Ultrahigh-pressure water jet cutting machine nozzle

A water cutting machine, ultra-high pressure technology, applied in spray guns, explosion generating devices, abrasives, etc., can solve the problems of low cutting efficiency, low cutting speed, and small water specific gravity, and achieve strong erosion and material removal capabilities. Increase cutting efficiency and specific gravity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

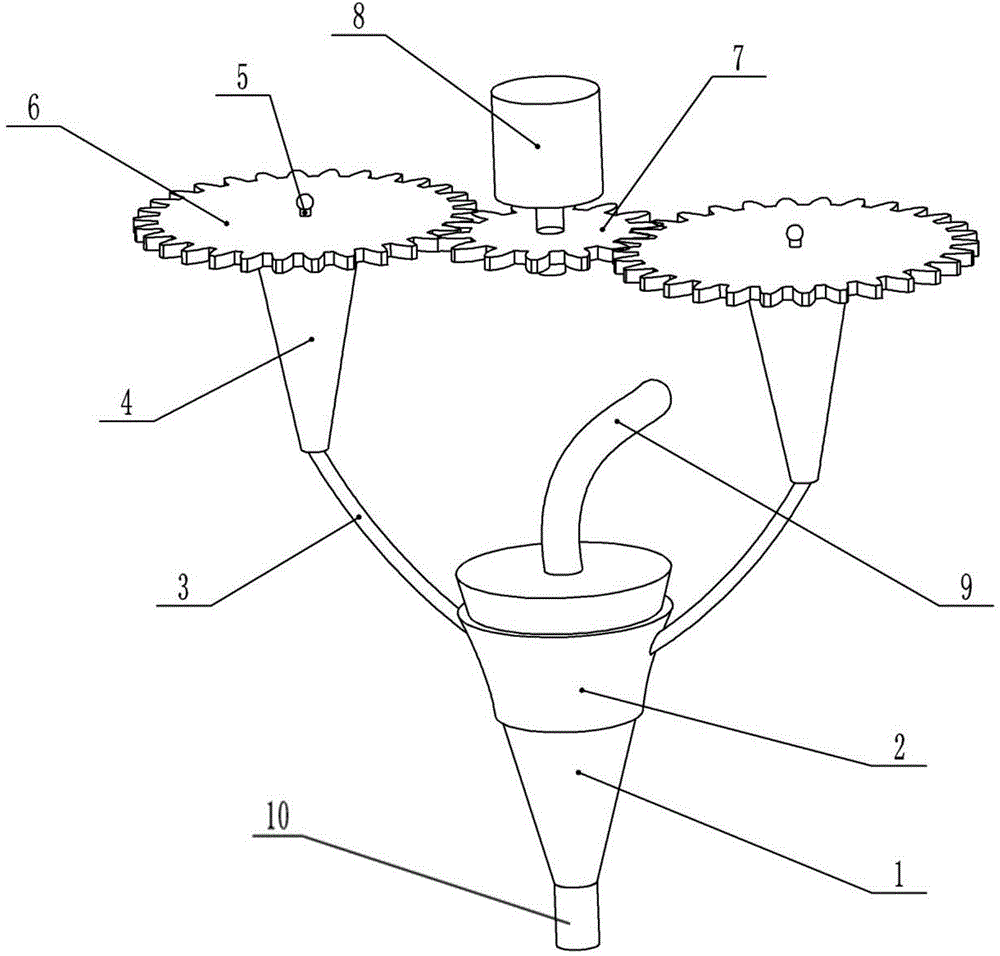

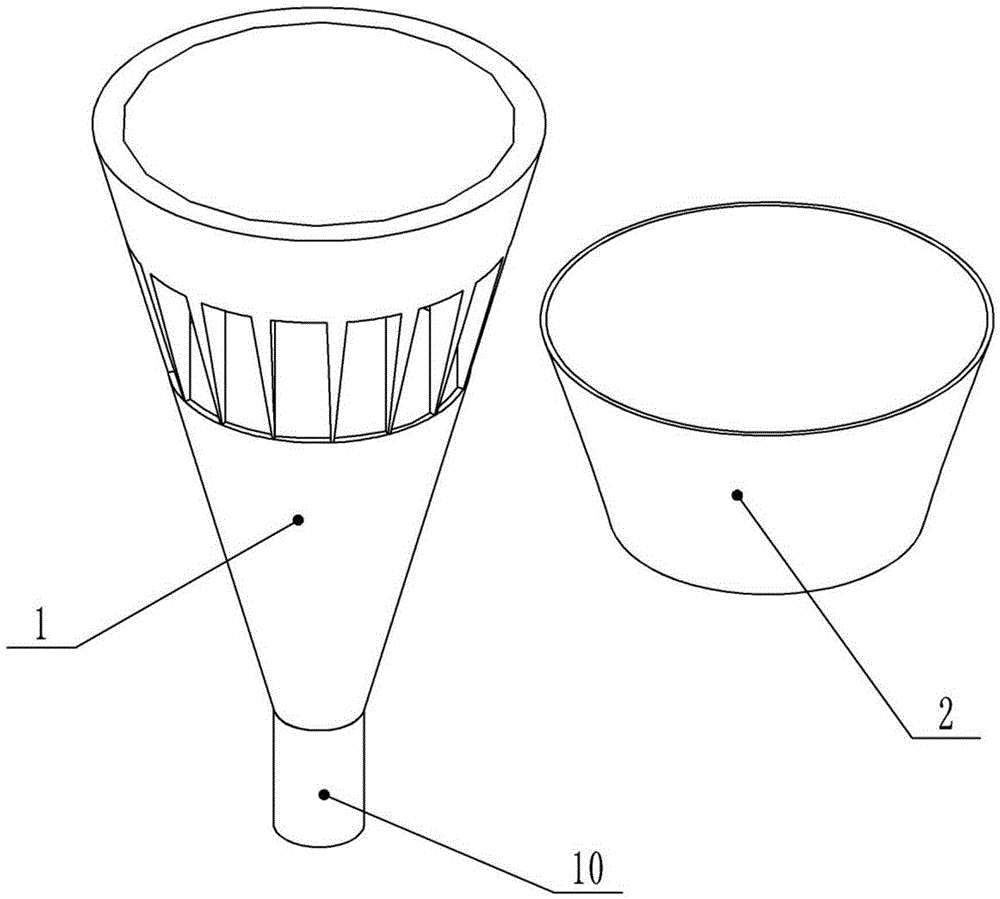

[0027] Such as figure 1 As shown, the present embodiment provides a nozzle for an ultra-high pressure water cutting machine, including a hollow nozzle body 1, the nozzle body 1 is conical, such as figure 2 As shown, the side wall is processed with several through holes. The sealing sleeve 2 is set on the nozzle body 1. The sealing sleeve 2 can rotate and seal the outer wall of the nozzle body 1. The liquid outlet (lower end) of the nozzle body 1 is provided with a guide channel 10. The diameter of the guide channel 10 is equal to that of the nozzle body. 1 The aperture of the liquid outlet, the length of the guide channel is equal to 2-3 times the aperture. The upper end of the nozzle body 1 communicates with the high-pressure water pipe 9 .

