Floating seal ring with composite working face

A technology of working face and floating seal ring, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of high cost and low productivity, and achieve the effects of high productivity, improved service life, and improved wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

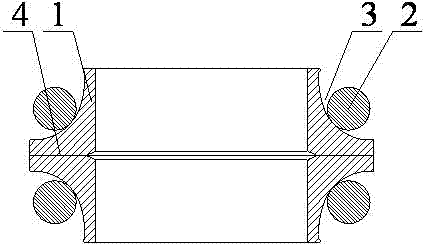

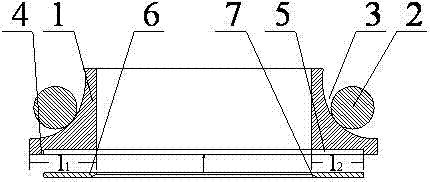

[0030] like image 3As shown, the composite working face floating seal ring of this embodiment includes a pair of sealing ring bodies 1 with symmetrical upper and lower structures, the sealing ring body 1 is made of cast iron, and a ring is provided on the outside of the sealing ring body 1 for The groove 3 of the sealing ring 2 is arranged, and the sealing ring 2 is arranged in the groove. The working surface 4 of the sealing ring body 1 is provided with a wear-resistant belt fitting groove 5, and the wear-resistant belt fitting groove 5 has a width 1 2 Occupy the total width of the working face l 1 75% of the wear-resistant band, a ring of wear-resistant band 6 is fixedly assembled in the wear-resistant band assembling groove 5 . The wear-resistant belt assembling groove 5 is opened on the inner edge of the working surface 4 . The wear-resistant belt 6 is made of alumina ceramic powder with an alumina content of 75% and an original grain size of 0.5 μm. After dry pressing...

Embodiment 2

[0033] like Figure 4 As shown, the composite working face floating seal ring of this embodiment includes a pair of sealing ring bodies 1 with symmetrical upper and lower structures, the sealing ring body 1 is made of cast iron, and a ring is provided on the outside of the sealing ring body 1 for The groove 3 of the sealing ring 2 is arranged, and the sealing ring 2 is arranged in the groove. The working surface 4 of the sealing ring body 1 is provided with a wear-resistant belt fitting groove 5, and the wear-resistant belt fitting groove 5 has a width 1 2 Occupy the total width of the working face l 1 60% of the wear-resistant band, a ring of wear-resistant band 6 is fixedly assembled in the wear-resistant band assembling groove 5 . The wear-resistant belt assembling groove 5 is opened at the inner side of the working surface 4 . The wear-resistant belt 6 is made of zirconia ceramic powder with a zirconia content of 80% and an original grain size of 0.5 μm. After dry press...

Embodiment 3

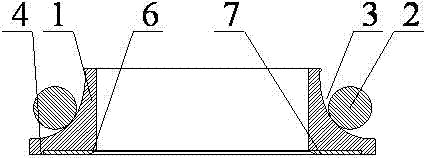

[0036] like Figure 5 As shown, the composite working face floating seal ring of this embodiment includes a pair of sealing ring bodies 1 with symmetrical upper and lower structures, the sealing ring body 1 is made of cast iron, and a ring is provided on the outside of the sealing ring body 1 for The groove 3 of the sealing ring 2 is arranged, and the sealing ring 2 is arranged in the groove. The working surface 4 of the sealing ring body 1 is provided with a wear-resistant belt fitting groove 5, and the wear-resistant belt fitting groove 5 has a width 1 2 Occupy the total width of the working face l 1 25% of the wear-resistant band, a ring of wear-resistant band 6 is fixedly assembled in the wear-resistant band assembling groove 5 . The wear-resistant belt assembling groove 5 is opened at the outer side of the working surface 4 . The wear-resistant belt 6 is made of silicon carbide ceramic powder with a silicon carbide content of 90% and an original grain size of 1 μm. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com