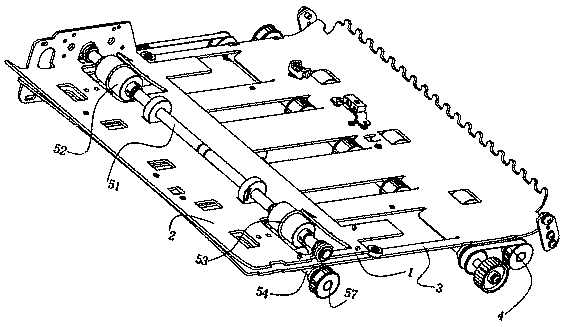

Bill trimming mechanism

A bill and edge trimming technology, applied in the direction of object supply, metal processing, pile separation, etc., can solve the problems of difficult automatic splitting of equipment, unstable state, not much, etc., achieve good market application value, improve edge trimming ability, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0030] Embodiment 2, on the basis of Embodiment 1, the right cutter group 7 includes a right belt frame 71, a secondary conveying group 72, a main conveying group 2 73, a lower conveying belt 74 and a lower cutter shaft 75, the main conveying group The second 73 and the secondary conveying group 72 respectively pass through the main belt rotating shaft one and the secondary belt rotating shaft 78 to pass through the rear side and the front side of the right belt frame 71, and pass the lower conveying belt 74 from the conveying group two 72 and the main conveying group two 73 Connected, and the two ends of the lower cutter rotating shaft 75 between the secondary conveying group 72 and the main conveying group 73 are installed on the right belt frame 71 through the bearing two shafts, and the outer wall middle part of the lower cutter rotating shaft 75 is sleeved with a right Circular cutter 76, the top of right circular cutter 76 and the bottom of upper circular cutter 65 disloc...

Embodiment 3

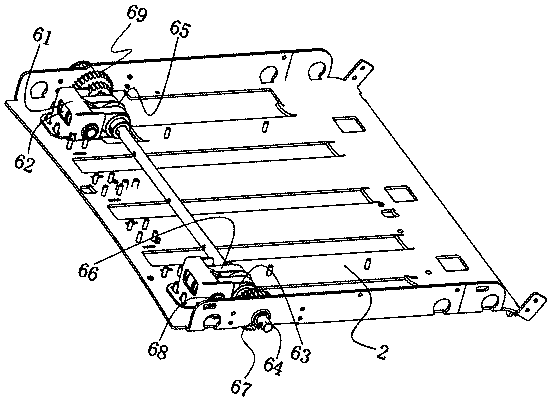

[0031] Embodiment 3, on the basis of Embodiment 2, a square through hole 2 is also opened on the lower channel plate at a position corresponding to the conveying group 2 72, through which the lower conveying belt 74 and the lower right circular cutter 76 pass through. The second square through hole protrudes upwards; the upper conveying belt 66 and the lower conveying belt 74 are in contact with each other for clamping and conveying bills, and the lower end of the upper circular cutter 65 on the right and the upper end of the right circular cutter 76 are in dislocation contact to align the bills. Carry out edge trimming operation on the right side, the upper end of the left circular cutter 65 of the upper circular cutter 65 of the left side and the upper end of the left circular cutter in the left cutter group dislocation contacts to carry out edge trimming operation to the bill left side.

Embodiment 4

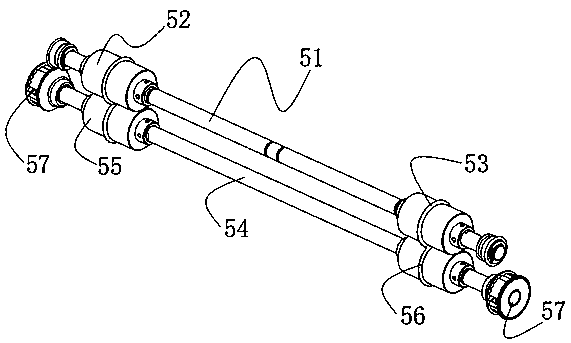

[0032] Embodiment 4, on the basis of Embodiment 2, the rotating drive assembly 8 includes a motor mounting base, a driving motor 81, a driving main pulley 82, a driving slave pulley 83 and a driving belt, and the fixed end of the driving motor 81 is fixed on the motor mounting base. The top of right belt holder 71, the working end of driving motor 81 is fixedly connected with the center of driving main pulley 82, and driving main pulley 82 is connected with driving belt pulley 83 on the upper cutter rotating shaft 64 right-hand sides by the driving belt, and driving from pulling pulley 83 And upper main gear 69 are all sleeved on the same side of the outer wall of upper cutter rotating shaft 64, and driving motor 81 works to drive main pulley 82 to drive main pulley 82 to drive driven by driving belt from pulley 83 and upper main gear 69 so as to realize synchronous rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com