Fully automatic intelligent garbage can

A garbage can, fully automatic technology, applied in the direction of garbage cans, garbage collection, household appliances, etc., can solve the problems of insufficient capacity of garbage bag boxes, inconvenient bag loading and changing, complex structure of garbage cans, etc., to achieve low noise, The operation saves time and effort, and the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

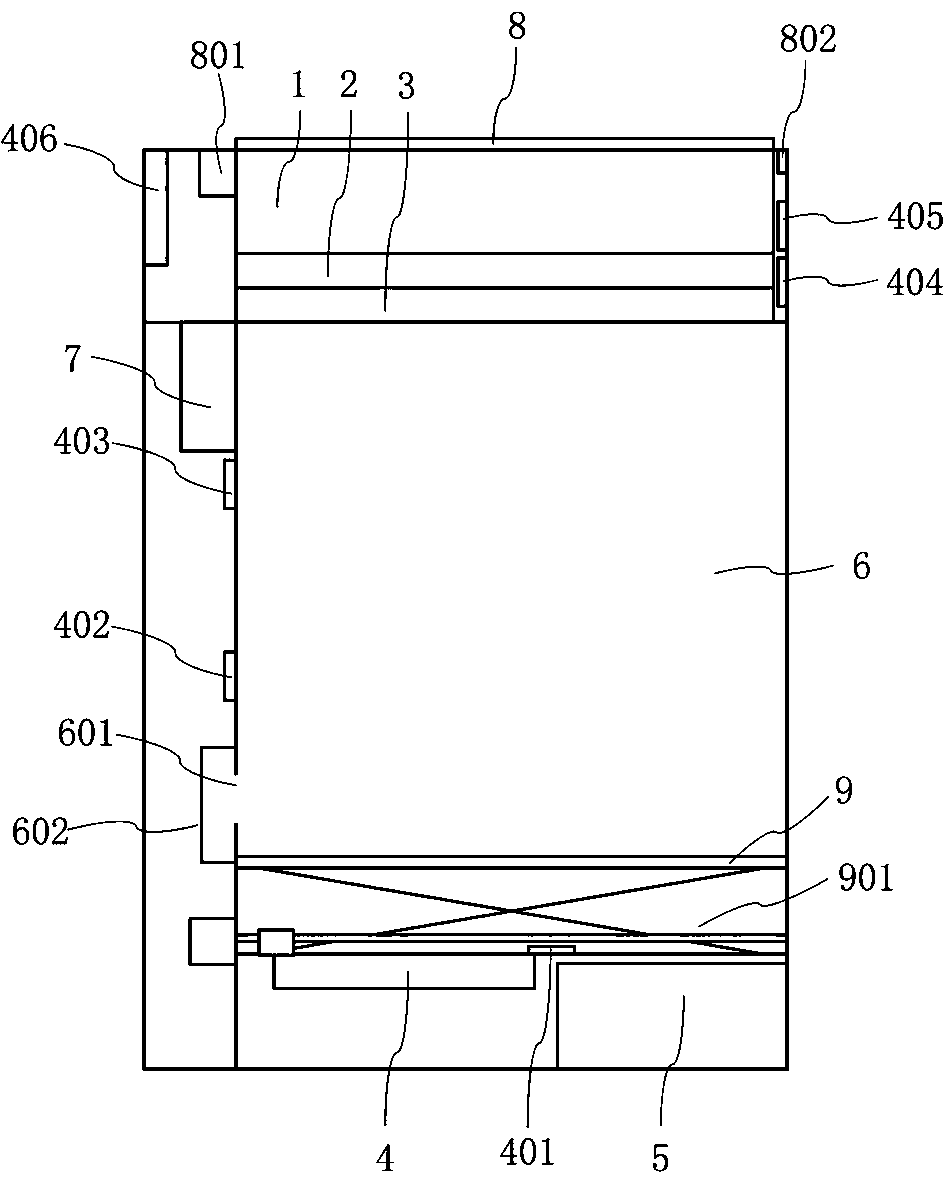

[0036] Such as figure 1 Shown, a kind of full-automatic intelligent dustbin comprises dustbin main body 6, is connected with garbage bag storage device 1 on the top of dustbin main body 6, is installed with garbage bag bag feeding device 2 on garbage bag storage device 1, in garbage bag A garbage bag sealing device 3 is installed below the bag storage device 1, and the garbage bag bag entering device 2 and the garbage bag sealing device 3 are all controlled by a control circuit. Both the control circuit board 4 and the power supply 5 are located under the trash can main body 6 .

