Method for machining outer circles of ceramics in squeezing manner by aid of edge cracking and horn effects

A sharp-angle effect, extrusion technology, applied in stone processing equipment, stone processing tools, metal processing equipment, etc., can solve the problems of reduced processing costs and high processing costs of hard and brittle materials, and reduce processing costs and small tool losses. , the effect of low power consumption and tool loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, the cylindrical silicon nitride ceramic outer circle processing is completed by axial low-speed feed through the rotating ceramic cylindrical tool, and it includes the following steps:

[0028] The first step: groove the surface of the ceramic workpiece. like figure 1 As shown, the ceramic workpiece is clamped on the chuck 11 of the CNC grinding machine, and the motor spindle 14 drives the (small) grinding wheel 13 with an outer diameter of 20mm to process grooves on the outer surface of the engineering ceramic 12 at a speed of 3000r / min. like figure 2 As shown, after processing, the convex part forms a symmetrical edge band 21 and a sharp corner band 22 at the bottom of the groove. The parameters of the groove are that the groove width 24 is 3 mm, the groove depth 25 is 2 mm, and the surface width 23 of the raised part is 3 mm.

[0029] The second step: if image 3 As shown, the sintered silicon nitride ceramic workpiece 32 processed in the fir...

Embodiment 2

[0033] In this embodiment, through the cemented carbide turning tool clamped on the lathe tool holder, the axial low-speed feed completes the machining of the cylindrical silicon nitride ceramic outer circle, which includes the following steps:

[0034] The first step: groove the surface of the ceramic workpiece. like figure 1 As shown, the ceramic workpiece is clamped on the CNC grinding machine chuck 11, and the motor spindle 12 drives a small grinding wheel 13 with an outer diameter of 20mm to process a groove on the outer surface of the engineering ceramic 14 at a speed of 5000r / min (such as figure 2 ), the raised parts retained after processing form symmetrical edge bands 21 and sharp corner bands 22 at the bottom of the groove. The parameters of the groove are that the groove width 24 is 1 mm, the groove depth 25 is 0.5 mm, and the surface width 23 of the raised part is 1 mm.

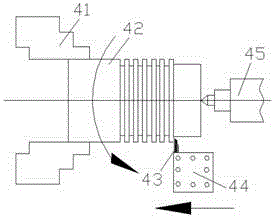

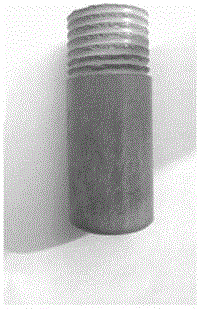

[0035] The second step: if Figure 4 As shown, the silicon nitride ceramics 42 are clamped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com