Deep penetration large-aperture perforating bullet

A technology of large aperture and perforating charges, which is applied in the fields of fluid production, wellbore/well components, and earth-moving drilling, etc., can solve the problem of not being able to form casing oil and gas well formations at the same time, and achieve high speed, broad development prospects, and improved The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

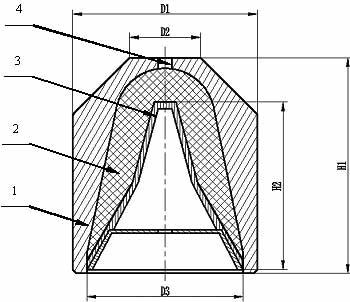

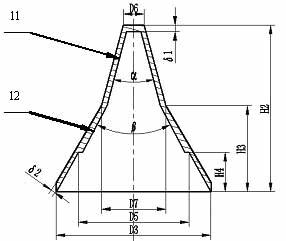

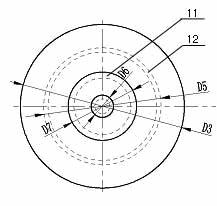

[0015] Such as figure 1 As shown, the deep-penetrating large-aperture perforating charge assembly structure is composed of shell 1, charge 2, charge cover 3 and detonating device 4; as diagram 2-1 , 2-2 As shown, the outer drug-shaped cover is improved on the basis of the traditional metal powder double-cone drug-shaped cover, which is composed of an upper cover body 11 with a small cone angle and a lower cover body 12 with a large cone angle; Figure 3-1 , 3-2 As shown, in the truncated cone-shaped lower cover body 13 with holes in the inner layer, the cone angle of the medicine-shaped cover is β, the height is H4, the wall thickness is δ3, the central opening diameter is D8, the diameter of the upper end surface is D5, and the diameter of the lower end surface is D3. The shaped lower cover body 13 is embedded in the lower cover body 12 with a large cone angle to form a fit; the shell structure is as follows Pic 4-1 , 4-2 As shown, the shape of the shell is composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com