Sugarcane automatic peeler

A peeler and sugarcane technology, which is applied in the fields of vegetable or fruit peeling, food science, application, etc., can solve the problems of pulp waste, irregular shape of sugarcane, long sugarcane peel, etc., to save space occupied, peeling The effect of uniform thickness and environmentally friendly cutting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

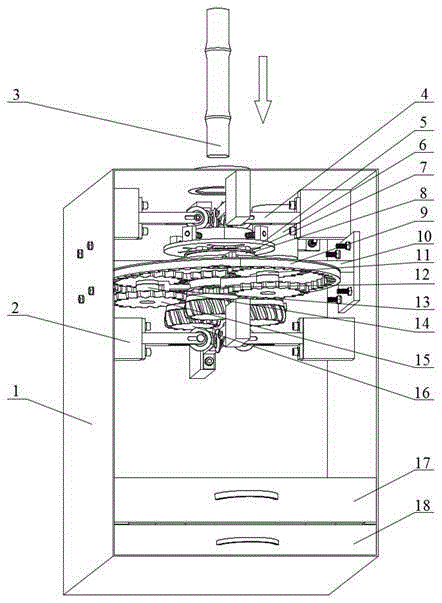

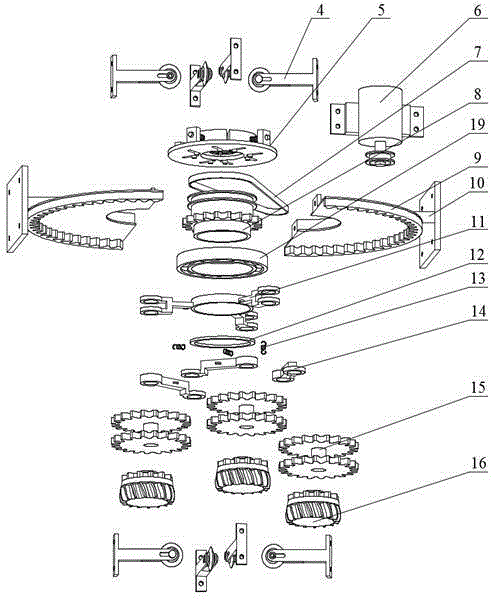

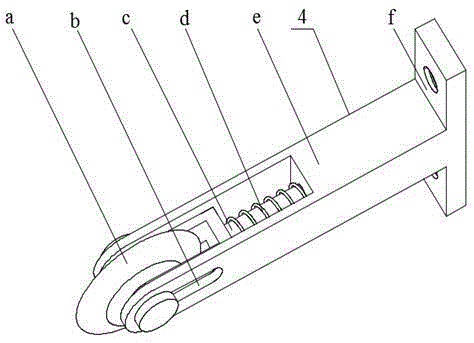

[0027] see figure 1 In the present invention shown, for the convenience of describing the structural principle of the present invention, the spatial orientation is now stipulated as follows: take the sugarcane 3 positions as the top, the following drawer 18 positions as the bottom, and the vertical direction from the top to the bottom; The outside is the front, and the vertical paper surface is inward the rear; the inner end is the direction close to the sugarcane 3 axis, and the outer end is the direction close to the shell of the frame 1. The present invention is mainly composed of a clamping and guiding system, a power system, a feeding system, a cutting system and a collection system from top to bottom. Unless otherwise specified, the components in the present invention are all arranged horizontally.

[0028] see figure 1 with figure 2 , the outside of the present invention is a frame 1, and the frame 1 is surrounded by four baffle plates up and down and around to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com