Laser-induced heat-cracking grinding method for aluminum oxide engineering ceramics

An engineering ceramics, laser-induced technology, applied in the field of grinding processing, can solve the problem of reducing the service life and working reliability of engineering ceramics parts, unable to fundamentally eliminate surface/subsurface cracks, and reducing the wear resistance of alumina engineering ceramics surfaces. and other problems, to achieve the effect of being beneficial to the surface quality, reducing the processing cost and reducing the grinding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

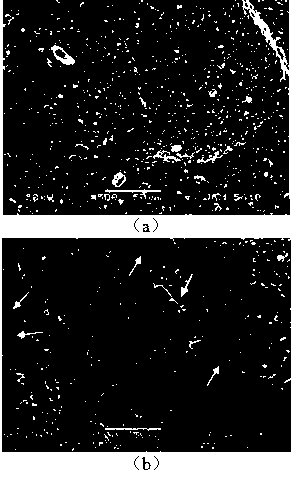

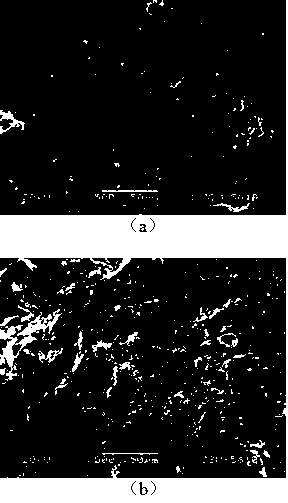

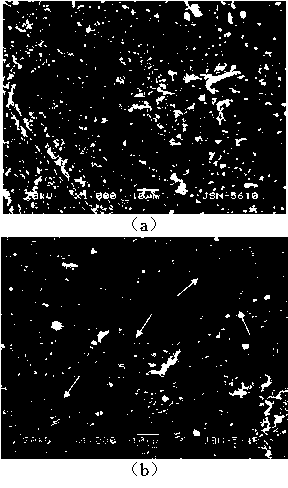

[0033] The following will be combined with Figure 1-6 The present invention is further described.

[0034] In view of the fact that cracks will reduce the wear resistance of the surface of alumina engineering ceramics, the present invention adopts a reverse thinking method and proposes a method of actively introducing thermal cracks to reduce the wear resistance of alumina engineering ceramics, that is, the laser-induced thermal cracking grinding method. The method specifically includes the following steps:

[0035] The first step is to induce thermal cracks on the surface of alumina engineering ceramics by low-power laser radiation, and reasonably control the expansion of cracks;

[0036] In the second step, the thermal crack layer on the surface of the alumina engineering ceramics is ground in a wet grinding state.

[0037] Since the properties of alumina ceramic materials have a great influence on the processing mechanism of laser-induced thermal cracking grinding, in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spot diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com