Light wall board and manufacturing technology thereof

A lightweight wallboard and cement technology, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc. The effect of increasing the type and increasing the area of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

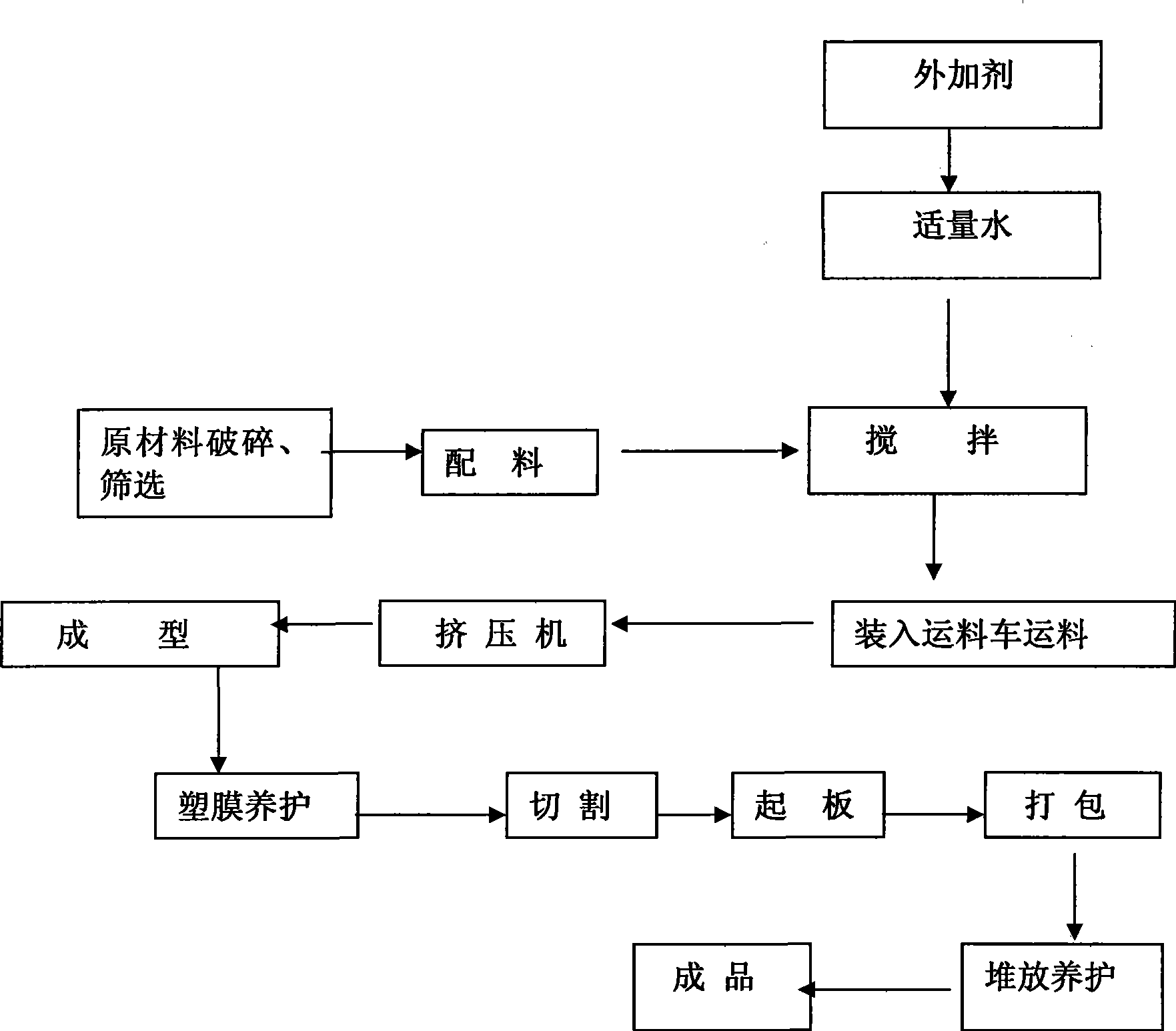

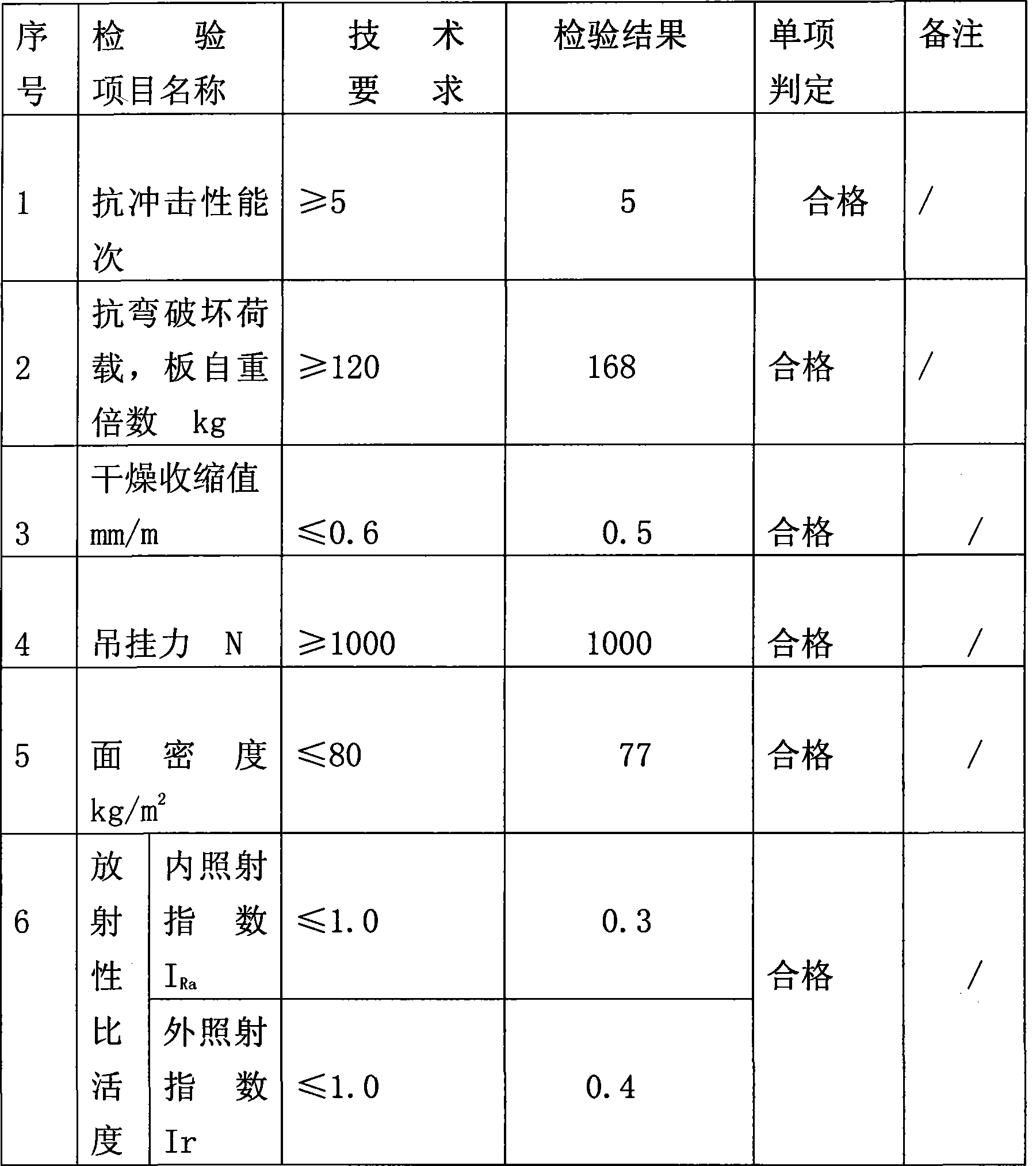

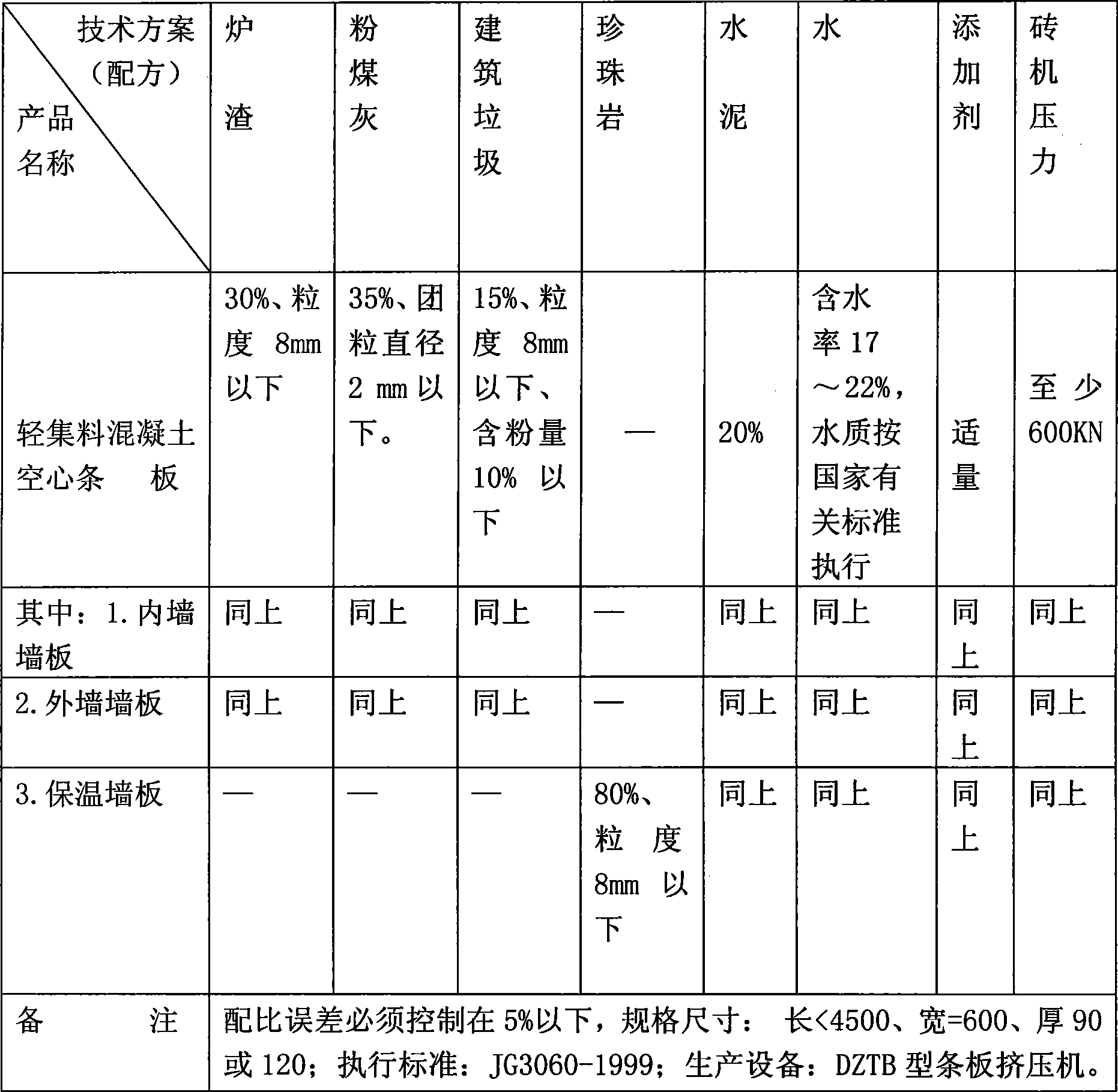

[0127] Production of Light Aggregate Concrete Hollow Slabs

[0128] 1. Crushing and screening of raw materials. The raw materials that do not meet the formula requirements are first crushed and screened. For example, the slag should be crushed to the allowable particle size range in the formula with a pulverizer.

[0129] 2. Ingredients. According to the recipe requirements, after the various raw materials are measured, such as the lifting bucket of the mixer, they are injected into the mixing drum for stirring. And repeat the batching to ensure the continuous work of the mixer. The formula ratio (percentage by weight) is as follows:

[0130] Slag - 30%, particle size below 8mm.

[0131] Fly ash - 35%, aggregate diameter below 2mm.