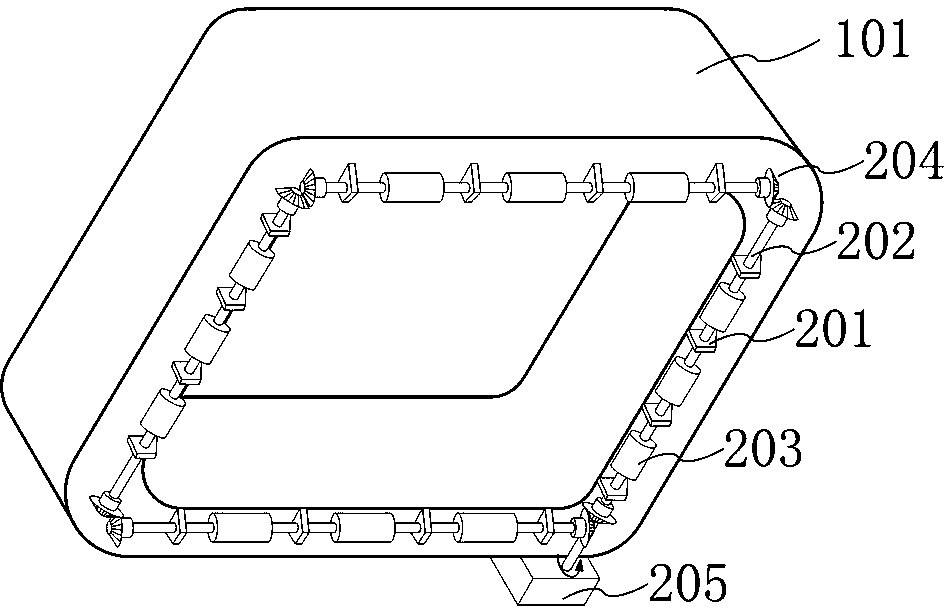

[0037] The garbage bag storage device 1 includes two parts: a bin body 101 and a bin cover 102 . Such as figure 2 , each side of the inner side of the warehouse body 101 is provided with several warehouse body fixing seats 201, there are shaft holes on the warehouse body fixing seats 201, and the warehouse body steel shafts 202 are penetrated into the shaft holes, and several rollers 203 are house...

Embodiment 2

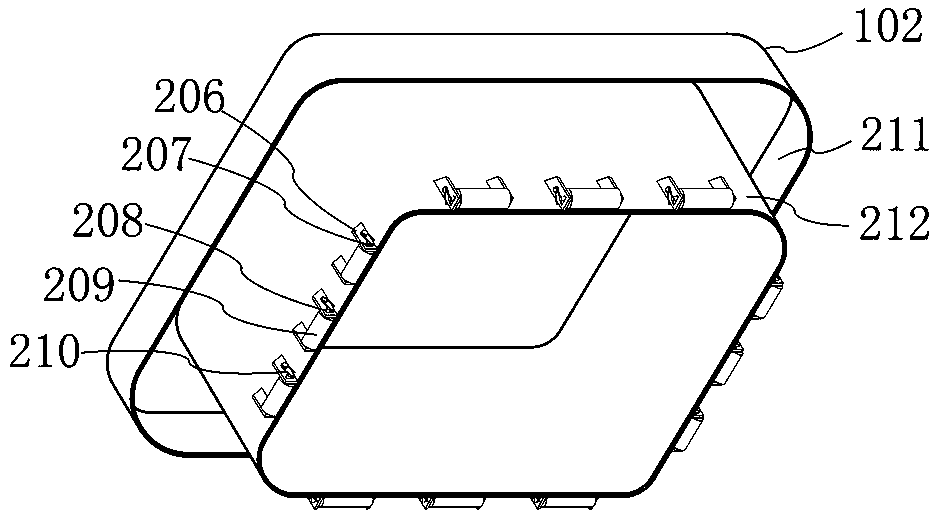

[0057] Such as Figure 8 As shown, in this embodiment, the pressure bag wheel 209 is arranged on the upper edge of the inner side plate of the bin body 101 . A plurality of bag pressing wheels 209 are arranged along the inner side plate of the bin body 101 along a circumference, and the distance between them is substantially uniform. The rollers 203 are arranged on the bottom surface of the cover plate of the bin cover 102 , opposite to each bag pressing wheel 209 . Each bag pressing wheel 209 has its own independent steel shaft, and the bag pressing wheel steel shaft is pushed toward the corresponding roller 203 by the spring. The rollers whose axes are on the same straight line share a steel shaft, and the steel shafts of the rollers are connected by gears or couplings. One of the roller steel shafts is lengthened and passes out to the outer side of the outer plate of the cover to facilitate the connection with the roller driving mechanism.

[0058] The guide plate of the...

Embodiment 3

[0060] Such as Figure 9 As shown, in this embodiment, the pressure bag wheel 209 is arranged on the side of the inner side plate of the bin body 101 . A plurality of bag pressing wheels 209 are arranged along the side of the inner side plate of the bin body 101, and the distance between them is basically uniform. The rollers 203 are arranged on the side of the guide plate 212 of the bin cover 102 , and the length of the guide plate 212 is shorter than the length of the bin body 101 . The rollers 203 are opposite to each pressure bag wheel. Each bag pressing wheel 209 has its own independent steel shaft, and the bag pressing wheel steel shaft is pushed toward the corresponding roller 203 by the spring. All rollers whose axes are on the same straight line share a roller steel shaft, and the roller steel shafts are connected by gears or couplings. Also be provided with a vertical shaft 214, its lower end is equipped with gear, and this gear is meshed with the gear of one of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com