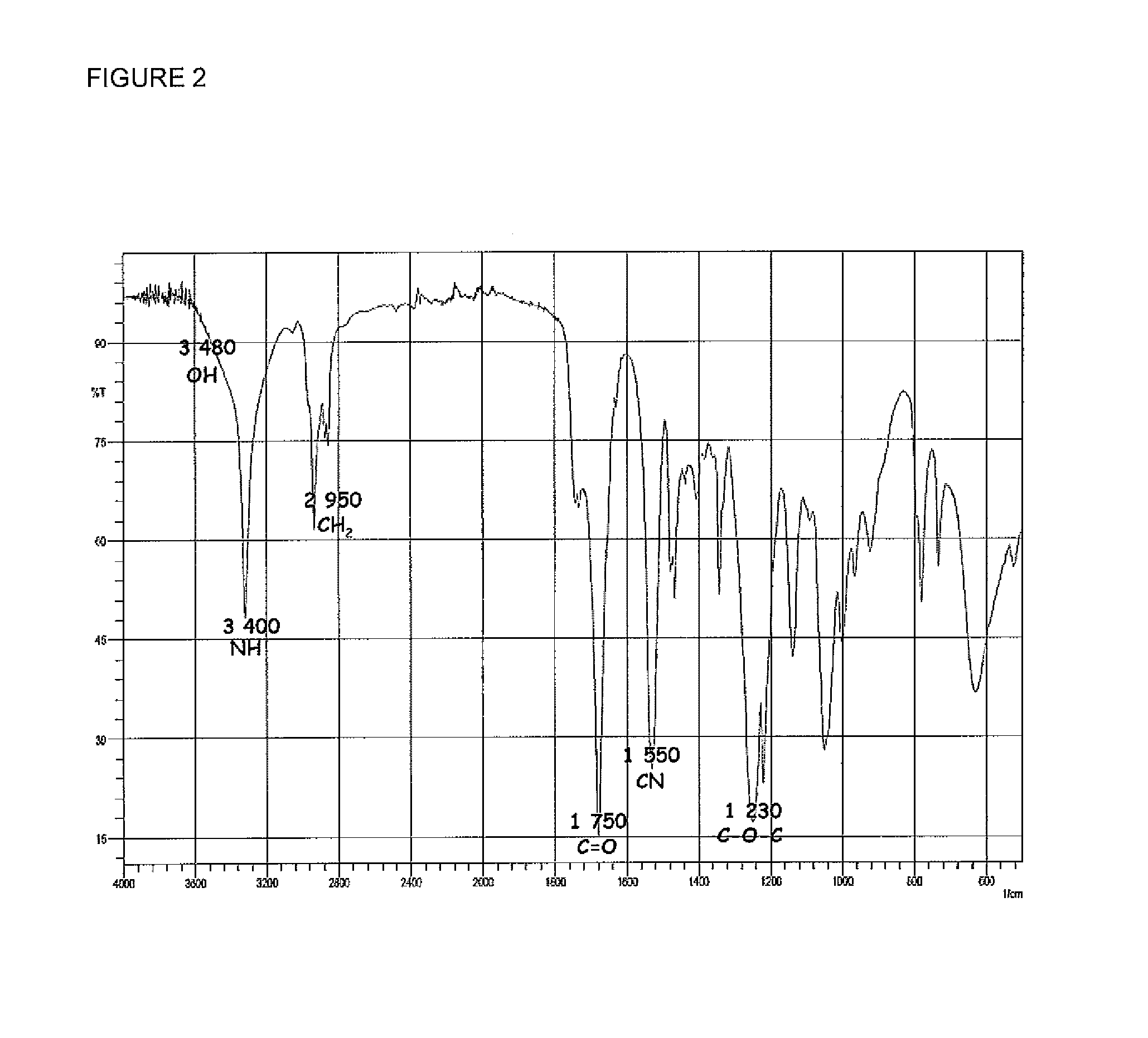

Non-woven fabric for medical use and process for the preparation thereof

Process for preparing a non-woven fabric for medical use, comprising the following steps: -performing a spraying process in which -a spray jet is generated from a polycarbonate urethane plastic solution having a viscosity of from 800 to 1500 Pa.s using a spraying unit from which the polycarbonate urethane plastic solution exits; -said spray jet includes at least one strand of a single microfiber that may have a diameter of from 1 to 15 [mu]m, preferably a diameter of from 2 to 10 [mu]m; -said at least one strand of the single microfiber is sprayed onto a support, wherein -the support is moved relative to the spraying unit, or the spraying unit is moved relative to the support; -the spraying process is repeated several times to form polycarbonate urethane microfiber layers; -whereby polycarbonate urethane microfibers formed from the individual spraying processes overlay each other and adhere to each other at the respective contact points; and -a non-woven fabric having a fibrillar microporous structure is formed; -and optionally detached from the support after the last spraying process.

