Elastic buffering feeding device of inner diameter slicing machine and feeding method thereof

A technology of elastic cushioning and internal circle slicing, which is applied in the direction of stone processing tools, manufacturing tools, stone processing equipment, etc., and can solve the problem of low cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

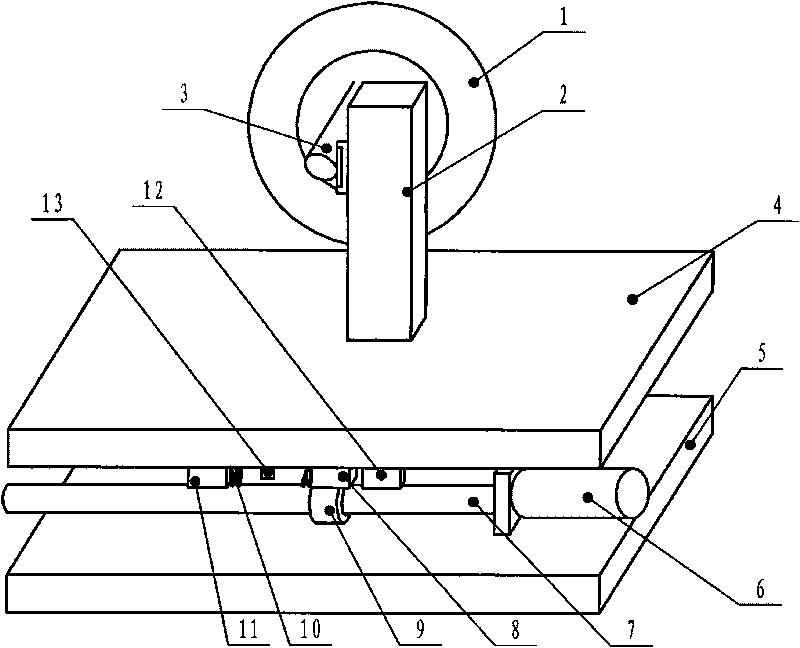

[0045] Embodiment one: figure 1 As shown, this embodiment includes a cutting tool 1 driven by a main motor, an X-axis mobile table 4 driven by a stepping motor 6, and a Y-axis mobile table 5 driven by a stepping motor. The X-axis mobile table 4 is arranged on the Y-axis Above the movable workbench 5, the X-axis movable workbench 4 is provided with a clamping frame 2, and a spring 10 is arranged in the connection device for controlling displacement and force between the X-axis movable workbench 4 and the Y-axis movable workbench 5 . The control transmission connection device of described displacement and force comprises stepper motor 6, and stepper motor 6 is provided with lead screw 7, and lead screw nut 9 is sleeved on lead screw 7, and stepper motor 6 is fixedly installed on the Y-axis mobile work. On the platform 5, the lead screw nut 9 is provided with a load-bearing block 8, one side of the load-bearing block 8 is connected with a spring 10, and one end of the spring 10 ...

