Atmospheric discharging cold plasma generator and array based on contraction and enlargement channel structure

A technology of cold plasma and channel structure, which is applied in the manufacture of plasma, discharge tubes, semiconductor/solid-state devices, etc., can solve the problems of limiting the effective distance of active particles in cold plasma, increasing the cost of use, etc., so as to improve the effective space Movement distance and effective space range, the effect of increasing jet velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

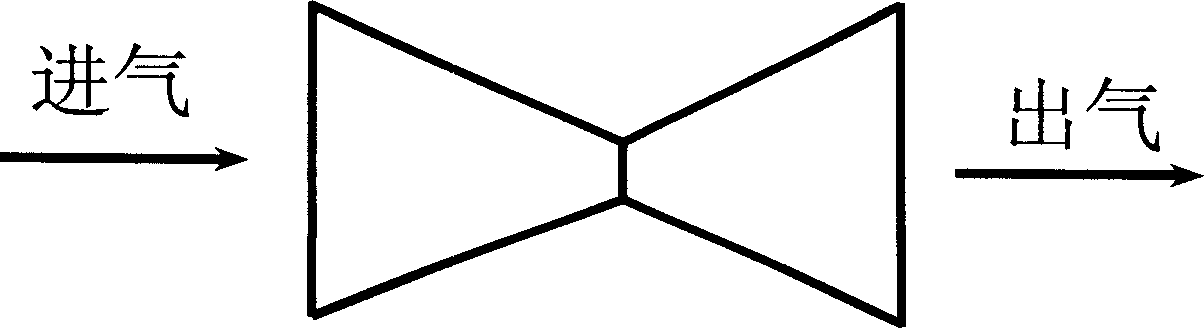

[0049] The present invention adopts such as figure 1 Scaled channel shown. By adjusting the intake pressure and scaling the cross-sectional area of the throat of the channel (at the minimum cross-section of the channel), the airflow reaches the local sound velocity at the throat. In the subsequent expansion stage, the flow velocity will increase with the increase of the nozzle cross-sectional area, so as to realize the quality Significantly increase the gas outlet flow rate with a small increase in flow rate. The scaling structure of the scaling channel can be applied at the inlet of the cold plasma generator, the discharge and the gas outlet, and the cross section of the scaling channel can be made into a circular, square, or elliptical shape, all of which can realize the improvement of gas The purpose of outlet flow rate.