Owner:无纺技术医学有限公司

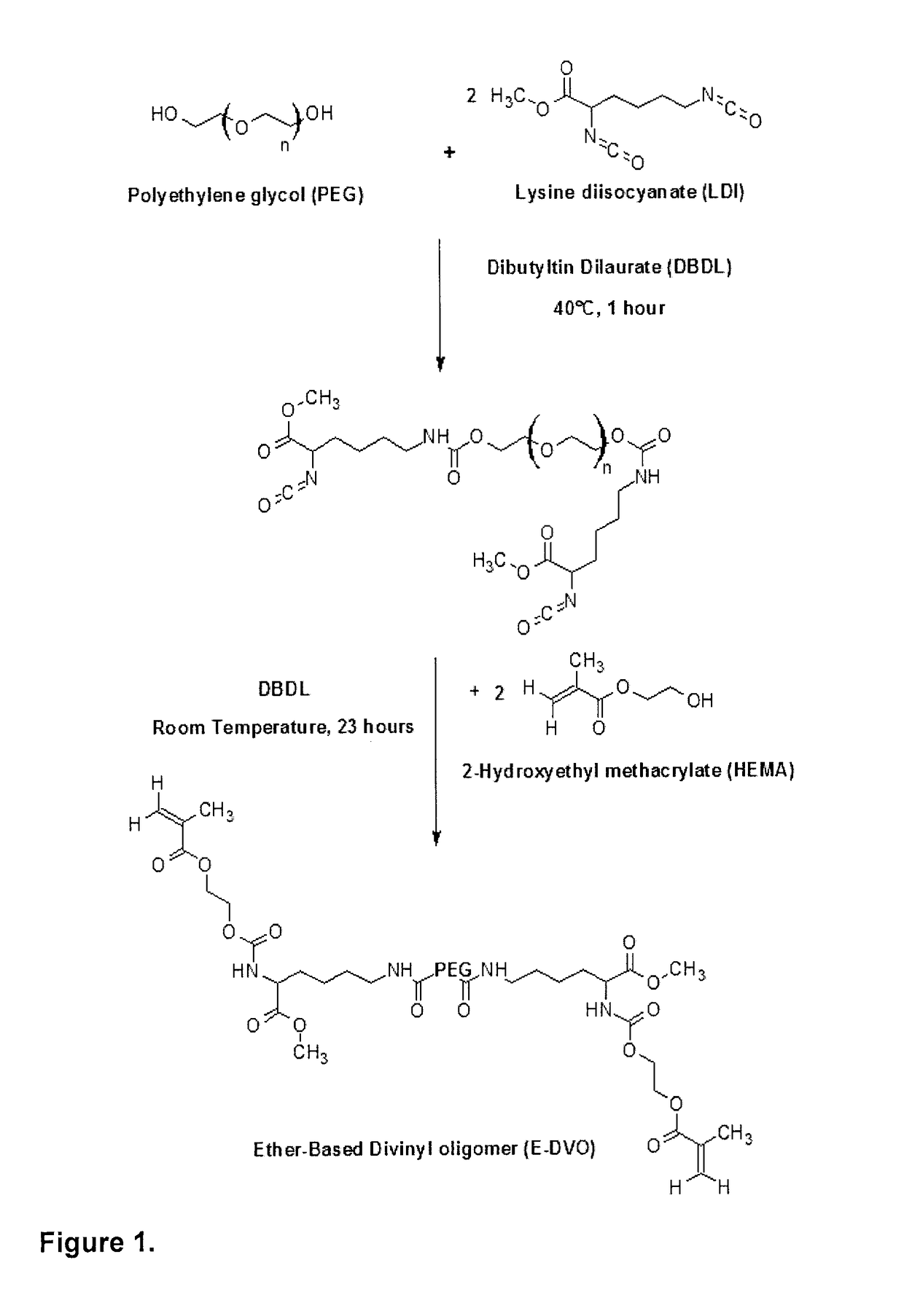

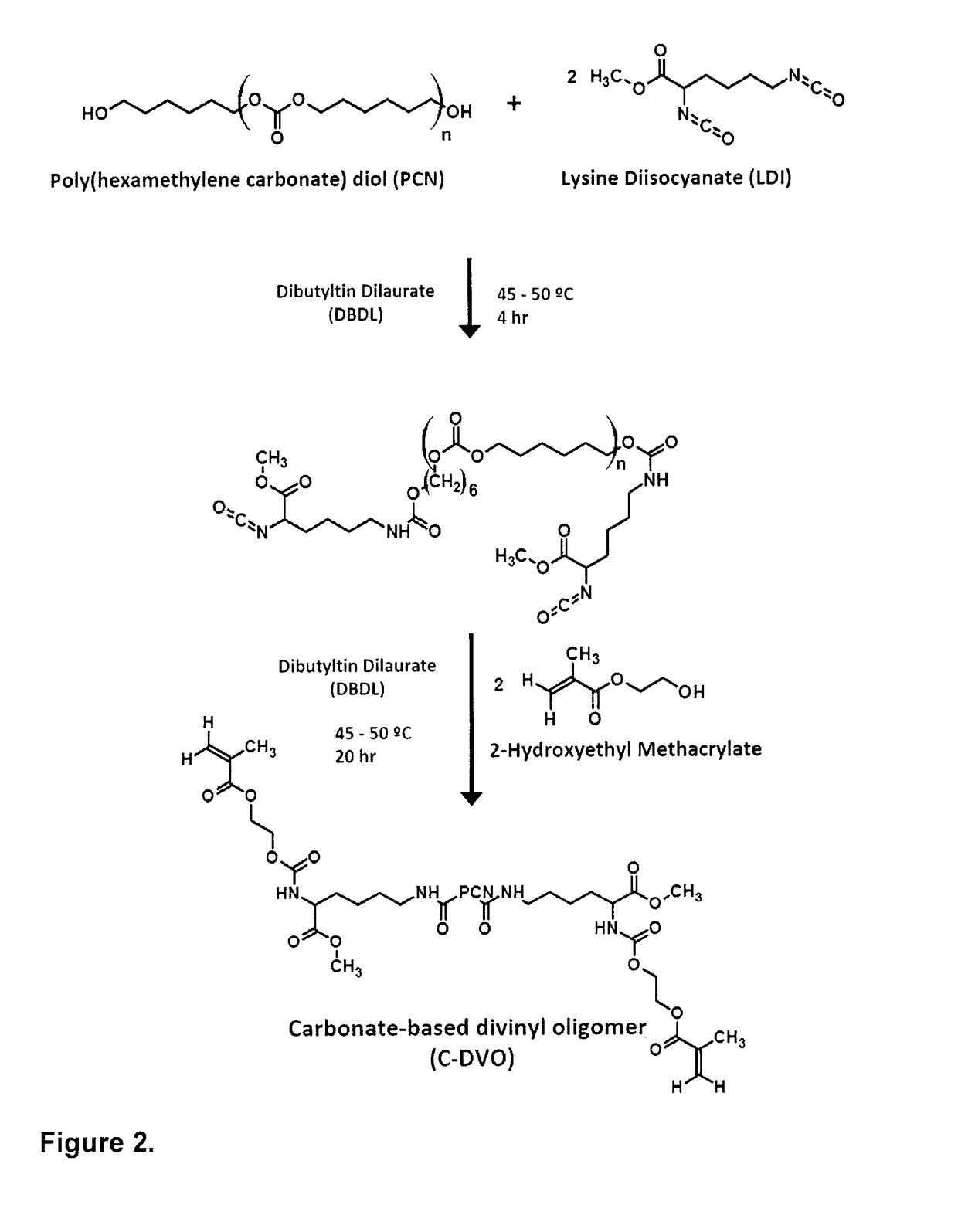

Soft tissue filler

A soft tissue filler comprising a biodegradable amino-acid derived polycarbonate-urethanes and methods of repairing soft tissue defects are provided. The biodegradable soft tissue filler comprises a porous scaffold that is the reaction product of: a) a divinyl oligomer component that comprises a carbonate-derived divinyl oligomer that is the reaction product of a lysine-derived diisocyanate, a vinyl coupling agent, and a polycarbonate and, optionally, an ether-derived divinyl oligomer, wherein the ether-derived divinyl oligomer is the reaction product of a lysine-derived diisocyanate, a vinyl coupling agent, and an ether; b) at least one anionic monomer; and c) at least one hydrophobic monomer. The molar ratio of (a):(b+c) is between about 1:≥21 and about 1:30, the soft tissue filler has a porosity of >75%; and a compressive moduli of between about 1 kPa and about 50 kPa.

Owner:THE GOVERNINIG COUNCIL OF THE UNIV OF TORANTO +1

Anterior cervical disc replacement

