Synthetic resin leather and method for producing same

A technology of synthetic resin and leather, applied in the field of synthetic resin leather and its manufacture, can solve the problem of not being able to obtain sufficient abrasion resistance or chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12 and comparative example 1~8

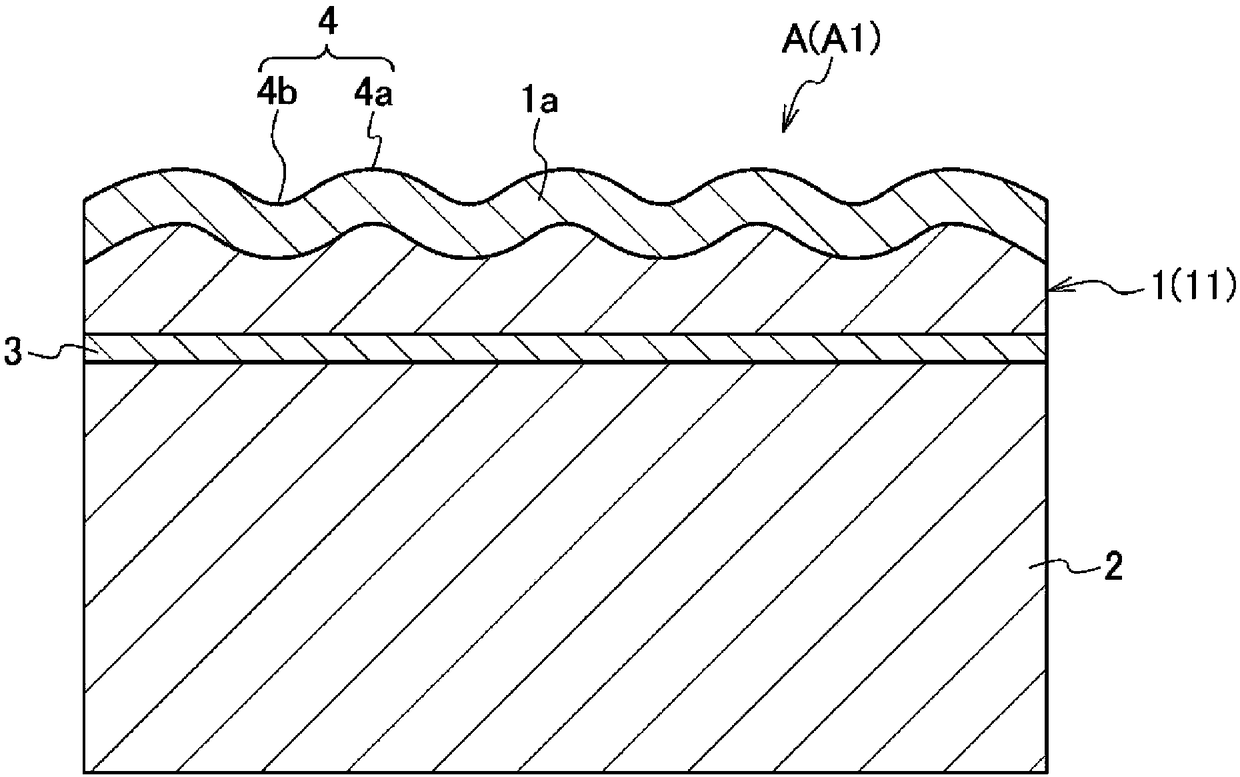

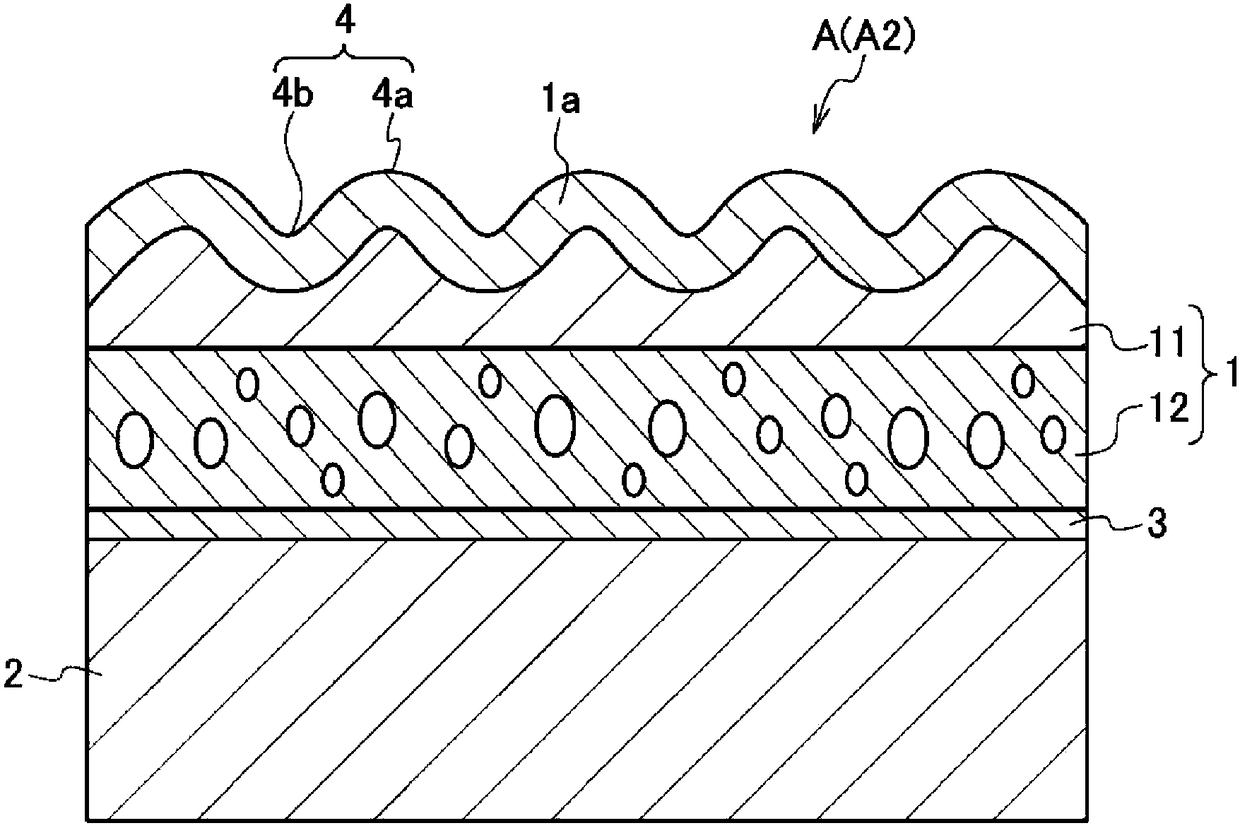

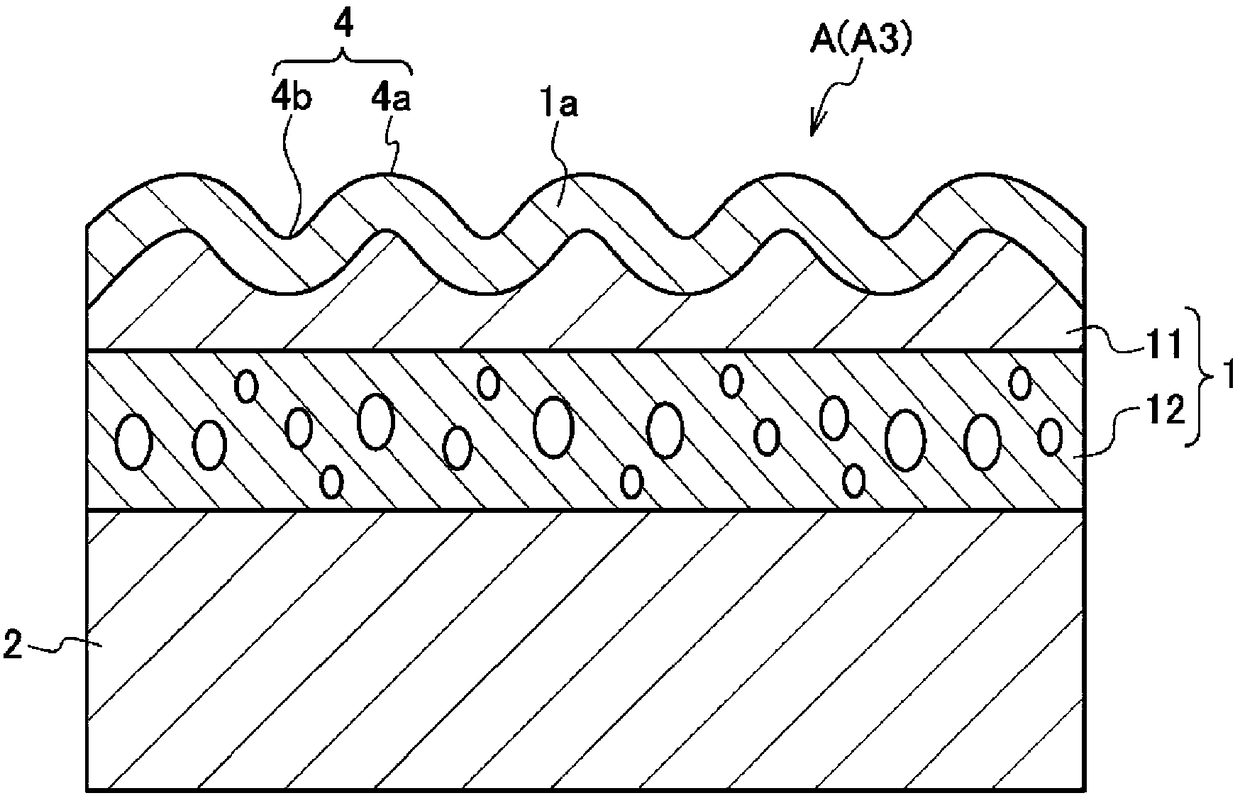

[0111] The components described in Examples 1 to 12 shown in Table 1 and Comparative Examples 1 to 8 shown in Table 2 were blended in their respective ratios, and molded into a non-foamed layer with a thickness of 0.3 mm by calender molding 11 and a foam layer 12 with a thickness of 0.6mm. The non-foamed layer 11 and the foamed layer 12 are overlapped with the base material 2 (a two-component polyurethane adhesive is applied to a plush knitted fabric woven with 100% polyester 83T crimped silk), heated and heated. After making it foam, it is pressed with a squeeze roll and a rubber roll, so that the foam layer 12 is bonded to the base material 2 while being squeezed to obtain a image 3 Synthetic resin leather A (A3) with a concave-convex pattern 4 is shown.

[0112] Specifically, the non-foaming layer 11 of the film 1 is a plasticizer (diisophthalic acid diiso Decyl ester: DIDP), plasticizer (epoxidized soybean oil), heat stabilizer (barium-zinc mixed stabilizer), filler (ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com