[0132] Construction waste - 15%, particle size below 8mm, powder content below 10%.

[0133] Cement - 20%. According to the requirements of wall materials for different purposes, rapid hardening sulfoaluminate cement or modified Portland ce...

Embodiment 2

[0146] Inner wall panels: Mainly develop two kinds of industrial waste slag light aggregate wall panels and coal gangue wall panels after spontaneous combustion. The invention can improve the sound insulation performance of the product to ≥42dB and reduce the shrinkage rate to ≤0.05mm / m.

[0147] 1. Crushing and screening of raw materials. The raw materials that do not meet the formula requirements are first crushed and screened. For example, the slag should be crushed to the allowable particle size range in the formula with a pulverizer.

[0148] 2. Ingredients. According to the recipe requirements, after the various raw materials are measured, such as the lifting bucket of the mixer, they are injected into the mixing drum for stirring. And repeat the batching to ensure the continuous work of the mixer. The formula ratio (percentage by weight) is as follows:

[0149] Industrial waste - 40%, particle size below 8mm.

[0150] Coal gangue after spontaneous combustion - 40%,...

Embodiment 3

[0164] Exterior wall panels: Mainly develop construction waste sandstone wall panels. Improve product density, strength, impermeability, freeze-thaw resistance, etc. Strength ≥ 10Mpa, impermeability ≤ 10mm, freeze-thaw ≥ 15 times.

[0165] 1. Crushing and screening of raw materials. The raw materials that do not meet the formula requirements are first crushed and screened. For example, the slag should be crushed to the allowable particle size range in the formula with a pulverizer.

[0166] 2. Ingredients. According to the recipe requirements, after the various raw materials are measured, such as the lifting bucket of the mixer, they are injected into the mixing drum for stirring. And repeat the batching to ensure the continuous work of the mixer. The formula ratio (percentage by weight) is as follows:

[0167] Sand, gravel - 40%, particle size below 8mm.

[0168] Construction waste - 40%, aggregate diameter below 2mm.

[0169] Cement - 20%. According to the requiremen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com