Heat pipe type superhard abrasive material grinding tool

A super-abrasive, heat-pipe technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the actual needs of grinding and cooling, super-abrasive tools or parts burn, grinding arc temperature Lifting and other problems, to achieve the effect of simple structure, improved service life, and satisfactory heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

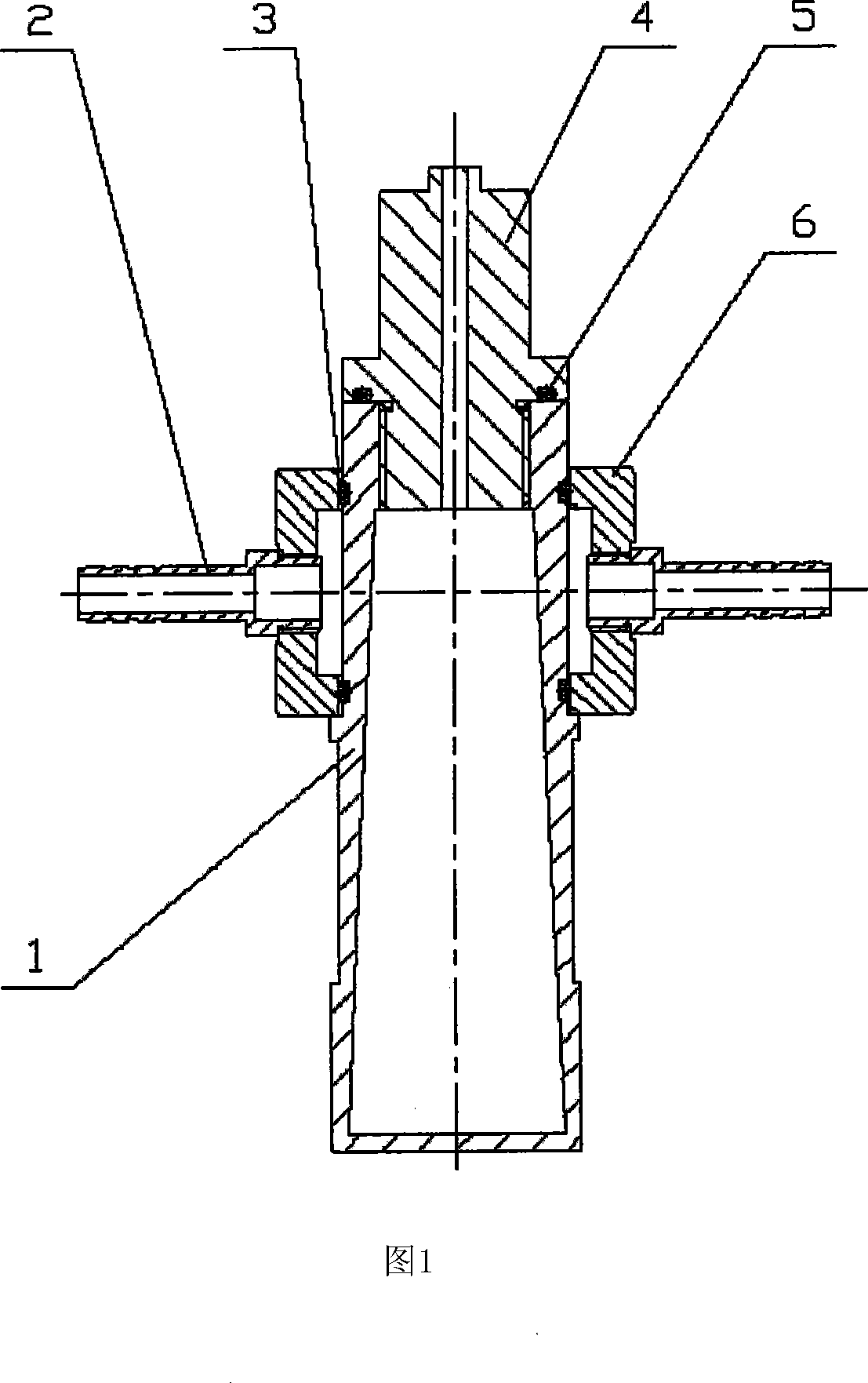

[0012] Below in conjunction with accompanying drawing, introduce the content of the present invention in detail.

[0013] 1 is a schematic diagram of the structure of the superabrasive abrasive tool of the present invention. The abrasive tool structure is composed of a grinding head 1 and a grinding head handle 4. The cooling device is composed of a pipe joint 2, a sealing ring 3, a sealing ring 5 and a water jacket 6. When assembling, the sealing ring 3 can be installed on the grinding head 1 first, then the sealing ring 5 can be installed on the grinding head handle 4, and then the grinding head handle 4 can be screwed into the grinding head 1 and pressed tightly, and then through the grinding head handle The hole on 4 draws a vacuum to the working chamber in the grinding head 1 and seals it. Finally, the water cooling device composed of the pipe joint 2 and the water jacket 6 is installed on the grinding head 1 . During grinding, the heat generated by grinding is transferre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com