Coal mine roadway geological parameter on-line monitoring system

A geological parameter and monitoring system technology, which is applied to the automatic control system of drilling, measurement, drilling measurement, etc., can solve problems such as excessive deformation of the roadway, poor drilling continuity, and reduced efficiency, and achieve high data processing accuracy. Overcoming the effect of over-intensive data collection and eliminating excessive data fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

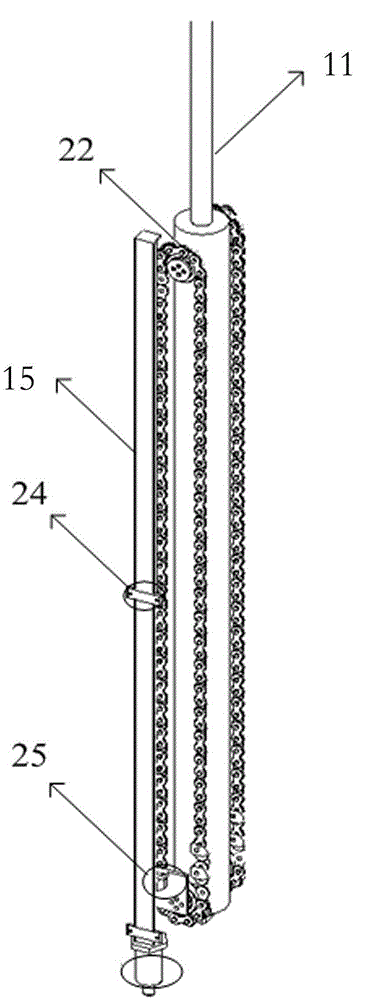

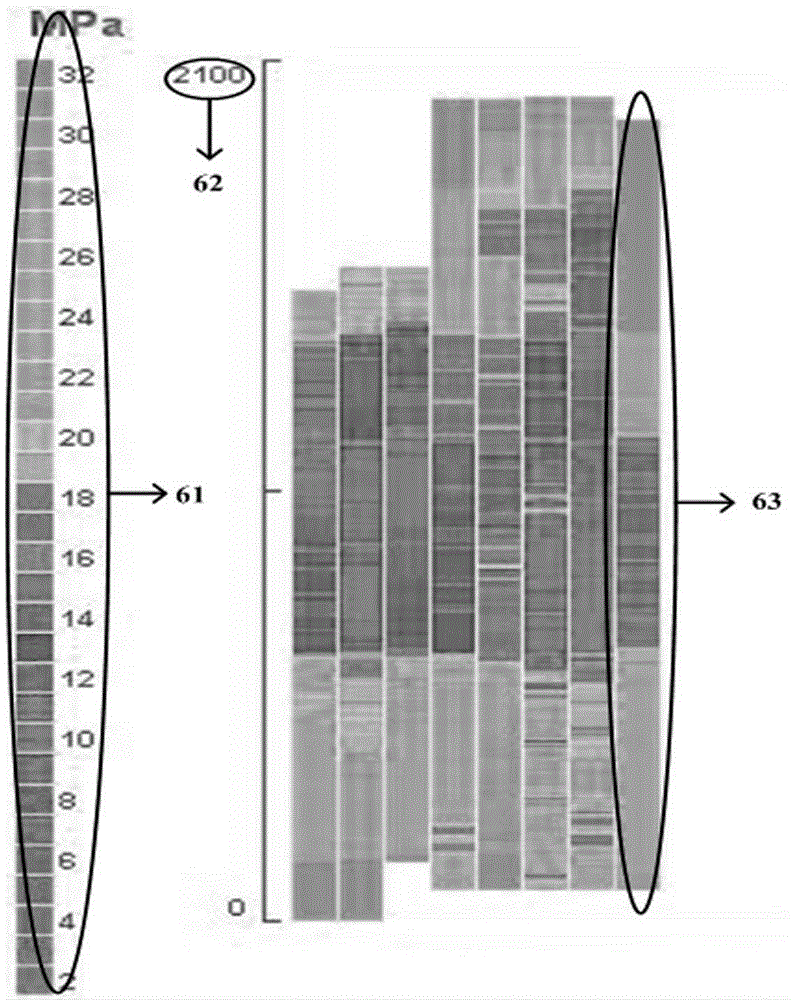

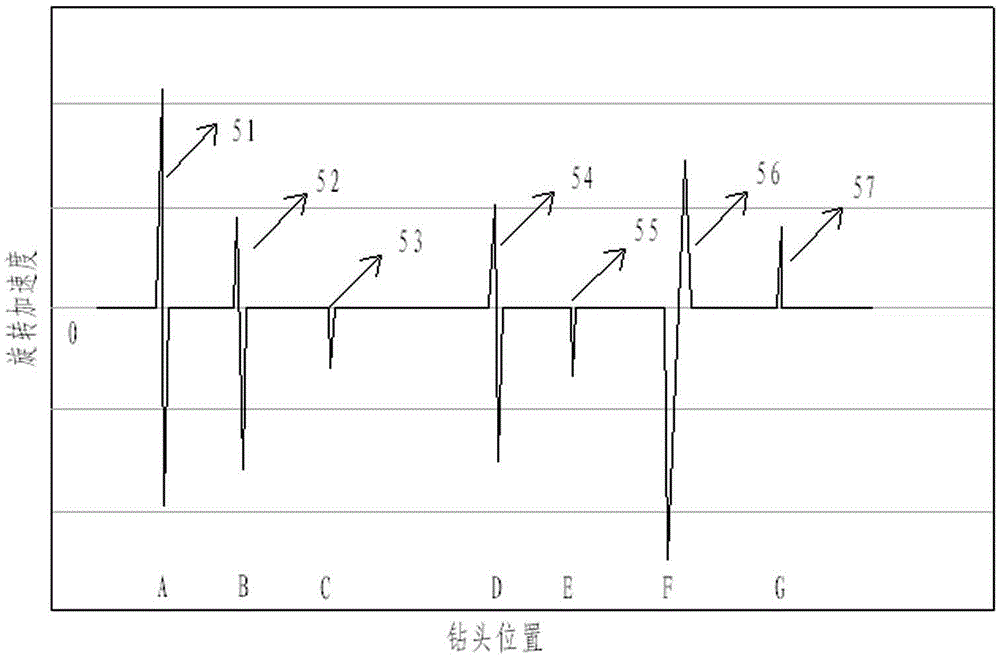

[0038] like figure 1 The coal mine roadway geological parameter on-line monitoring system shown includes a sensor detection element, a data conversion module and a man-machine interface 19, and the sensor detection element includes a feed cylinder pressure sensor 13 installed on a bolter rig 10, a drilling box motor The pressure sensor 14, the external magnetostrictive displacement sensor 15 and the Hall type speed sensor 16, the feed cylinder pressure sensor 13 is installed at the oil inlet of the feed cylinder 11 of the rock bolter 10, and the drilling box motor pressure sensor 14 is installed on the At ports A and B of the drill box motor 12 of the rock bolter 10, an external magnetostrictive displacement sensor 15 is installed on the cylinder body of the feed cylinder 11, and a Hall-type rotational speed sensor 16 is installed on the shell of the drill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com