Embodiment 2

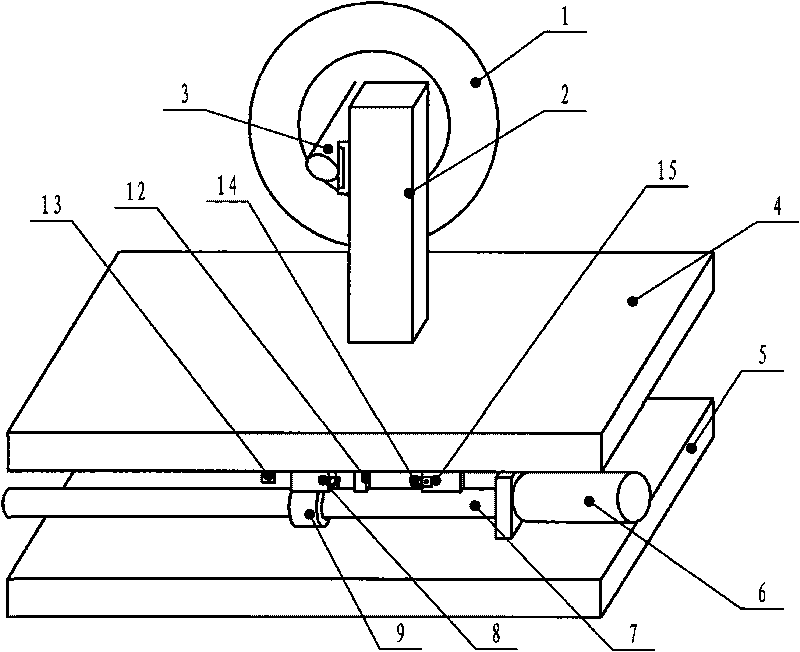

[0050] Embodiment two: figure 2 As shown, the spring of this embodiment is a tension spring 14, and the tension spring 14 is arranged between the load-bearing block and the adjustment piece 15, the stopper 12 and the adjustment piece 15 are fixed on the upper workbench, and the stopper 12 is arranged on the load-bearing Between the block and the adjusting member 15, the extension spring 14 is fixed on the adjusting member 15, and the adjusting member 15 is provided with an adjusting device for adjusting the elastic force of the extension spring (for prior art, so its structural description is omitted), other structures and embodiments One is the same.

[0051] Parameter range of tension spring: compression 1-10 mm, withstand force change of 10 kg. Generally, in the natural static state without cutting, the force of the tension spring is about 0.1 kg; under the condition of maximum force (generally no more than 10 kg), the deformation of the tension spring is 4 mm. Control s...

Embodiment 3

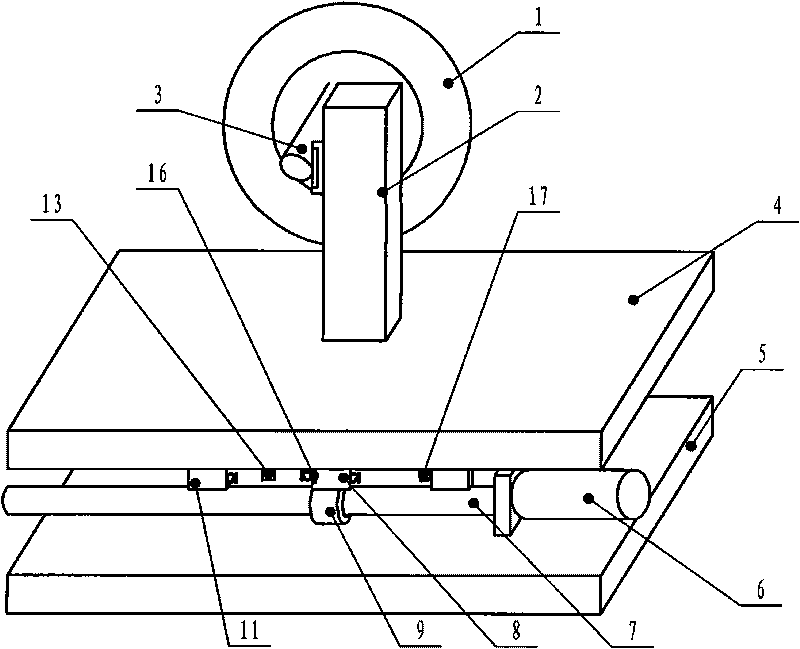

[0052] Embodiment three: image 3 As shown, both sides of the lead screw nut 9 and the bearing block 8 of the present embodiment are provided with tension springs 17 and stoppers, and the stoppers are all fixed on the upper workbench, and the bearing block is also provided with a vibration sensor 16, The limit switch 13 is arranged on the upper workbench, and the limit switch 13 can slide left and right on the upper workbench, that is, an extension spring is respectively connected to both sides of the load-bearing block, and each extension spring is connected with a respective stopper. The structure is the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com