Method for prefabricating straight through crack and dedicated device therefor

A special device and crack technology, applied in the preparation of test samples, etc., can solve the problems of difficult control of crack length and shape, huge cost and time, etc., to achieve easy sample preparation, prevent instability and fracture, and simple experimental methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

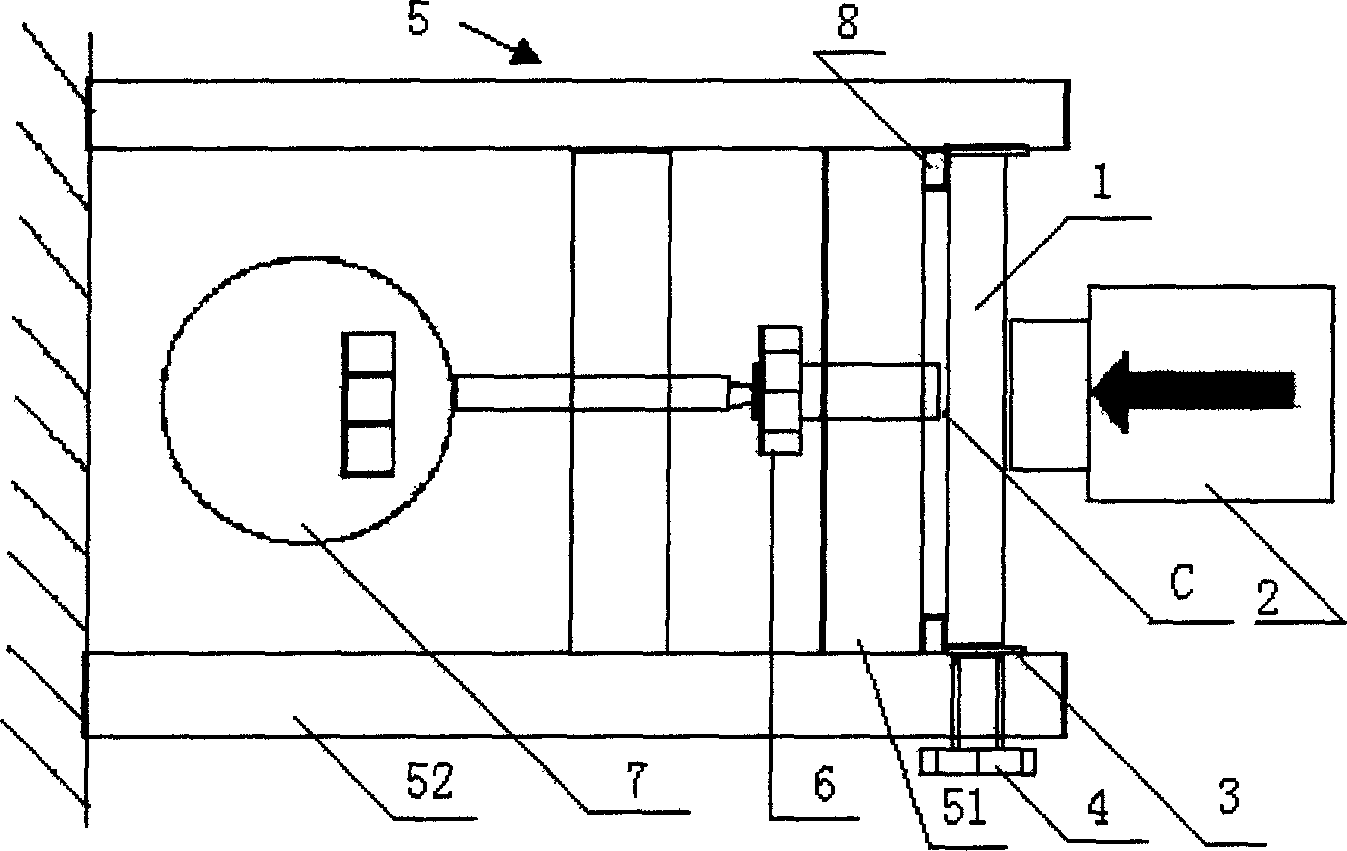

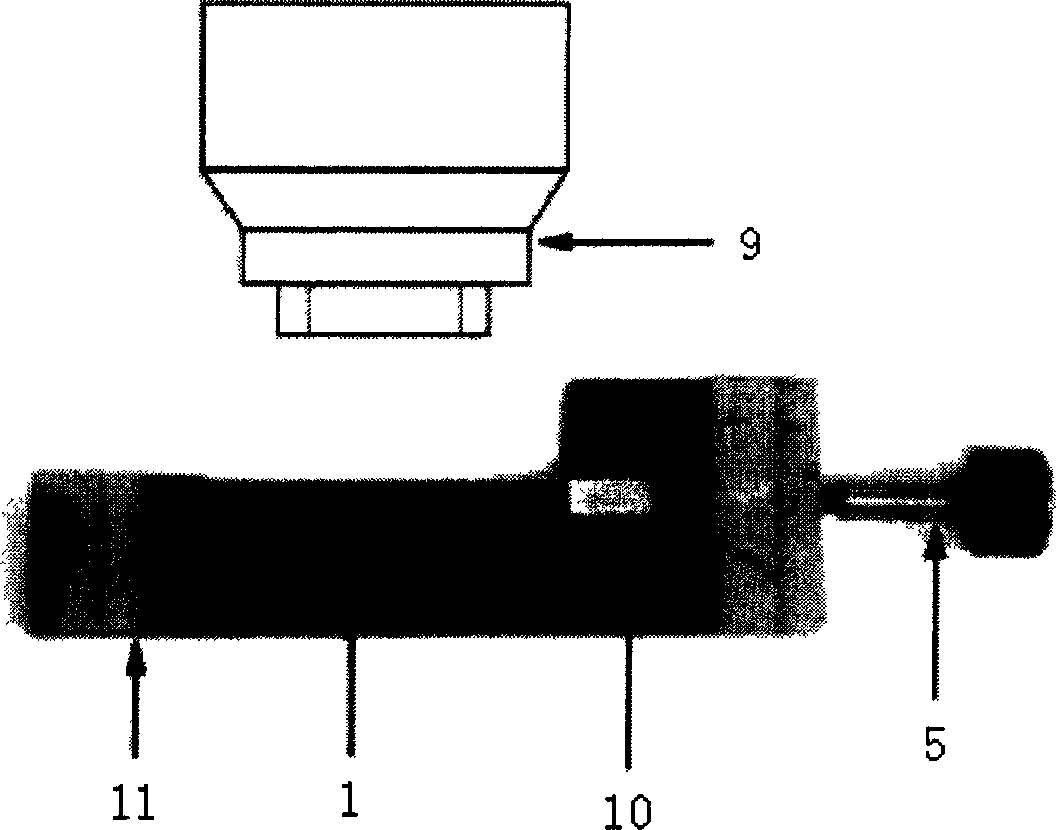

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Crack initiation of titanium silicon carbon / silicon carbide composite ceramic samples

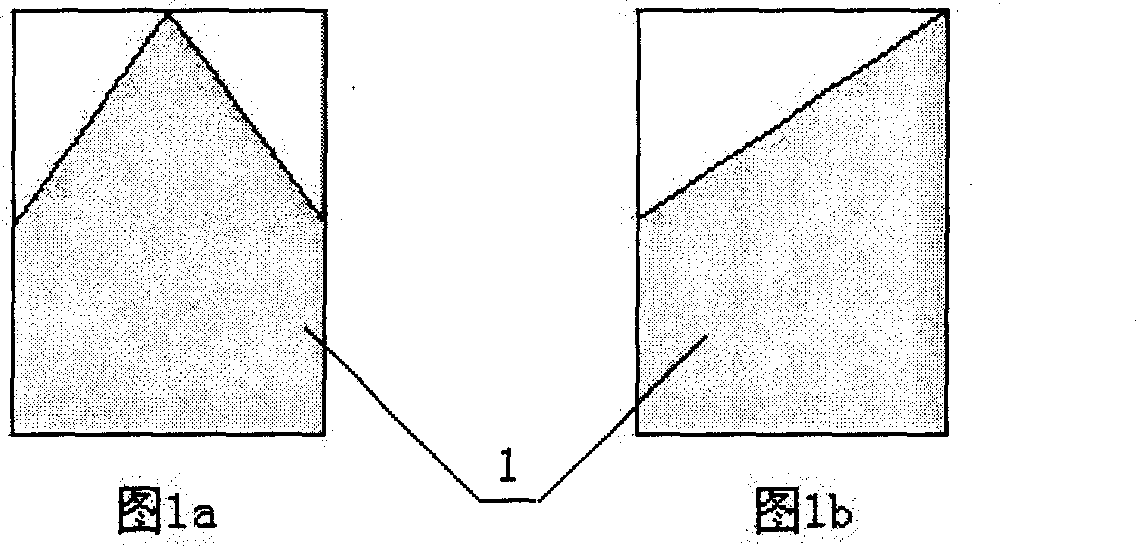

[0030] Processing titanium silicon carbon / silicon carbide composite ceramics to 3×4mm 2 For a sample with a cross-section and a length of 36 mm, cut a triangular incision in the center with a diamond circular slicer after polishing, conduct crack initiation and monitoring on the sample according to the above-mentioned implementation method, and use a camera to photograph the crack propagation process. About half of the sample width stops loading, and finally a prefabricated crack with the same crack width as the natural crack is obtained. The crack growth process is shown in Fig. 5(a-e).

Embodiment 2

[0031] Embodiment 2: Crack initiation and fracture toughness test of titanium silicon carbon ceramic sample

[0032] Processing titanium silicon carbon ceramics to 4×8mm 2 and 3×4mm 2 For a sample with a cross-section and a length of 36 mm, after polishing, cut a triangular incision and a mountain-shaped incision in the center of the sample with a diamond circular slicer for different samples, and conduct crack initiation and monitoring on the sample according to the above-mentioned implementation method, and use The camera photographs the crack growth process, and the loading is stopped when the crack reaches about half the width of the sample, and finally a prefabricated crack with the same crack width as the natural crack is obtained. The crack growth process of the sample with a triangular incision is as follows: Figure 6 shown.

[0033] The cracking process of the sample with a mountain-shaped incision is invisible under the microscope, and can only be judged by the s...

Embodiment 3

[0034] Example 3: Crack initiation of zirconia ceramic samples

[0035] Machining zirconia ceramics to 3×4mm 2 For a sample with a cross-section and a length of 30mm, cut a triangular incision in the center with a diamond circular slicer after polishing, conduct crack initiation and monitoring on the sample according to the above-mentioned implementation method, and use a camera to photograph the crack growth process to obtain a crack width The prefabricated cracks are exactly the same as the natural cracks, but the cracks are difficult to distinguish and see after unloading, and the crack growth process is as follows: Figure 9 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com