Method and device for composite vibration grinding based on ultrasonic high frequency and pneumatic low frequency

A technology of high-frequency vibration and low-frequency vibration, which is applied in the field of coating material cutting processing technology and coating processing equipment components, can solve the problems of limiting the range of vibration processing, reduce processing costs, ensure device safety, and high processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings.

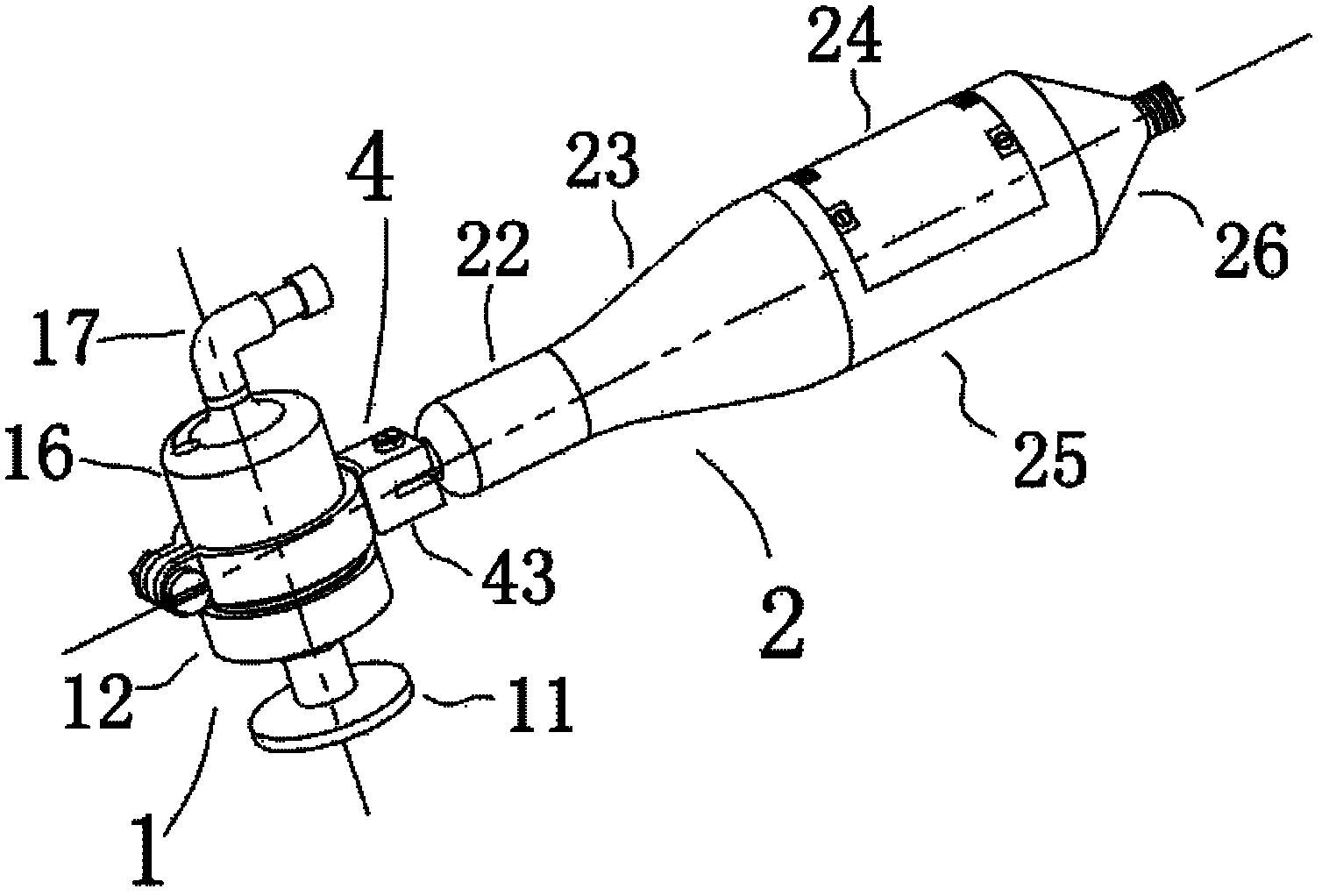

[0039] See figure 1 As shown, the present invention is a device based on ultrasonic high-frequency pneumatic low-frequency compound vibration grinding. The position connection relationship between them is: the low-frequency vibration excitation component 3 is installed in the low-frequency vibration shell component 2 to form the low-frequency vibration component, and the ultrasonic high-frequency vibration component 1 and the low-frequency vibration component are connected through the connection component 4 .