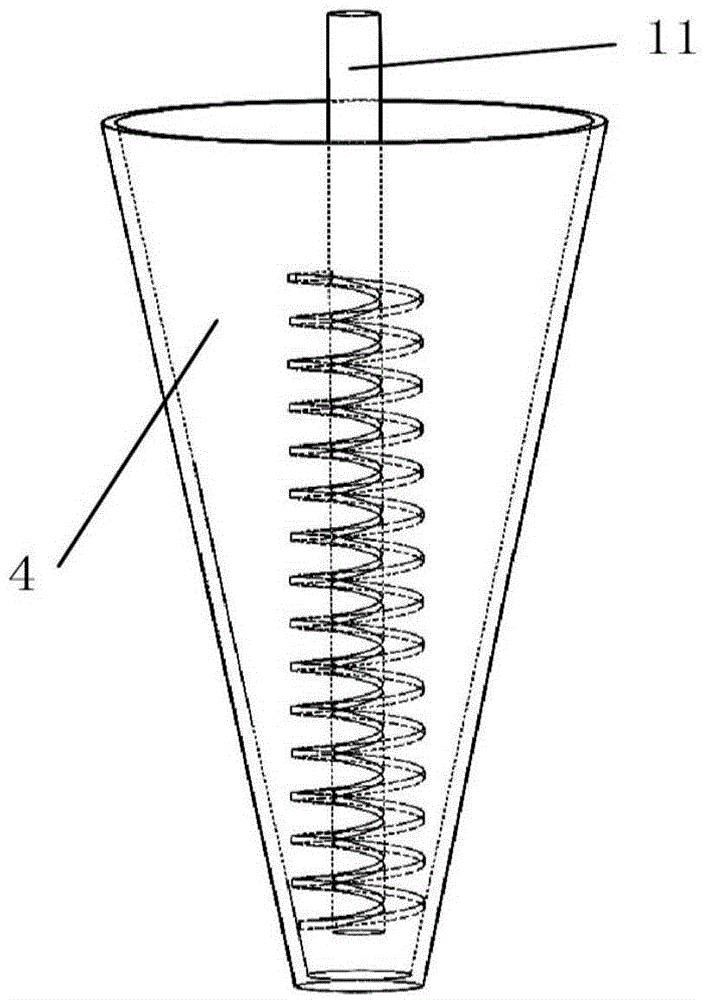

[0028] Such as figure 1 and image 3 As shown, the abrasive device includes a spiral reamer 11, a transmission gear 6 and a conical hollow cylinder 4. The hollow cylinder 4 is provided with a feed port and a discharge pipe 3, and th...

Embodiment 2

[0031] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the discharge pipe 3 is a pipe with higher hardness, and the two rotating shafts 5 and the driving motor 10 are all welded on the rotating disk 12, and the rotating disk 12 is welded with a rotating handle or turn the motor.

[0032] During operation, since the sealing sleeve 2 is sleeved on the nozzle body 1 and can rotate, the rotating disc 12 can drive the abrasive device to rotate, so the discharge pipe 3 is still rotating while discharging, and the abrasive can be rotated from different directions. Mix into high pressure water for more even mixing and better results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com