Prestress grinding processing method of ceramic material

A ceramic material, grinding technology, used in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve the problems of crushing and cracking, low surface roughness, etc., to increase grinding depth and reduce processing costs , the effect of improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

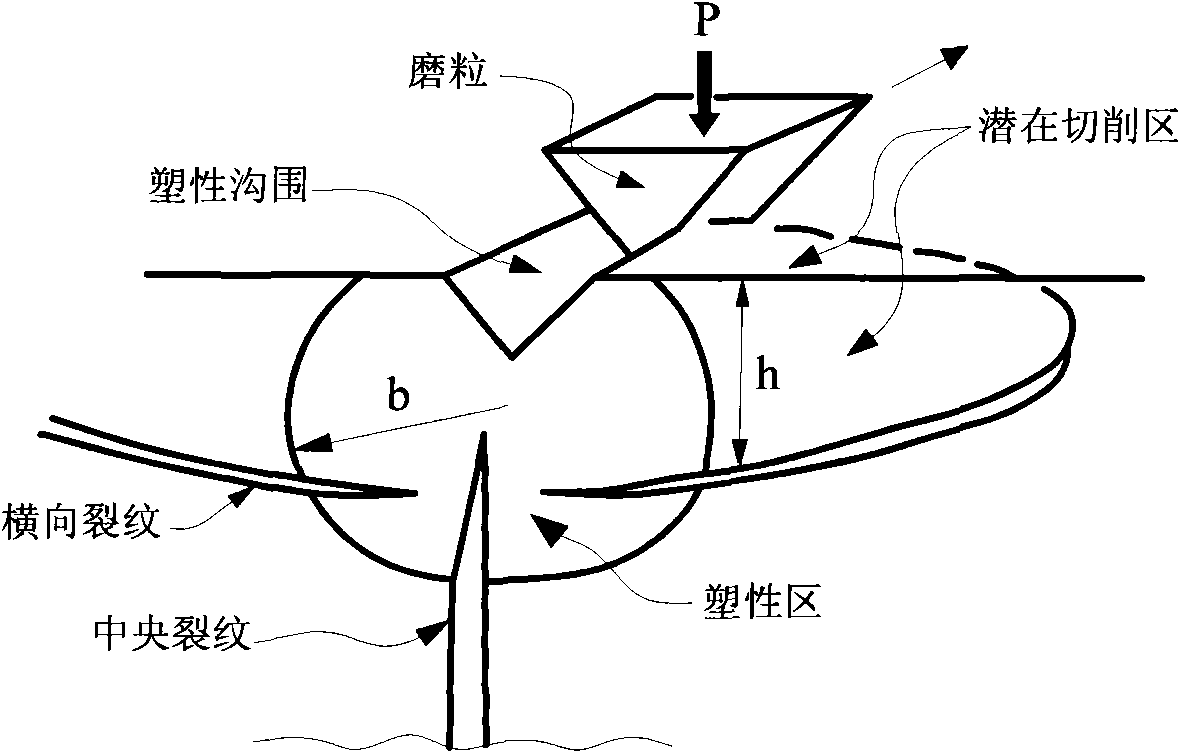

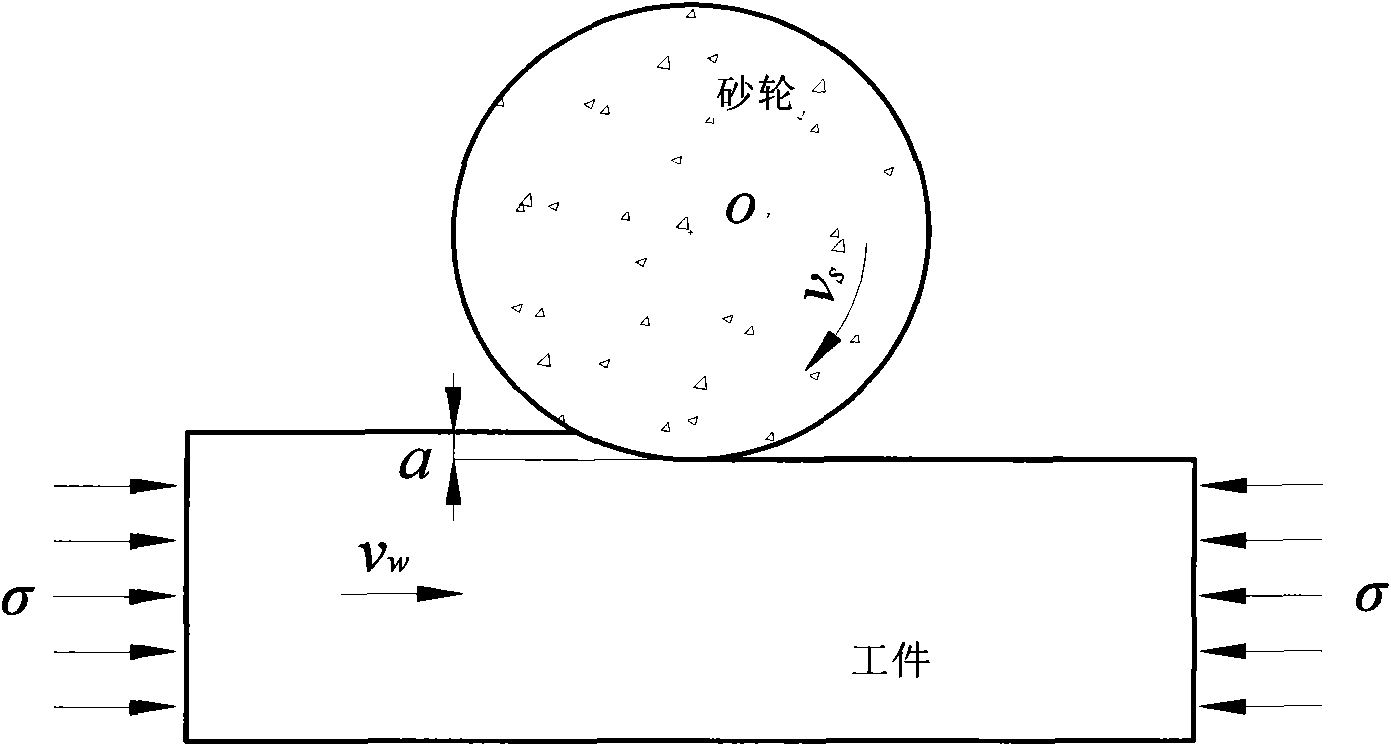

[0012] The main principle of the present invention is: taking indentation fracture mechanics and elastoplastic mechanics as the theoretical basis, its schematic diagram is as attached figure 1 shown. Two types of crack systems generated during the grinding process of ceramic materials are analyzed: median cracks and transverse cracks. Among them, the median crack extends to the bottom of the material surface and remains inside the processed ceramic workpiece; the transverse crack will expand to the material surface with the removal of the normal load to form the removal of material. By applying prestress to the processed ceramic parts, the law of crack propagation has changed accordingly. Within the strength range of the ceramic material, as the prestress increases, cracks are not easy to propagate along the bottom of the material, but extend into lateral cracks along both sides of the material to remove the material; and the greater the prestress, the lateral cracks propagat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com