Ultrasonic nozzle for use in metallurgical installations and method for dimensioning an ultrasonic nozzle

A technology for supersonic nozzles and metallurgical equipment, applied in lighting and heating equipment, special data processing applications, computer-aided design, etc., can solve problems such as the need to replace gun heads, achieve good internal flow characteristics, simplify installation or operation, and save copper material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Different embodiments of the disclosure are described below, wherein the same reference symbols are used for identical or similar components and a repeated description is partially omitted.

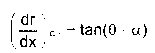

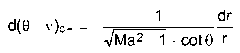

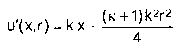

[0030] Figure 1 shows the schematic Mach number distribution inside and outside of a Laval supersonic nozzle (which operates with oxygen). Oxygen enters the atmosphere here at 1650°C.

[0031] It is evident here that in the design state shown in Figure 1a, ie when the pressure p at the outlet cross-section e equal to the ambient pressure p u , allowing essentially undisturbed flow.

[0032] The underexpansion (Unterexpansion) is shown in Figure 1b, where the ambient pressure p u is less than the pressure p at the outlet cross-section e . Disturbing jet streams are clearly recognizable here.

[0033] In Fig. 1c is shown the overexpansion (Ueberexpansion), ie in which the ambient pressure p u greater than the outlet cross-section p e place pressure. There is also a disturbin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com