Resin grinding wheel for steel rail cutting and manufacturing method of resin grinding wheel

A technology for resin grinding wheels and rails, which is applied in the direction of bonded grinding wheels, manufacturing tools, abrasives, etc., can solve the problems of fast consumption of grinding edges, low removal efficiency of rail materials, high grinding heat, etc., to achieve improved bonding strength and Structural strength, improvement of self-sharpening and cutting efficiency, effects of improving toughness and structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

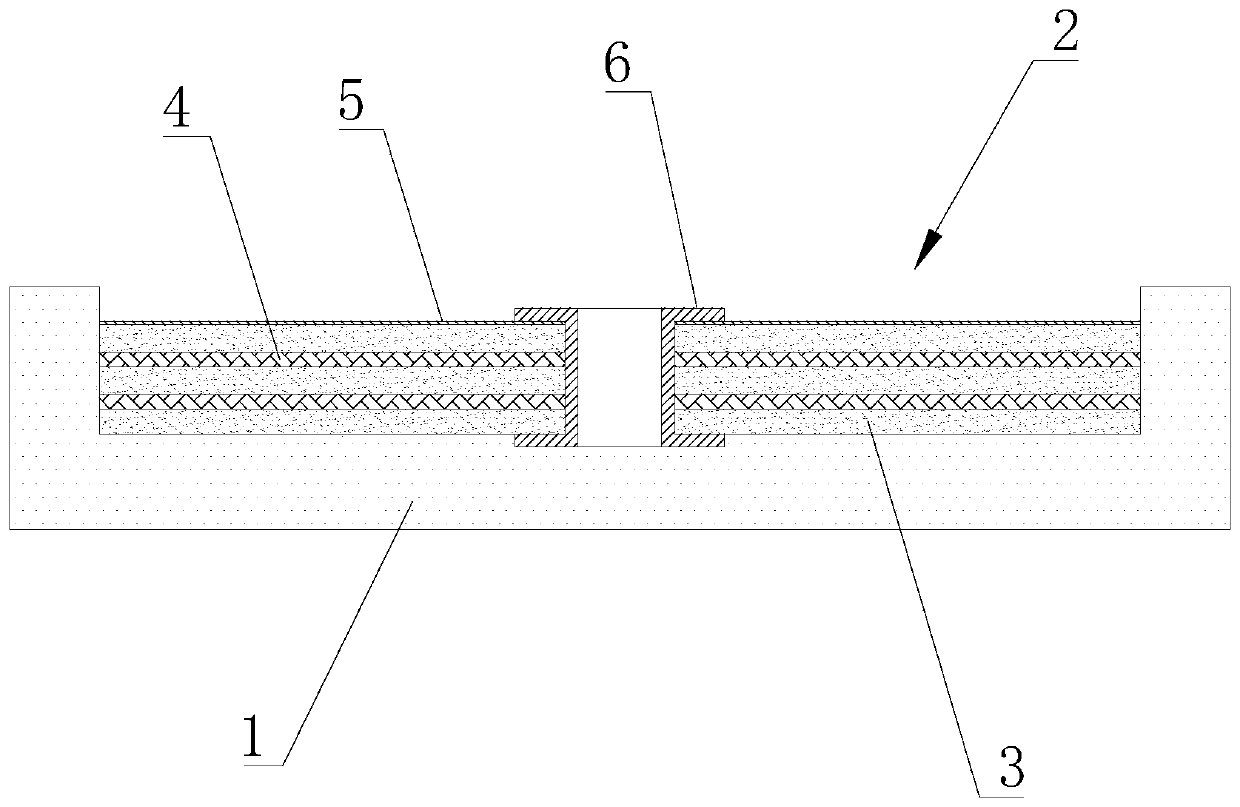

Image

Examples

Embodiment 1

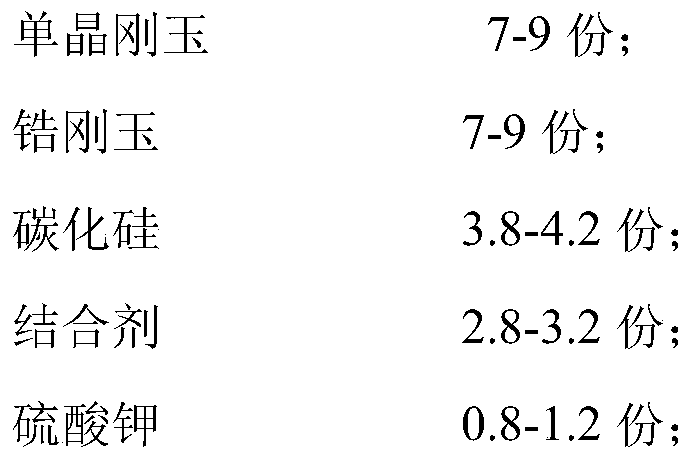

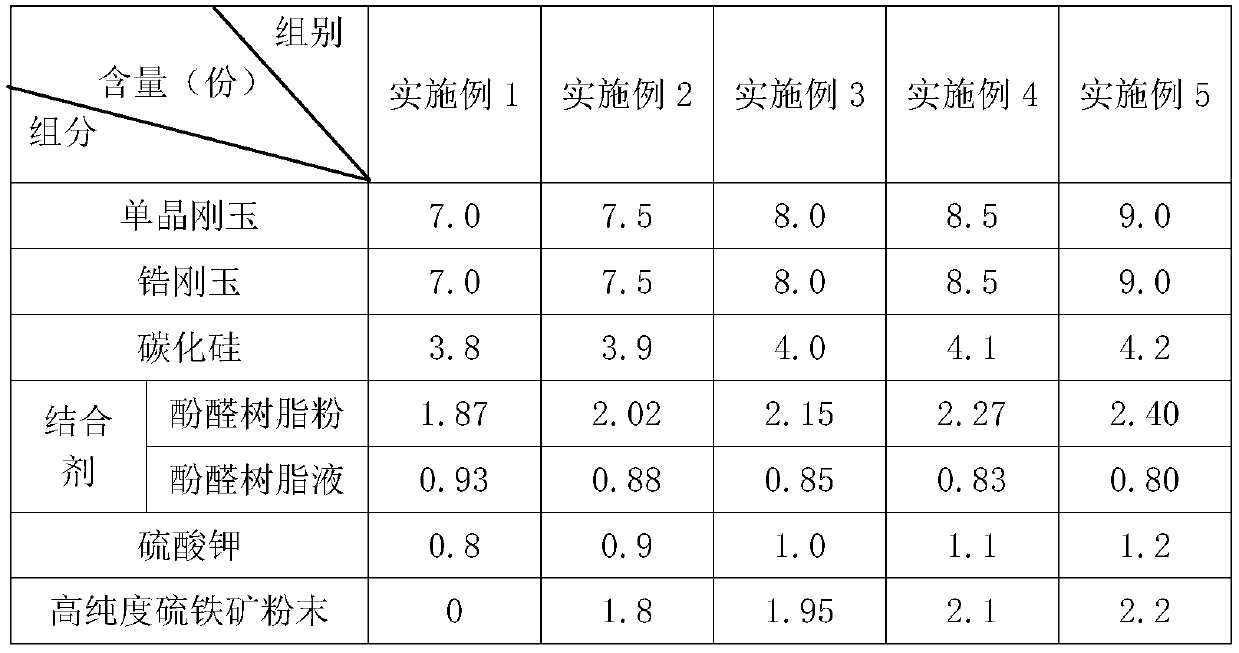

[0044] Embodiment 1: A resin grinding wheel for rail cutting, the formulation components and their contents are shown in Table 1 (1 part by weight=5kg). Wherein the phenolic resin powder is a thermoplastic phenolic resin, and the phenolic resin liquid is a thermosetting phenolic resin. The preparation method of the resin grinding wheel for rail cutting includes a mixing process and a forming process, and the mixing process includes the following steps:

[0045] A1. Mixing premix: take the material according to the formula, mix and stir single crystal corundum 24#, zirconium corundum 24# and silicon carbide 24# at the same time to form an abrasive, add phenolic resin liquid to the abrasive, mix evenly to form a premix mix;

[0046] A2. Mix coarse sand material: Potassium sulfate, high-purity pyrite powder and phenolic resin powder are mixed and stirred evenly to form a mixed powder, and the mixed material powder is mixed with the premix obtained in the A1 step, and mixed evenl...

Embodiment 2

[0052] Embodiment 2: A resin grinding wheel for rail cutting. The difference between this embodiment and Embodiment 1 lies in that the content of the formula components is different and the process parameters in the preparation method are different. The specific component contents of the formula of this embodiment are shown in Table 1, and the process parameters in the preparation method are shown in Table 3.

Embodiment 3

[0053] Embodiment 3: A resin grinding wheel for rail cutting. The difference between this embodiment and Embodiment 1 lies in that the content of the formula components is different and the process parameters in the preparation method are different. The specific component contents of the formula of this embodiment are shown in Table 1, and the process parameters in the preparation method are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com