Metal material composite electrodeposition diamond grinding pad and manufacturing method thereof

A composite electrodeposition, metal material technology, applied in the direction of manufacturing tools, metal processing equipment, abrasives, etc., can solve the problem of reduced grinding temperature, high equipment power and thermal requirements, unable to completely change the heat resistance of polymer material binders, etc. problem, to achieve the effect of not easy to block and improve strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0034] Example 1: a metal material composite electrodeposited diamond grinding disc manufacturing method, is characterized in that, comprises the following steps:

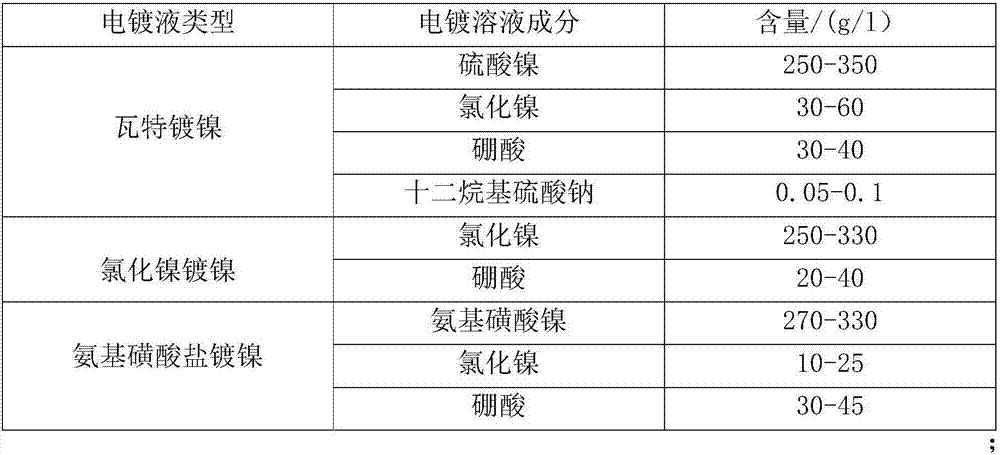

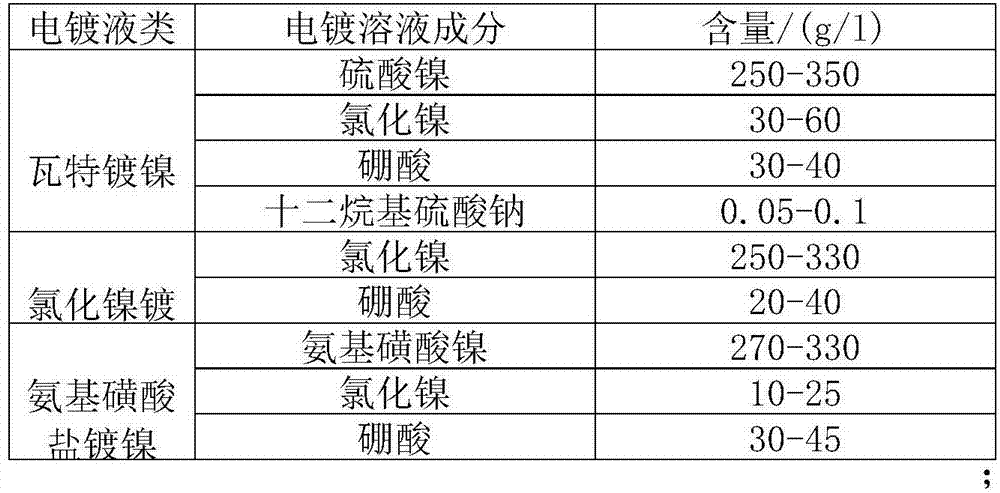

[0035] (1) Configure the plating solution:

[0036] Nickel sulfate 300g / L, nickel chloride 50g / L, boric acid 36g / L, sodium lauryl sulfate 0.1g / L;

[0037] (2) Cutting the substrate: select a 0.1mm thin iron plate, cut it into a Φ80mm disc, and make it into a substrate;

[0038] (3) Degreasing: Place the substrate in a container filled with degreasing agent and heat it to 80°C for 30 minutes to degrease;

[0039] (4) Rust removal: place the substrate in a container filled with hydrochloric acid, soak for 1 hour without heating, and remove the scale;

[0040] (5) Molding insulation: cover the mold on one side of the substrate, and cover the parts that do not need to be plated with insulating materials;

[0041] (6) Empty plating: After the substrate is put into the tank, electroplate for 5 minutes at a current den...

example 2

[0047] Example 2: a metal material composite electrodeposited diamond grinding disc manufacturing method, is characterized in that, comprises the following steps:

[0048] (1) Configure the plating solution:

[0049] Nickel chloride 250g / L, boric acid 25g / L, sodium lauryl sulfate 0.1g / L;

[0050] (2) Cutting the substrate: select a 0.02mm thin copper plate, cut it into a Φ100mm disc, and make it into a substrate;

[0051] (3) Degreasing: Place the substrate in a container filled with degreasing agent and heat it to 100°C for 30 minutes to degrease;

[0052] (4) Rust removal: place the substrate in a container filled with sulfuric acid, soak for 1 hour without heating, and remove the scale;

[0053] (5) Molding insulation: cover the mold on one side of the substrate, and use insulating materials to cover other places that do not need to be plated;

[0054] (6) Empty plating: After the substrate is put into the tank, electroplate for 20 minutes at a current density of 1 amper...

example 3

[0060] Example 3: a metal material composite electrodeposited diamond grinding disc manufacturing method, is characterized in that, comprises the following steps:

[0061] (1) Configure the plating solution:

[0062] Nickel sulfamate 300g / L, nickel chloride 50g / L, boric acid 36g / L, sodium lauryl sulfate 0.1g / L;

[0063] (2) Cutting the substrate: Select the conductive cloth, cut it into a Φ80mm disc, and make it into a substrate;

[0064] (3) Degreasing: Place the substrate in a container filled with degreasing agent and heat it to 40°C for 30 minutes to degrease;

[0065] (4) Rust removal: The conductive cloth can be used without rust removal, or soaked in a very dilute hydrochloric acid solution, and cleaned;

[0066] (5) Molding insulation: cover one side of the substrate with insulating material, and cover other places that do not need to be plated with insulating material;

[0067] (6) Empty plating: After the substrate is put into the tank, electroplate for 5 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com