Processing method of straws and manufacturing method of straw fiber plate

A processing method and straw fiber technology are applied in the field of straw fiber board manufacturing, which can solve the problems of reducing strength, increasing production processes, and not producing sufficient cohesion, and achieving the effects of improving gluing performance, increasing strength, and reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

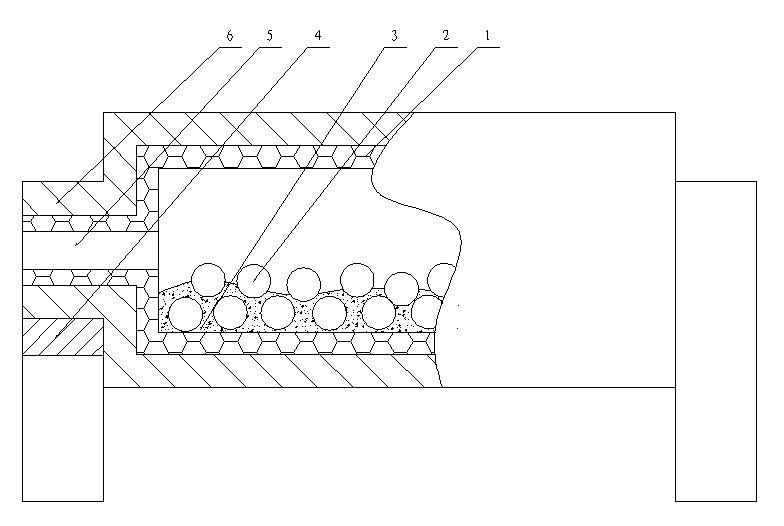

Image

Examples

Embodiment 1

[0029] A processing method for stalks, its steps are as follows:

[0030] (1) Cut the freshly harvested wheat straw into 5-15mm sections, remove broken leaves and sediment impurities, and then remove iron through a magnetic drum, and use the existing brick making machine to press straw blocks with a length of 5-10cm in width and height. Compact the straw blocks, the density of the straw blocks is 0.65-0.75 g / cubic centimeter, the purpose of beating the straw into straw blocks is to prevent fire;

[0031] (2) Microwave irradiation is carried out on the straw block, the microwave frequency is 15GHz, and the power intensity is 50W / cm 2 , the time is 0.05s, put the straw blocks neatly on the microwave irradiation conveyor belt, the straw hairs protruding from the straw blocks can burn and cause flames during irradiation, and the straw blocks will not catch fire. Set up a sprinkler head, and the straw blocks that have just started to ignite will be extinguished by water, and a fir...

Embodiment 2

[0040] A processing method for stalks, its steps are as follows:

[0041] (1) Cut the freshly harvested wheat straw into 5-15mm sections, remove broken leaves and sediment impurities, and then remove iron through a magnetic drum, and use the existing brick making machine to press straw blocks with a length of 5-10cm in width and height. Compact the straw blocks, the density of the straw blocks is 0.65-0.75 g / cubic centimeter, the purpose of beating the straw into straw blocks is to prevent fire;

[0042] (2) Microwave irradiation is carried out on the straw blocks, the microwave frequency is 15-20GHz, and the power intensity is 100W / cm 2 , the time is 0.05-50s, and microwave irradiation can be carried out in batches, the time is 0.05-2.5s / time, and the frequency is 1-10 times. Put the straw blocks neatly on the microwave irradiation conveyor belt. The protruding straw hairs can burn and cause flames, and the straw blocks will not catch fire. A sprinkler head is installed on t...

Embodiment 3

[0050] A processing method for stalks, its steps are as follows:

[0051] (1) Cut the freshly harvested wheat straw into 5-15mm sections, remove broken leaves and sediment impurities, and then remove iron through a magnetic drum, and use the existing brick making machine to press straw blocks with a length of 5-10cm in width and height. Compact the straw blocks, the density of the straw blocks is 0.65-0.75 g / cubic centimeter, the purpose of beating the straw into straw blocks is to prevent fire;

[0052] (2) Microwave irradiation is carried out on the straw blocks, the microwave frequency is 15-20GHz, and the power intensity is 50-100W / cm 2 , the time is 25s, microwave irradiation can be carried out in batches, the time is 2.5s / time, and the frequency is 10 times. Put the straw blocks neatly on the microwave irradiation conveyor belt. Burning will cause flames, and the straw blocks will not catch fire. A sprinkler head is installed on the side of the irradiation instrument, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com