Ultra-hard diamond grinding wheel free of binding agent and manufacturing method of ultra-hard diamond grinding wheel

A diamond grinding wheel, bond-free technology, applied in the direction of bonded grinding wheels, manufacturing tools, metal processing equipment, etc., to achieve the effect of reducing the grinding temperature, uniform distribution, and improving the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

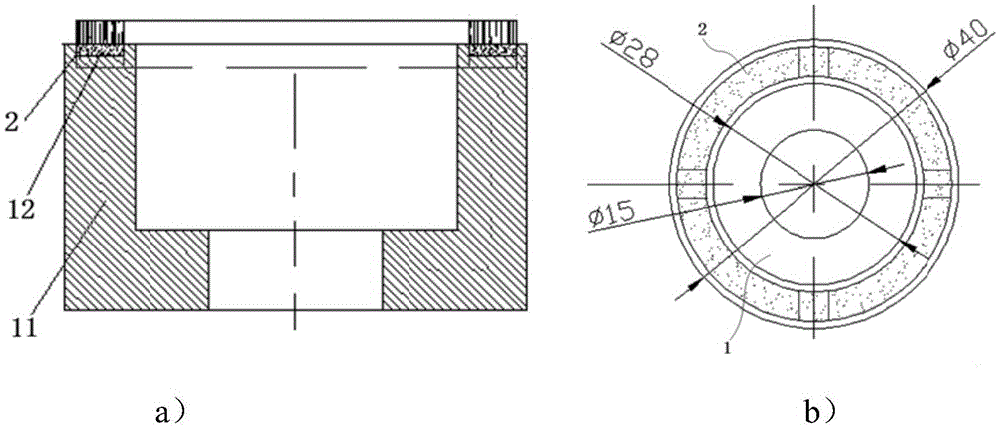

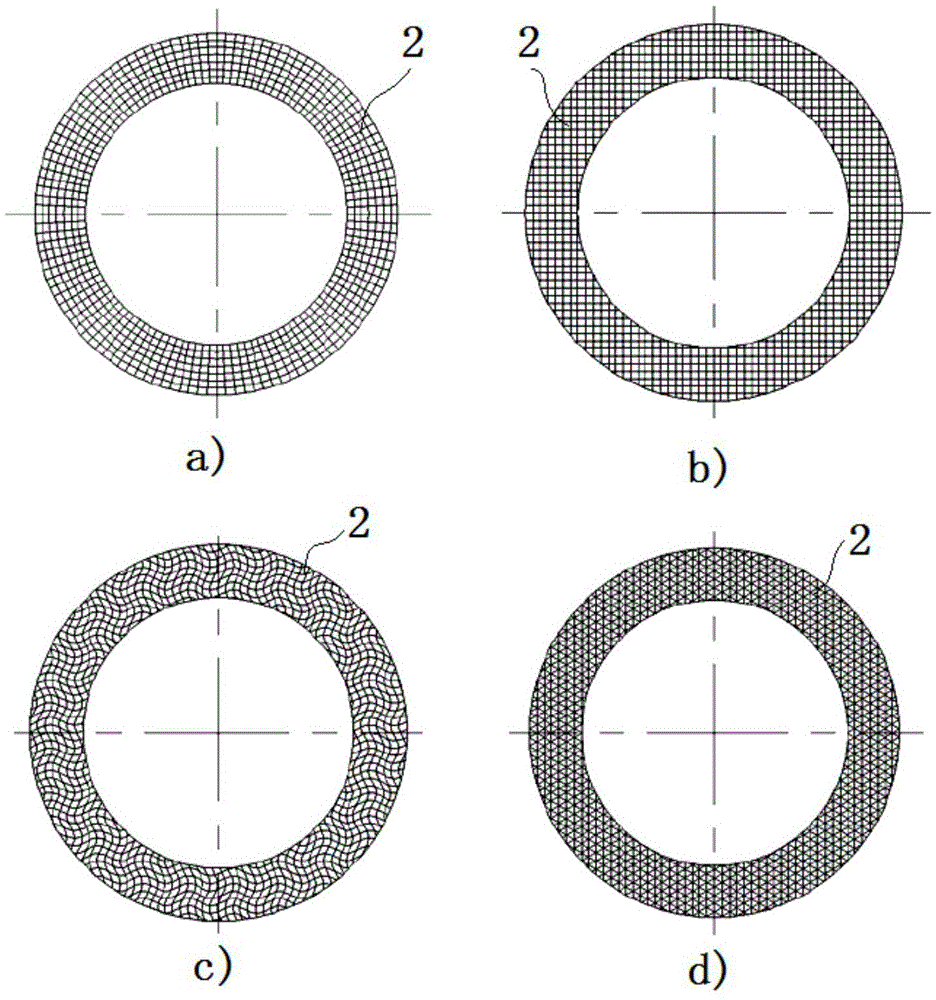

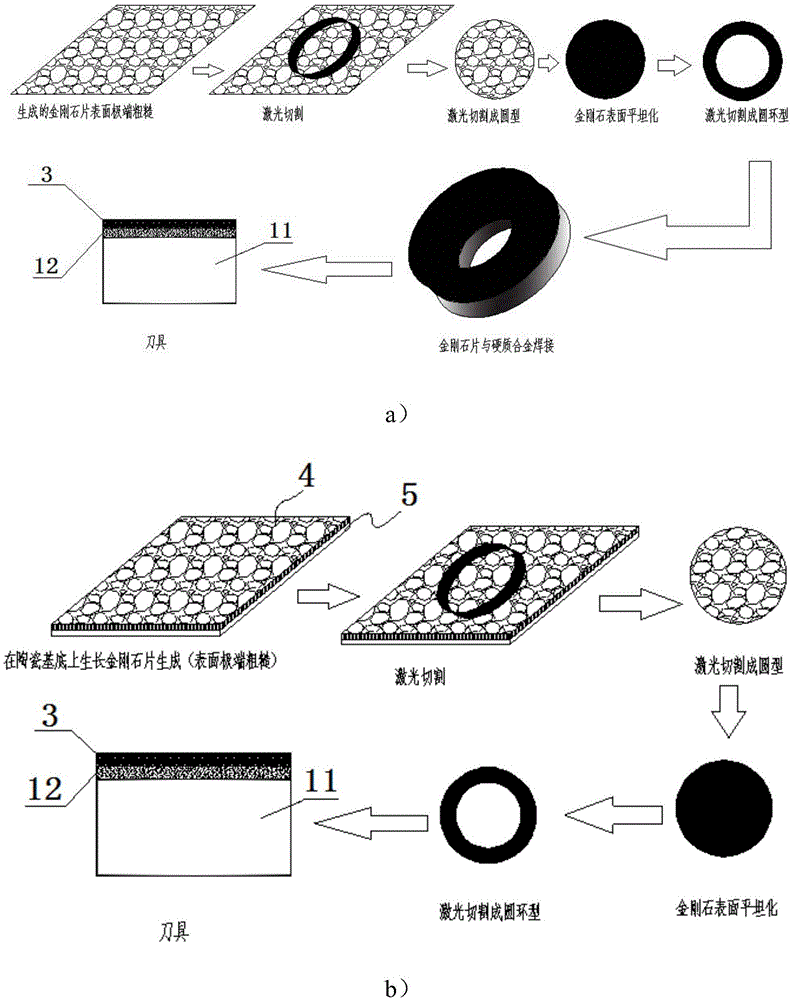

[0031] A bond-free superhard diamond grinding wheel, such as figure 1 As shown, the structure of the grinding wheel of the present invention is basically similar to that of the cup-type grinding wheel, and consists of two parts: a matrix and an abrasive layer. However, due to the poor wettability between diamond and the metal substrate, it is first necessary to vacuum-braze the polycrystalline CVD diamond sheet to the hard alloy, and then glue it to the aluminum substrate. figure 1 The inner and outer diameters of the abrasive layer shown in are 30mm and 38mm, respectively, and the thickness is 2mm. figure 2 It is a schematic diagram of the microstructure of the grinding wheel surface. The schematic diagram of the working surface of the abrasive layer in four structural forms is given in the figure, which are involute, square, rhombus and triangle.

[0032] The following compares the surface structure of the bond-free superhard diamond grinding wheel and the traditional grin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com