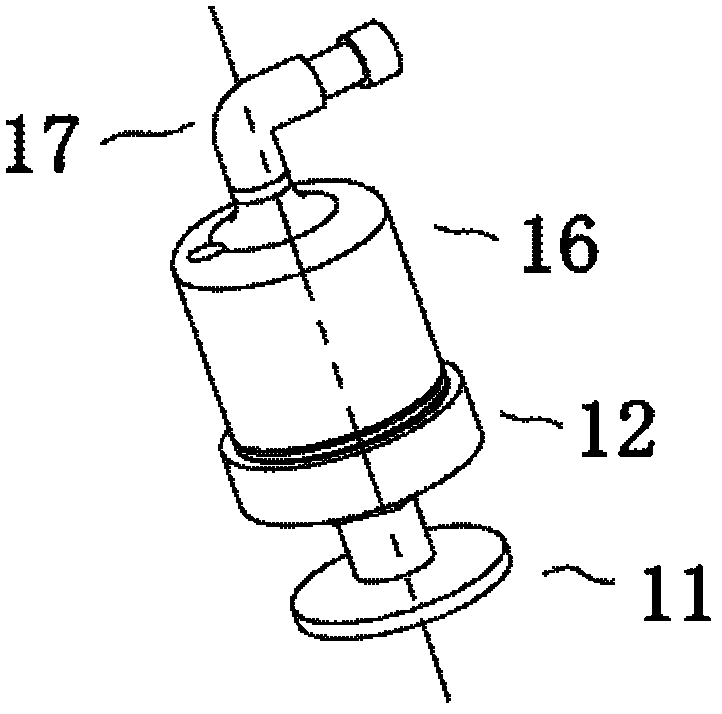

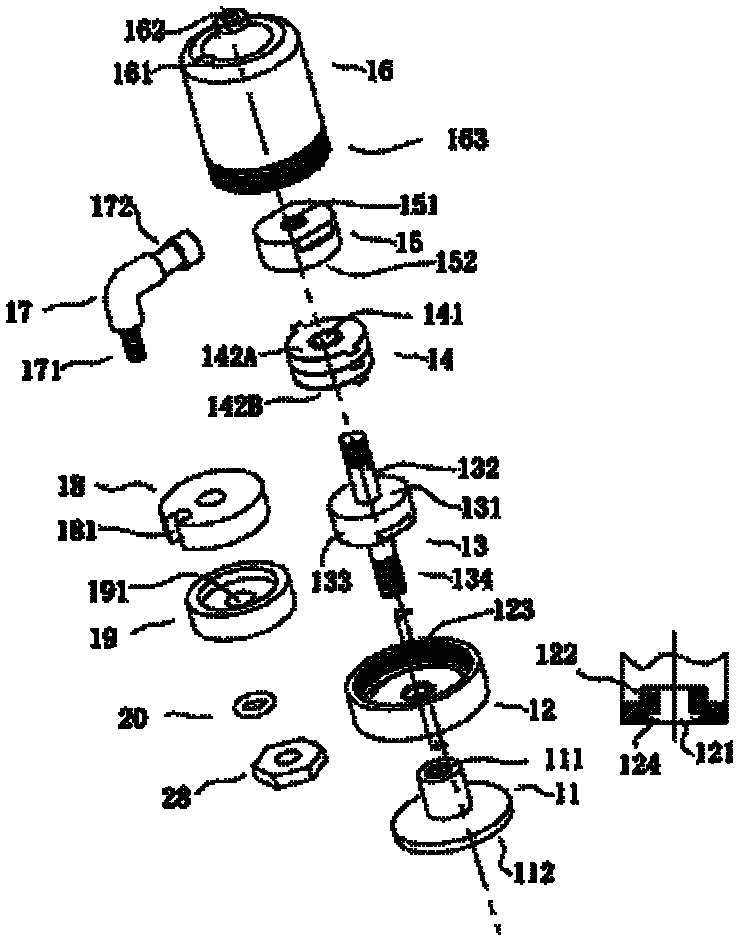

[0040] Ultrasonic high frequency vibration components 1 see figure 2 , image 3 , including a tray 11, a compression cover 12, a horn 13, a high-frequency vibration excitation source 14, a rear cover 15, a housing 16, a corner 17, a rear vibration isolation block 18, a front vibration isolation block 19, a sealing ring 20, Position adjusting nut 28...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com