Disclosed is a cervical plate having a polyester staple fiber laminated within a polycarbonate urethane. The polyurethane provides a flexible, high resilience structure with a Dacron® material providing a flexible skeleton. The result is a cervical plate that is flexible but provides the necessary rigidity. An inflatable balloon can be used to mimic the properties of the natural disc by maintaining the intervertebral disc space through a full range of natural motion.

Owner:ATLAS SPINE

A kind of preparation method of polyurethane adhesive for protective film

ActiveCN104558503BImprove hydrolysis resistanceGood flexibilityFilm/foil adhesivesPolyureas/polyurethane adhesivesTectorial membranePolyurethane adhesive

The invention discloses a preparation method for a polyurethane adhesive applied to a protective film. The preparation method specifically comprises the following steps: dissolving polyether polyol and hexamethylene diisocyanate in methylbenzene for prepolymerization under the condition of using organic tin as a catalyst; after the prepolymerization is completed, adding a mixture of polycarbonate polyol and methylbenzene for chain extension reaction to obtain colorless transparent polyurethane adhesive main agent. The prepared polyurethane adhesive applied to the protective film has the the advantages of both polyether urethane and polycarbonate urethane, such as outstanding hydrolysis resistance and excellent balance between flexibility and rigidity; the protective film with the polyurethane adhesive has the advantages of low viscosity, excellent exhaust performance, rime fog resistance and the like; furthermore, the preparation conditions of the adhesive are mild, and the preparation of the adhesive does not need special devices and only needs the traditional stirring and hydrothermal conditions; industrial production is facilitated.

Owner:CYBRID TECHNOLOGIES INC

Battery separator and battery using the same

InactiveUS9142818B2Improve antioxidant capacityAdhesivenessCell seperators/membranes/diaphragms/spacersFinal product manufacturePorous substrateHydrogen

The present invention relates to a battery separator including: a porous substrate; and a layer of a crosslinked polymer supported on at least one surface of the porous substrate, in which the crosslinked polymer is obtained by reacting (a) a reactive polymer having, in the molecule thereof, a reactive group containing active hydrogen with (b) a polycarbonate urethane prepolymer terminated by an isocyanate group.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com