Diamond grinding wheel with micro structure and manufacturing method for diamond grinding wheel

A diamond grinding wheel and microstructure technology, which is applied in the field of diamond grinding wheels, can solve problems such as inconsistent heights of cutting edges, affect the surface quality of workpieces, reduce grinding efficiency, etc., and achieve superior grinding performance, good wear resistance, and manufacturing accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

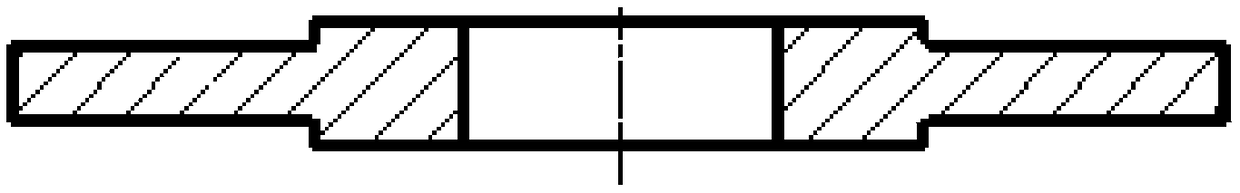

[0037] Embodiment 1: A diamond grinding wheel with a microstructure described in this embodiment includes a SiC ceramic grinding wheel substrate 1, such as figure 1 As shown, the SiC ceramic grinding wheel base 1 is a disc-shaped structure with a diameter of 50 mm to 80 mm, the diameter of the central mounting hole is 1 / 3 to 1 / 2 of the diameter of the SiC ceramic grinding wheel base 1, and the edge thickness of the SiC ceramic grinding wheel base 1 is 3 mm. ~5mm, the height of the positioning surface is 0.5mm~1mm, the outer circumference is a plane or a convex arc surface (that is, the edge of the axial section of the SiC ceramic grinding wheel base 1 is linear or arc-shaped), and the roundness error of the outer circumference is less than 1 μm , the surface shape error of the outer circular contour is less than 1 μm, the flatness of the positioning surface is less than 2 μm, and the perpendicularity between the positioning surface and the axis of the outer circular surface is ...

specific Embodiment approach 2

[0042] Specific embodiment two: the preparation method of a kind of diamond grinding wheel with microstructure described in this embodiment, concrete steps are:

[0043] Step 1: Prepare polycrystalline diamond coating.

[0044] Using chemical vapor deposition (chemical vapor deposition is a chemical technology, which mainly uses one or several gas-phase compounds or simple substances containing thin film elements to perform chemical reactions on the surface of the substrate to form a thin film) on the grinding wheel substrate 1 A polycrystalline diamond coating 2 with a thickness of 20 μm to 50 μm is formed on the outer peripheral surface.

[0045] Specifically, polycrystalline diamond coating 2 was prepared by using hot wire chemical vapor deposition method:

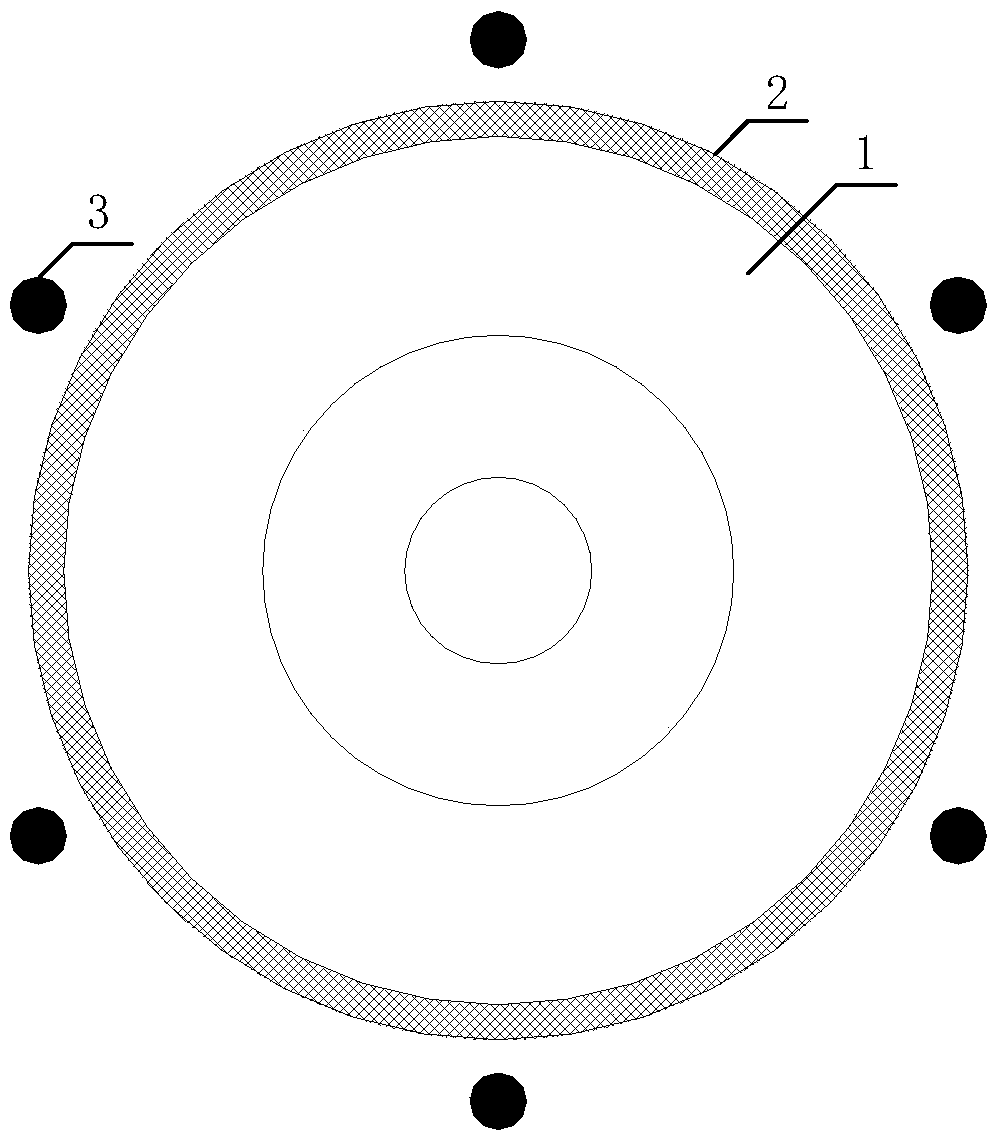

[0046] like image 3 As shown, 6 to 8 tungsten wires 3 are evenly arranged on the outer circumference of the grinding wheel base 1, and all the tungsten wires 3 are parallel to the central axis of the grinding wheel bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com