Gel injection molding method of engineering ceramic

A technology of gel injection molding and engineering ceramics, which is applied in the field of engineering ceramics gel injection molding, can solve the problems of low strength of engineering ceramics dry green bodies, affecting the quality of engineering ceramic bodies, and low room temperature bending strength, etc., to achieve The molding process is easy to control, the production cost is low, and the production efficiency is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

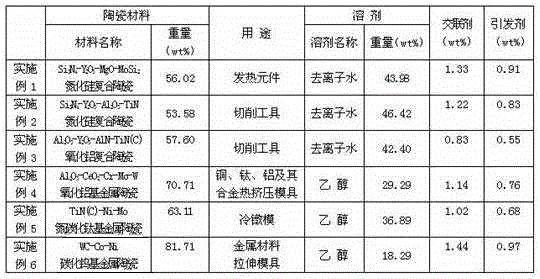

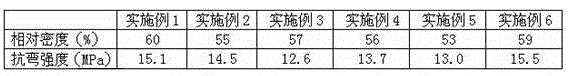

[0018] Examples 1-6 See Table 1 for the cross-linking agent (Carbomer 934P), initiator (triethanolamine), and solvent ratios added to the gel injection molding of different types of engineering ceramic materials.

[0019] Table 1

[0020]

[0021] Note: The sum of the weight percentage of ceramic material and solvent in Table 1 is 100wt%; The percentage by weight of the total weight of ceramic powder.

[0022] Specific steps are as follows:

[0023] (1) Weigh the mixed engineering ceramic powder and carbomer (cross-linked polyacrylic resin) according to the weight percentage distribution ratio in Table 1, and obtain a suspended and stable slurry for 4 hours;

[0024] (2) Add the initiator to the slurry obtained in step (1) according to the weight percentage ratio described in Table 1, and after ball milling for 8 minutes, vacuum defoaming for 7 minutes;

[0025] (3) Inject into the mold and form in situ solidified colloidal state, dry at room temperature for 17 hours, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com