Circumferential staggered self-circulating casing treating method for axial-flow compressor

An axial-flow compressor and casing processing technology, which is applied in the directions of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve problems such as poor stability expansion capability, weak ability to stabilize the working range of axial flow compressors, and incompatibility. , to achieve the effect of improving the stability expansion ability, increasing the jet flow velocity, and increasing the bleed air volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

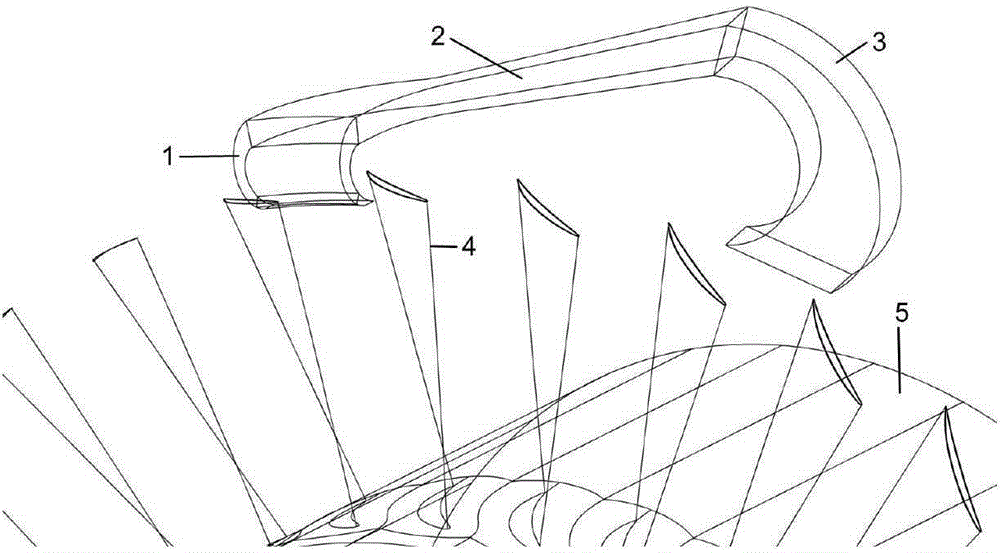

[0014] refer to Figure 1-2 . The specific steps of the treatment method for the circumferentially dislocated type self-circulating casing of the axial flow compressor of the present invention are as follows:

[0015] The invention is applied to the isolated rotor of the axial flow compressor laboratory of Northwestern Polytechnical University, the radius of the rotor case is 0.149 meters, and the number of rotor blades is 30. The air injection device 1, the bridge 2 and the air induction device 3 form a self-circulating casing on the top of the rotor blade.

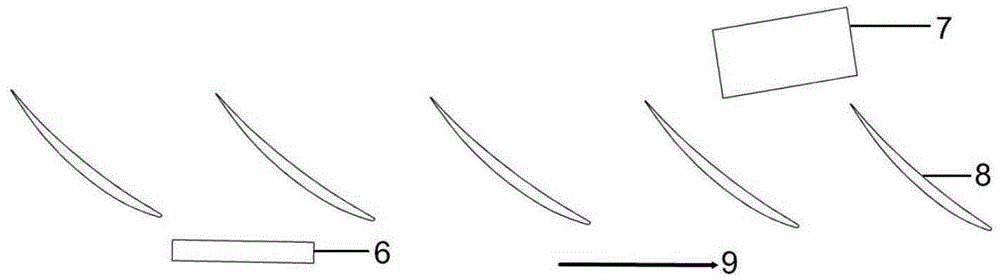

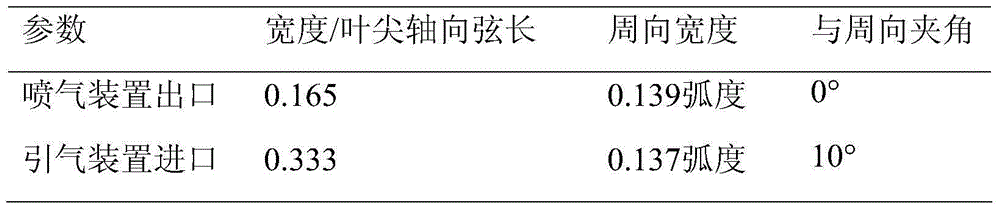

[0016] 1. The air-inducing device 3 is arranged on the wall of the compressor casing. The air-inducing device 3 is located on the casing surface at the downstream of the rotor blade top 8 channel. The air-inducing device 3 rotates at a certain angle along the circumferential direction 9 to make the rotor blade top 8 The absolute airflow direction of the outlet is aligned with the contour 7 of the bleed air device on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com