Double-focusing linear jet cutter

A kind of energy-concentrating cutter and double-focusing technology, which is applied in blasting and other directions, can solve the problems of insufficient power and effect, and achieve the effect of increasing power, broad development prospects and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

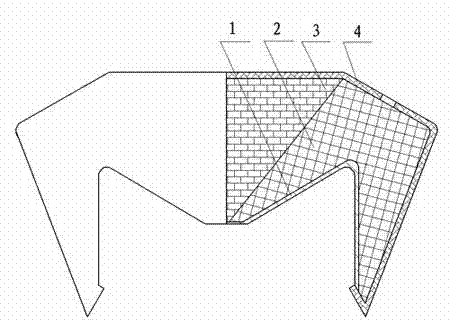

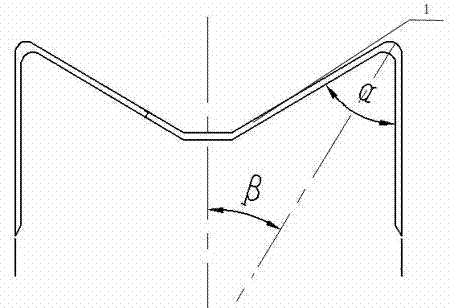

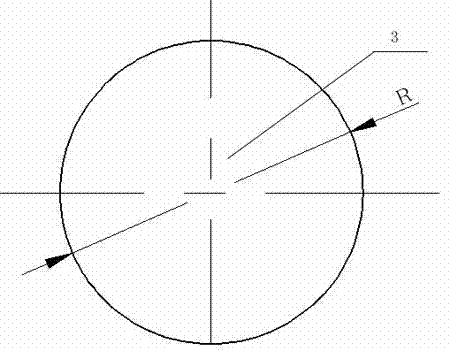

[0012] Such as figure 1 As shown, the double-focus linear energy-concentrating cutter is composed of a drug-shaped cover 1, an explosive 2, a waveform adjuster 3, and a housing 4. figure 2 It is a part diagram of drug-type cover 1, image 3 It is a part diagram of the waveform adjuster 3, Figure 4 It is the housing 4 parts diagram. The drug-shaped cover 1 is composed of two traditional wedge-shaped covers. The explosive 2 is placed in the two wedge-shaped covers. There is an angle between the centerlines of the two wedge-shaped covers. The wave adjuster 3 is located between the angles. To reduce the mutual influence between charges on both sides, a detonator hole is arranged at the midpoint of the two edges of the casing 4, and the detonation mode is initiated at the midpoint of the two edges of the casing. After the charge is detonated, two jets are respectively formed along the two wedge-shaped corners of the drug-shaped cover 1 . The two jets converge again on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com