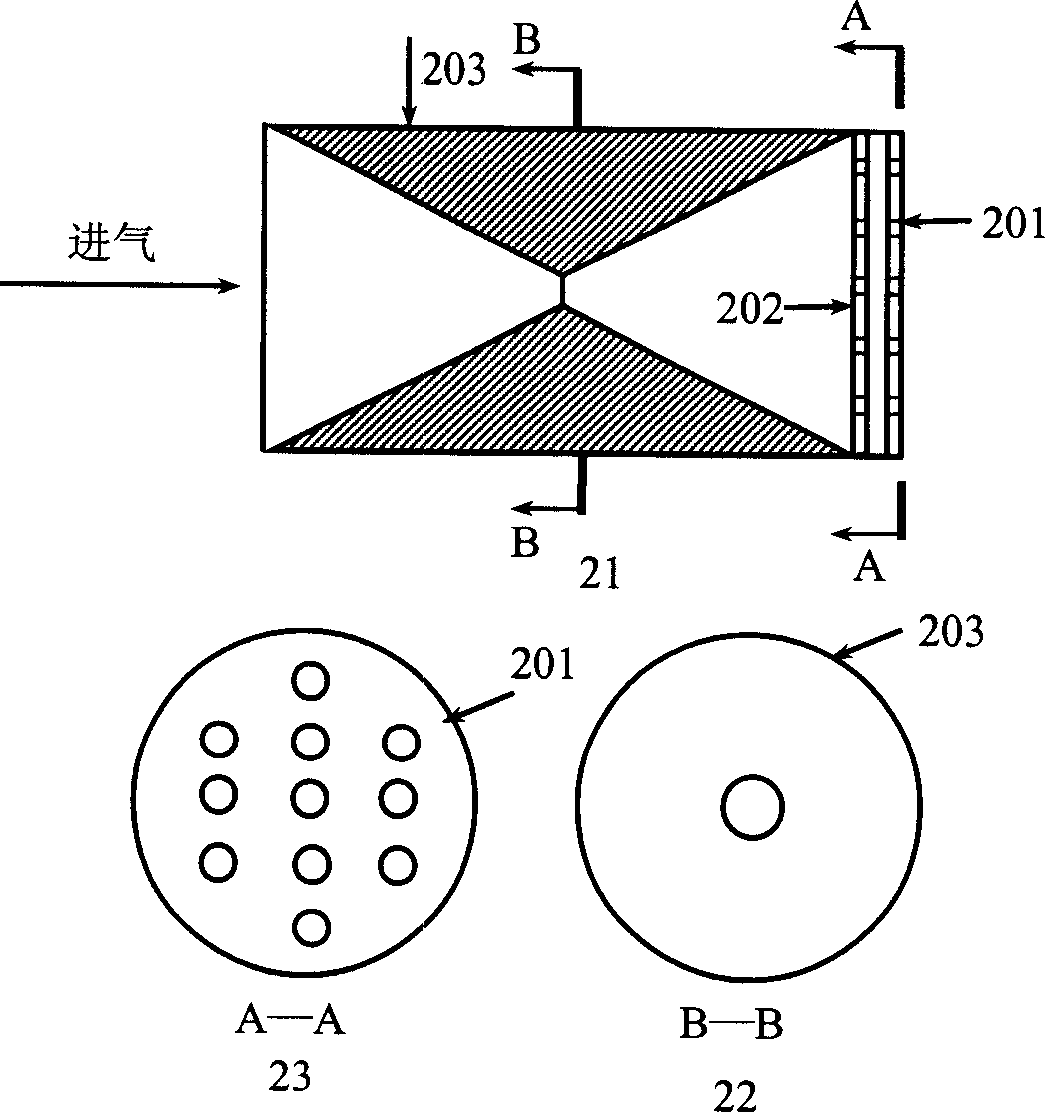

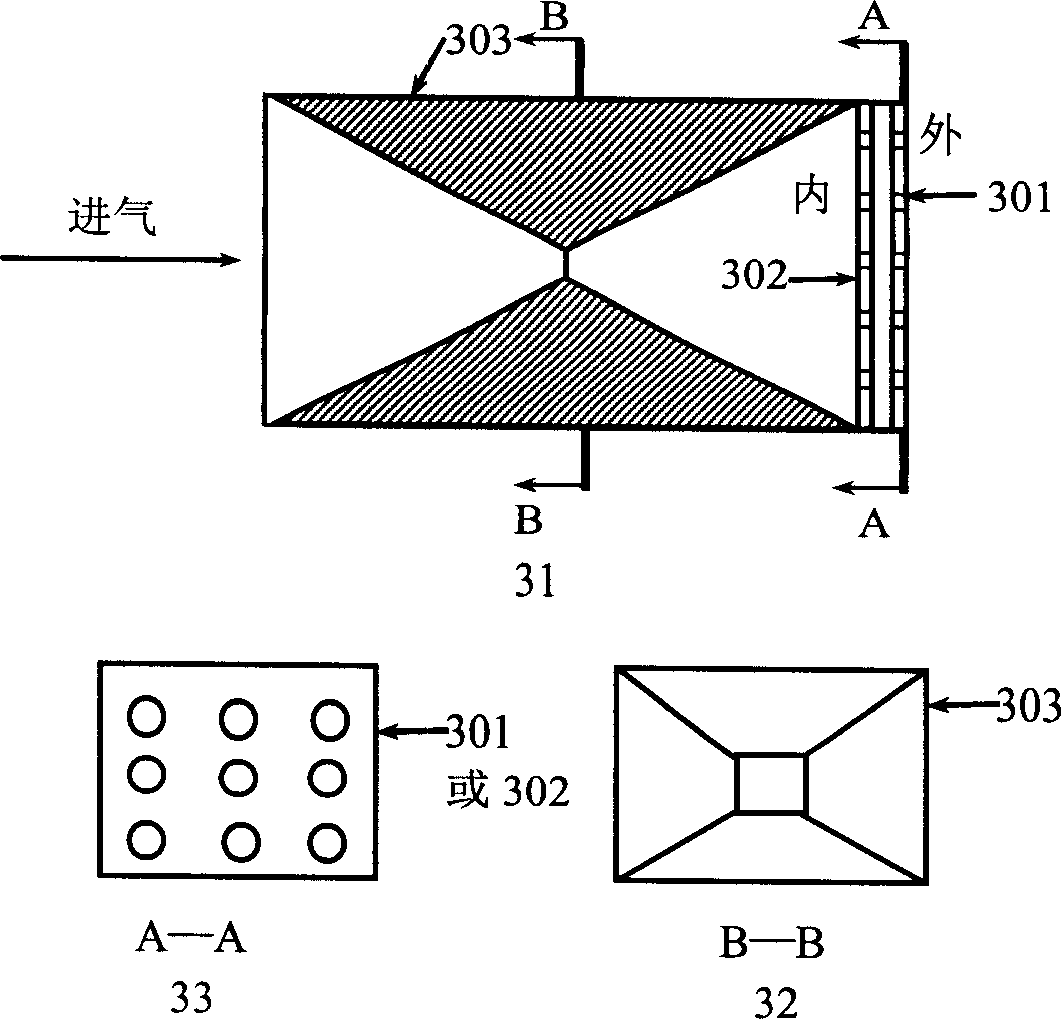

[0050] Figure 2-11 The typical application of the scaling channel structure design on some atmospheric pressure discharge cold plasma generators is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com