Cup grinding wheel-electric spark composite trimmer for superhard abrasive grinding wheel

A cup-shaped grinding wheel, super-hard abrasive technology, applied in abrasive surface adjustment devices, parts of grinding machine tools, grinding/polishing equipment, etc. Achieve uniform dressing force, reduce grinding force and improve dressing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

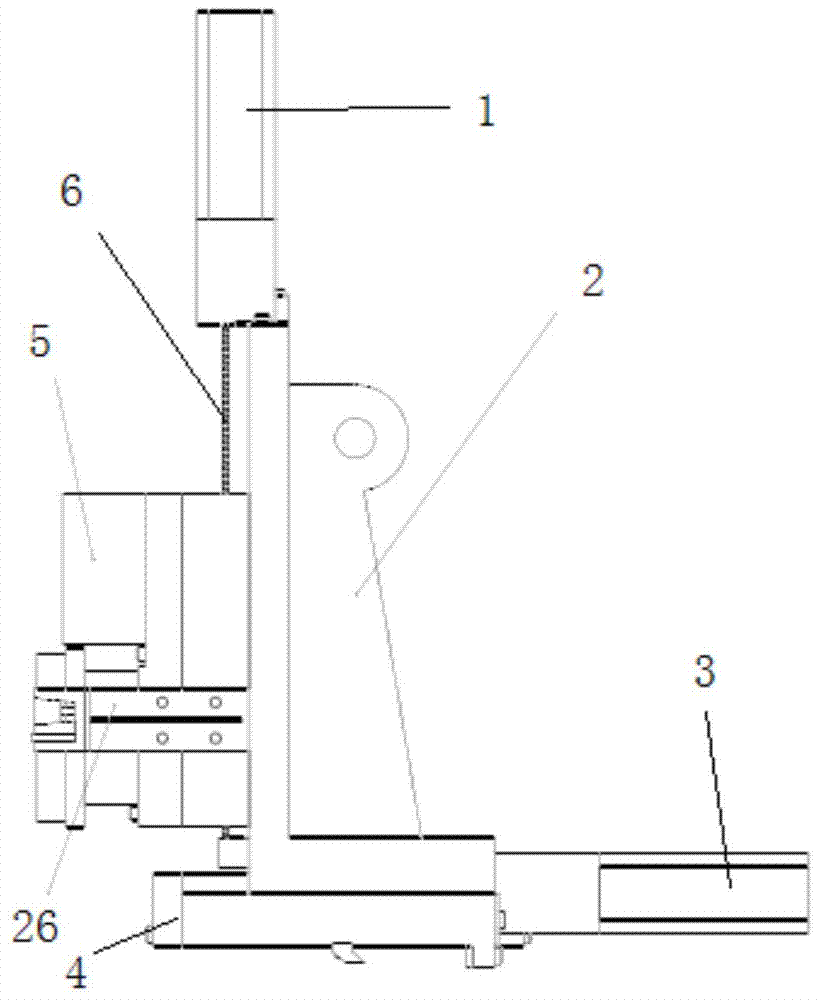

[0044] Depend on figure 1 and Figure 4 It can be seen that a cup-shaped grinding wheel-electric spark composite dressing device for cylindrical grinding superabrasive grinding wheel includes a base 4, a Y-axis feed mechanism, a Z-axis feed mechanism, a dresser 5, a grinding wheel profile detection platform 26 and a control system; Wherein, the Z-axis feeding mechanism is installed above the base 4, the Y-axis feeding mechanism is installed above the Z-axis feeding mechanism, and the dresser 5 and the grinding wheel profile detection platform 26 are installed on the Y-axis feeding mechanism. On the feeding mechanism, the grinding wheel profile detection platform 26 is installed on the side of the dresser 5, and the control system is respectively connected with the Z-axis feed mechanism, the Y-axis feed mechanism and the dresser 5; the dresser 5 is a cup-shaped grinding wheel- EDM composite trimmer.

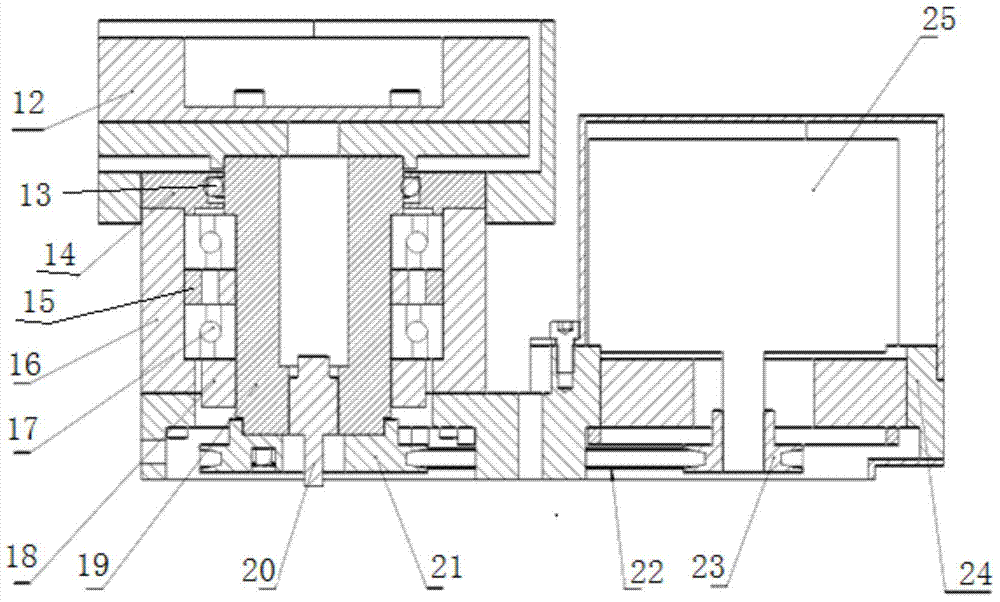

[0045] Such as figure 2 It can be seen that the cup-shaped grinding wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com