Method for evaluating damage of grinding surface of advanced ceramics based on wavelet multi-scale analysis

A multi-scale analysis and surface damage technology, applied in the direction of material inspection products, etc., can solve the problems that the time-frequency localization characteristics of surface contour signals cannot be finely described and cannot reflect the essential characteristics, so as to achieve accurate extraction and evaluation, and operability Strong, easy-to-step effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The method for evaluating surface damage of advanced ceramic grinding based on wavelet multi-scale analysis of the present invention will be described in detail below in conjunction with the embodiments and drawings.

[0048] The evaluation method of advanced ceramic grinding surface damage based on wavelet multi-scale analysis of the present invention comprises the following steps:

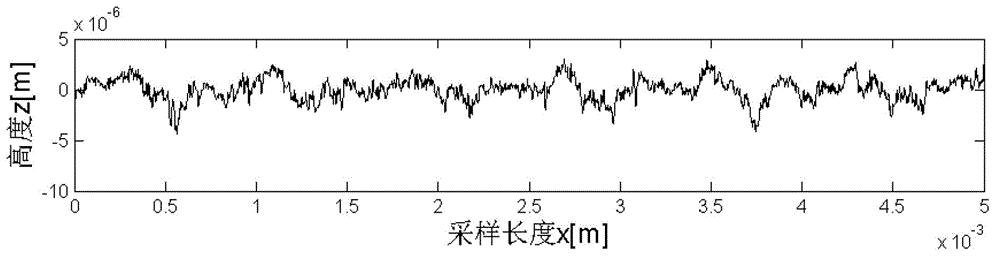

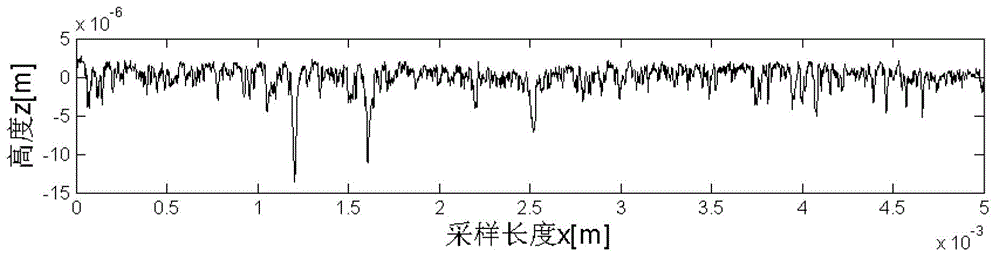

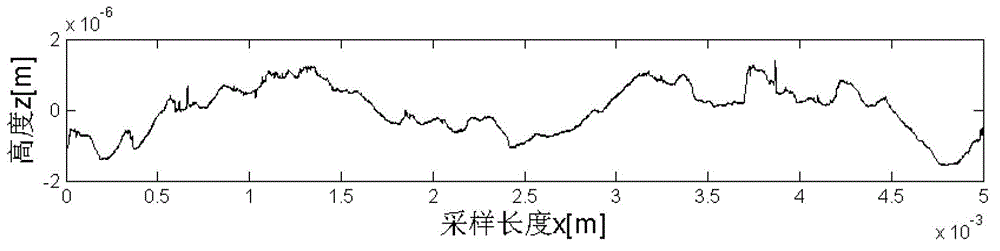

[0049] 1) Collect the original profile data of the sample, and select the best wavelet base based on the mathematical characteristics of the wavelet base and the principle of minimizing the reconstruction error of the grinding surface of engineering ceramics.

[0050] The collection of original profile data of the sample is to use a roughness profiler to measure the grinding surface of the sample along the grinding direction, and then export the original data of the surface profile through the data processing software that comes with the instrument after measurement.

[0051] The selection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com