Grinding wheel for grinding air valve and method for grinding air valve

A grinding wheel grinding and valve technology, used in bonded grinding wheels, abrasives, metal processing equipment, etc., can solve problems such as difficulty in meeting high-end engines for valve disc thickness processing accuracy requirements, poor processing dimensional consistency, and low processing efficiency. The grinding process is safe and reliable, the grinding wheel durability is high, and the grinding quality is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

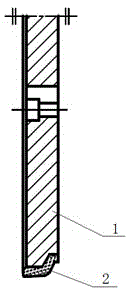

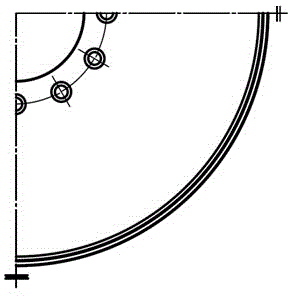

[0027] Such as figure 1 , figure 2 As shown, the grinding wheel used for grinding the valve is a CBN grinding wheel, which includes a steel substrate 1 and a CBN abrasive layer 2 coated on the steel substrate.

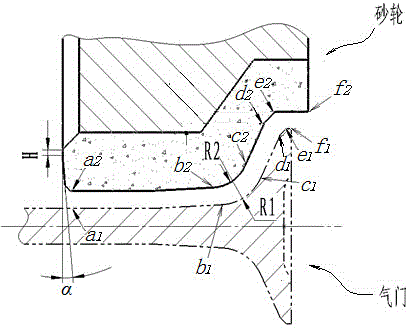

[0028] Such as image 3 As shown, the grinding wheel has an outer contour line adapted to the outer contour of the valve along the axial direction, and the outer contour line of the grinding wheel consists of the first line segment e2f2 corresponding to the outer circle contour line segment e1f1 of the valve disc, and the outer cone surface contour line segment d1e1 of the valve disc The corresponding second line segment d2e2, the third line segment c2d2 corresponding to the valve disc inner cone contour line segment c1d1, the arc line segment b2c2 corresponding to the valve neck arc contour line segment b1c1 and the fourth line segment corresponding to the valve neck contour line segment a1b1 The line segment a2b2 is connected, the radius R2 of the arc line segment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com