Rapid descaling device and descaling treatment method thereof

A rapid and rust-removing liquid technology is applied in the field of rust removal device and its rust removal treatment, valve rapid rust removal device and its rust removal treatment field. Achieving the effect of avoiding waste, simple overall structure and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

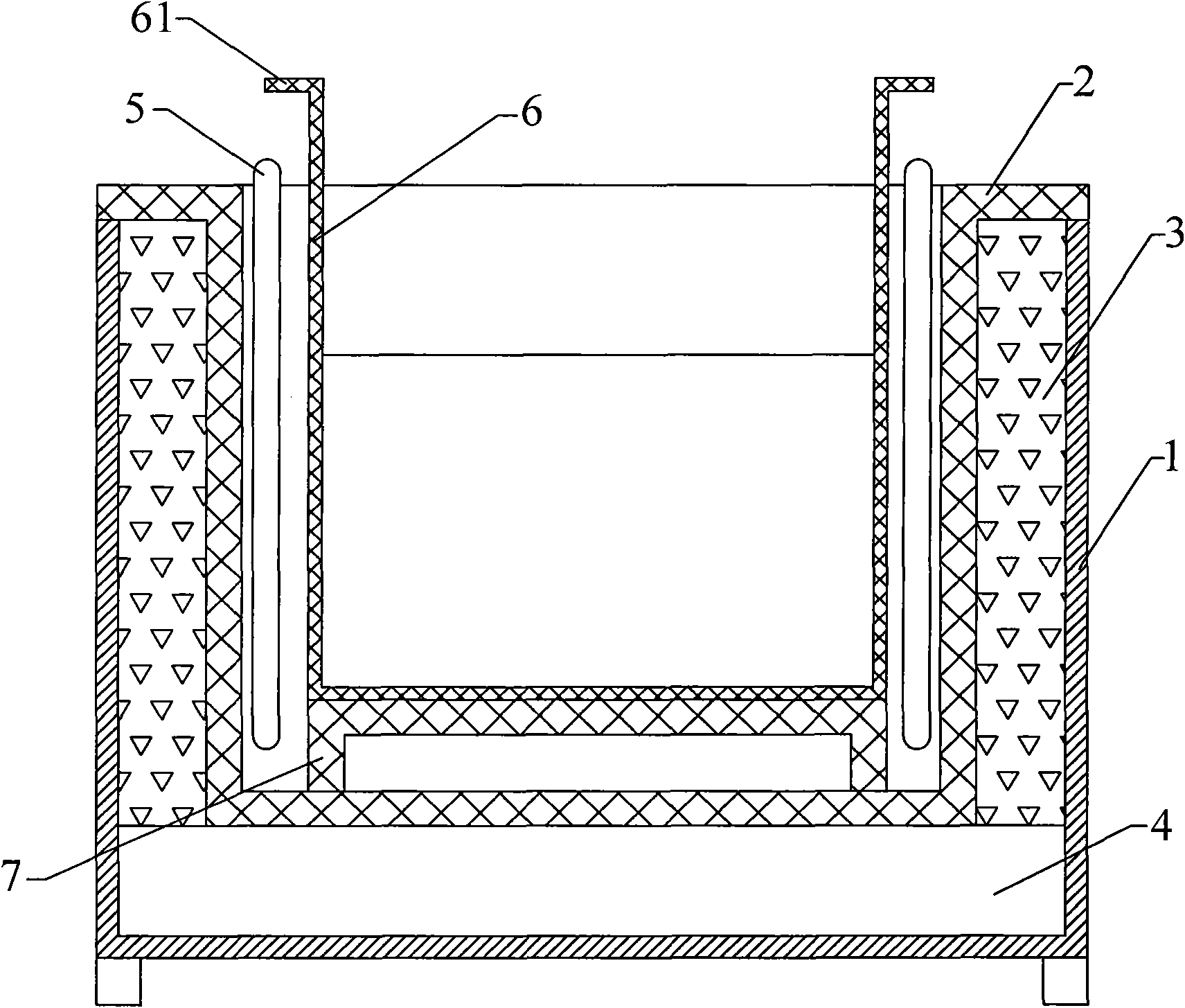

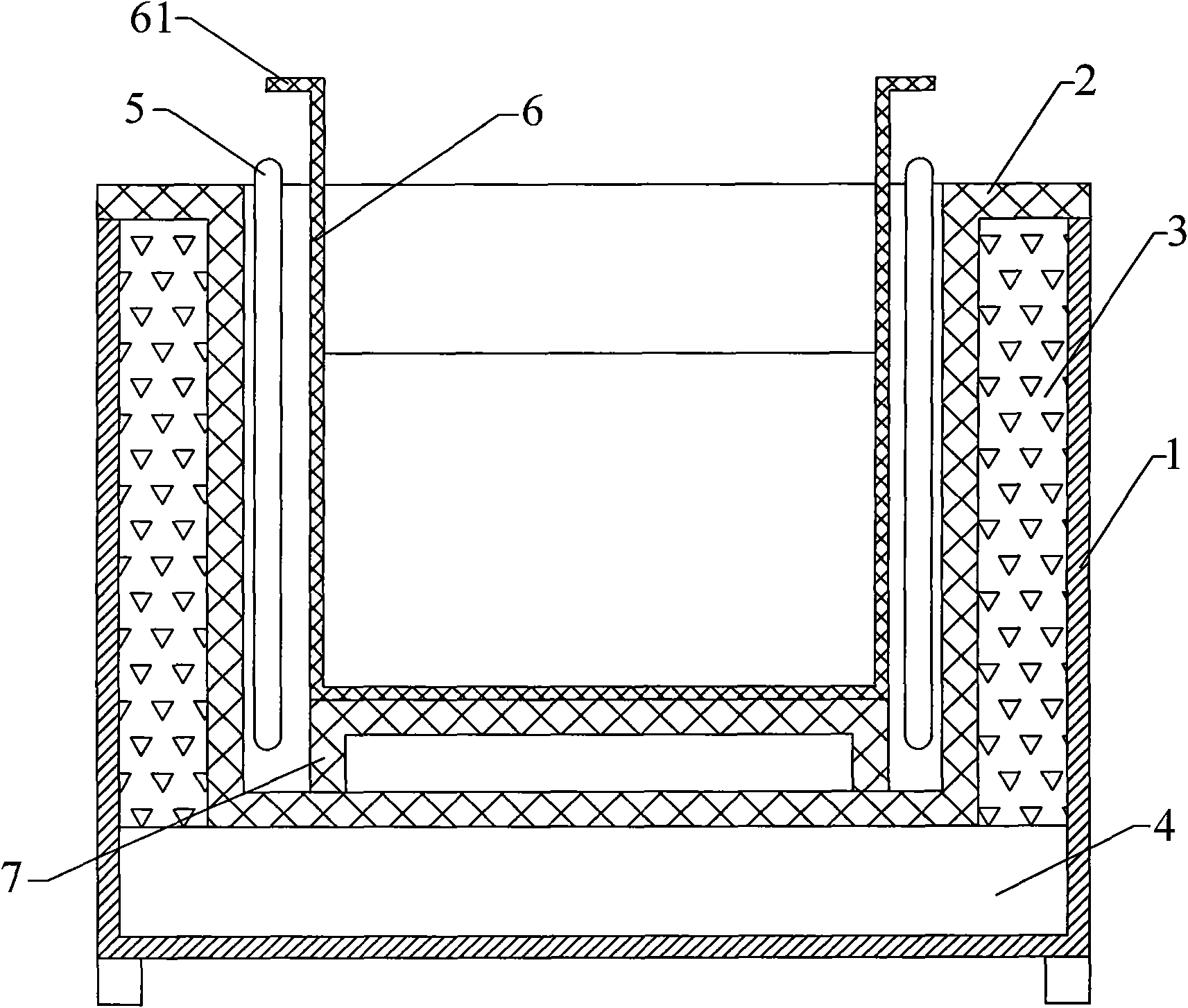

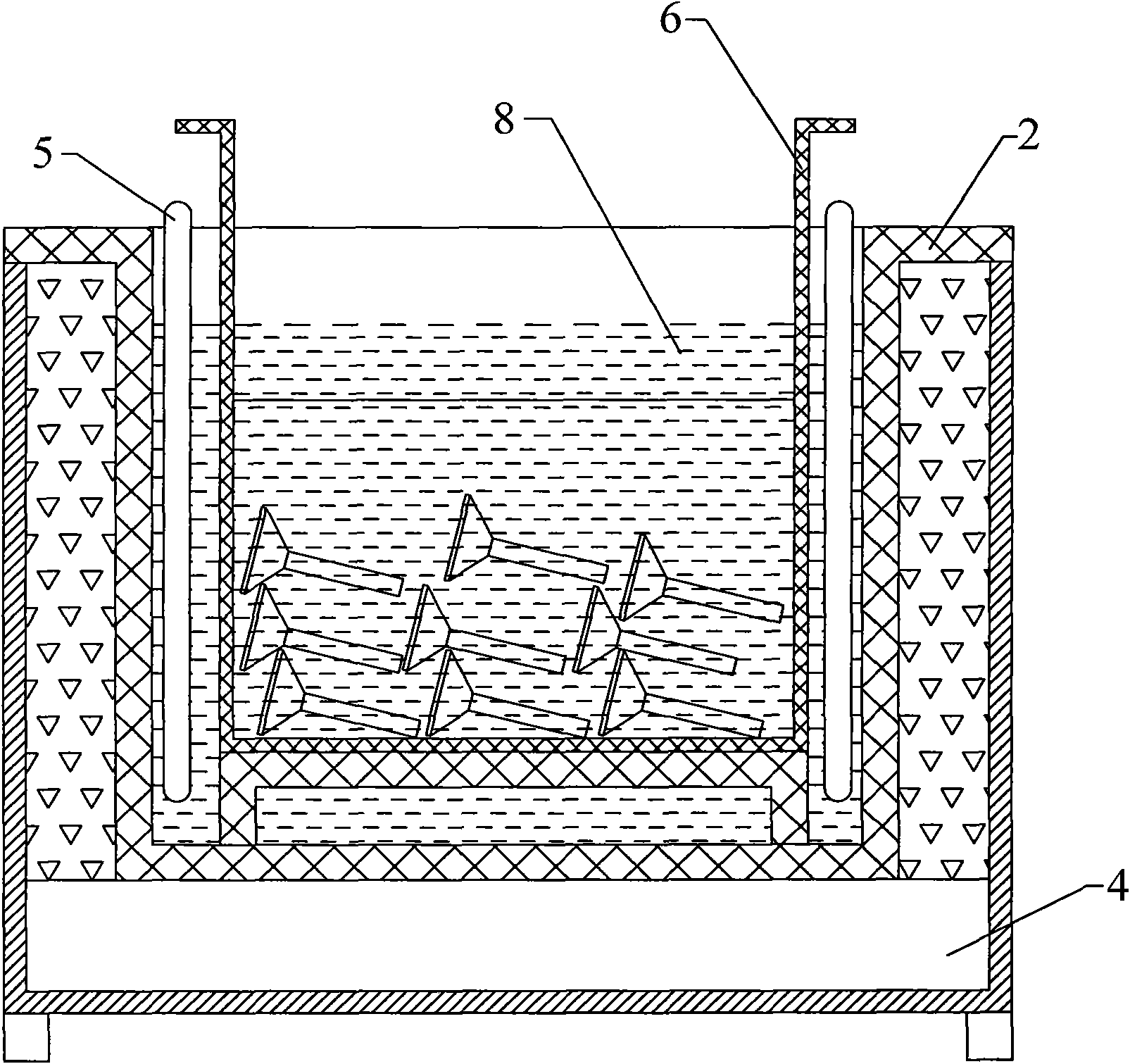

[0020] As shown in Figure 1, the rapid derusting device of the present invention includes an outer sleeve 1 and an inner lining groove 2. The inner lining groove 2 is arranged inside the outer sleeve 1, and between the outer sleeve 1 and the inner lining groove 2. Thermal insulation polyurethane insulation layer 3.

[0021] An ultrasonic vibrating plate 4 is provided at the inner bottom end of the outer casing groove 1, and the ultrasonic vibrating plate 4 is in contact with the bottom of the inner lining groove 2 and includes two parts: an ultrasonic vibrating plate and an ultrasonic generator.

[0022] A number of heating tubes 5 are arranged inside the lining tank 2. The heating tubes 5 are evenly arranged near the peripheral end of the inner wall of the lining tank 2 and the outer wall of each heating tube 5 is wrapped with a polytetrafluoroethylene anti-corrosion layer, and The outer casing 1 is provided with a temperature control timing mechanism for controlling the heating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com