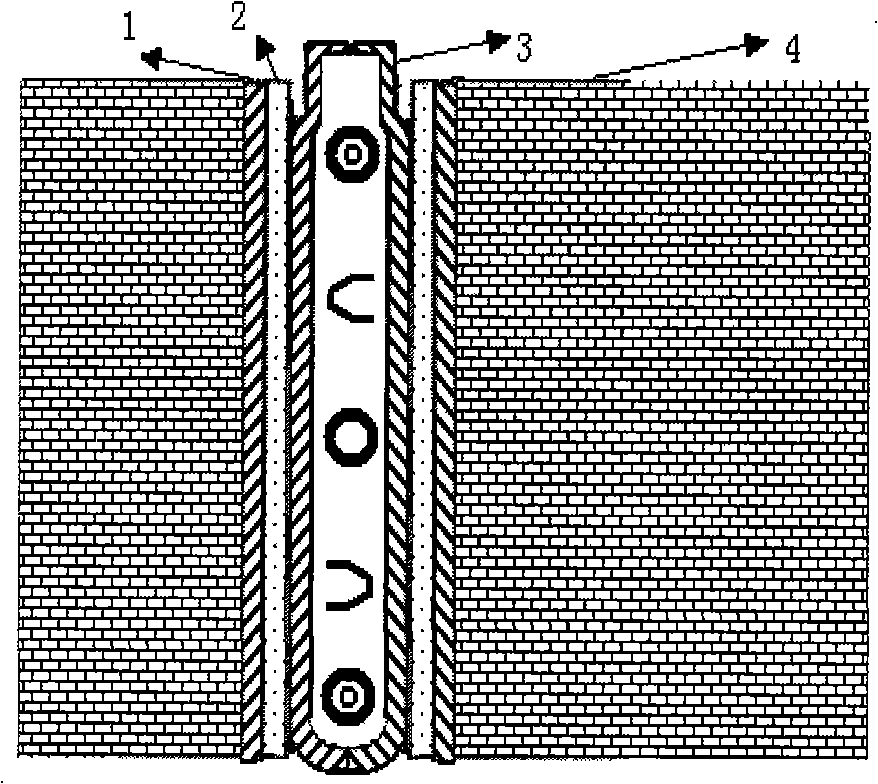

Perforating bullet

A perforating charge, a new type of technology, applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problem of loss, achieve the effect of enhancing the force and reducing the loss of flight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

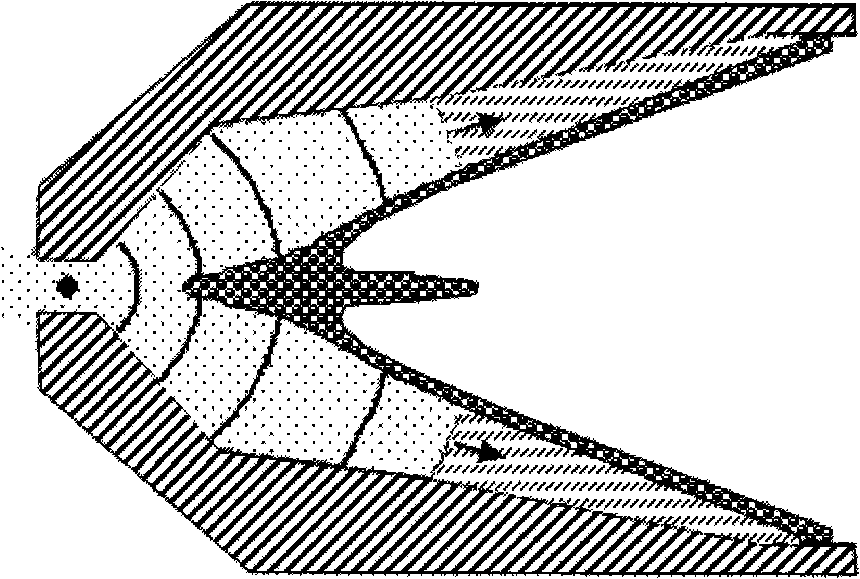

[0044] At present, the design of perforating charges is mainly completed through theoretical analysis, numerical simulation and experiment, and numerical simulation is more and more valued by domestic and foreign perforating charge manufacturers because of its short cycle and low cost. The numerical simulation program used in this embodiment is a two-step Euler program, and the problems that can be simulated include:

[0045] (1) Detonation issues such as the formation, propagation and interaction with other media of detonation waves;

[0046] (2) Matter movement issues such as the formation, movement, extension, and fracture of jets under high temperature and high pressure;

[0047] (3) Penetration of the target by the jet, crater formation and dynamic response of the target;

[0048] Therefore, it is more suitable to simulate the perforation problem of petroleum projectiles.

[0049] As a comparison between the checksum of the calculation program and the test results, the ...

Embodiment 2

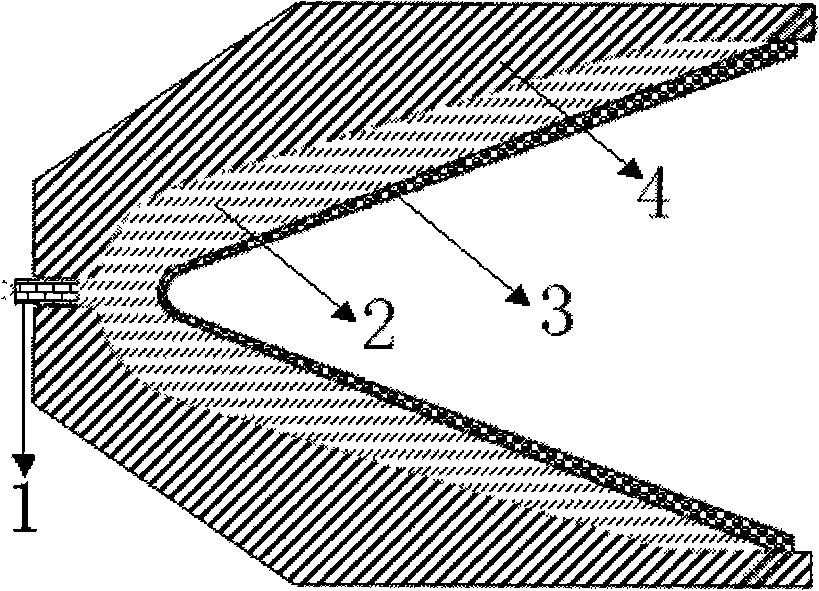

[0060] The feature of shaper in the present invention:

[0061] The effect of adding a shaper is to effectively hinder the propagation of detonation waves. When the detonation wave hits the shaper, a shock wave will be generated inside the device, and the velocity and pressure of the shock wave should be as low as possible, so as to delay the time for the detonation wave to reach the bottom of the shaper and ensure the explosion in the booster channel. The blast wave reaches the interface of the main charge first; the low pressure can reduce the probability of the shock wave accidentally detonating the main charge. Ensure ring detonation of the main charge.

[0062] According to the above requirements, the material of the shaper should be an inert substance with low density and low sound velocity, and must have a certain strength to ensure that the shaper will not be crushed when the explosive is loaded in the whole bomb production. Low density means that the density is lower...

Embodiment 3

[0068] The numerical simulation results of the new perforating charges of different projectile types are given below, and the numerical simulation results of the corresponding traditional perforating charges without shapers are also given for comparison, as shown in Table 3.

[0069] Table 3 lists the values of the important parameters of the jet part obtained from the numerical simulation, and -M in the model code in the table indicates a new type of perforating charge with a shaper installed. For example, D01 is a traditional perforating bullet, while D01-M is a new type of perforating bullet with a shaper added to the D01 bullet.

[0070] The physical meaning of each symbol in the table is as follows: U-jet head velocity, M-jet mass, Z-jet length, E K - jet kinetic energy, L - jet penetration depth of concrete target, η = E K M / E K - Kinetic energy ratio of old and new perforating charges, ξ=L M / L-the ratio of the penetration depth of the old and new perforating cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com