Method and equipment for utilizing ultrafast lasers for frequency modulation of quartz crystals

A technology of quartz crystal and ultra-fast laser, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem that the production speed and frequency adjustment error range are greatly affected by the quality of processing personnel, affecting the frequency stability of crystal products, and affecting The quality of quartz crystal components and other issues can be reduced to reduce the temperature drift characteristics of resonant frequency, realize the fine adjustment of a wide range of frequencies, and improve the real-time measurement accuracy of processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

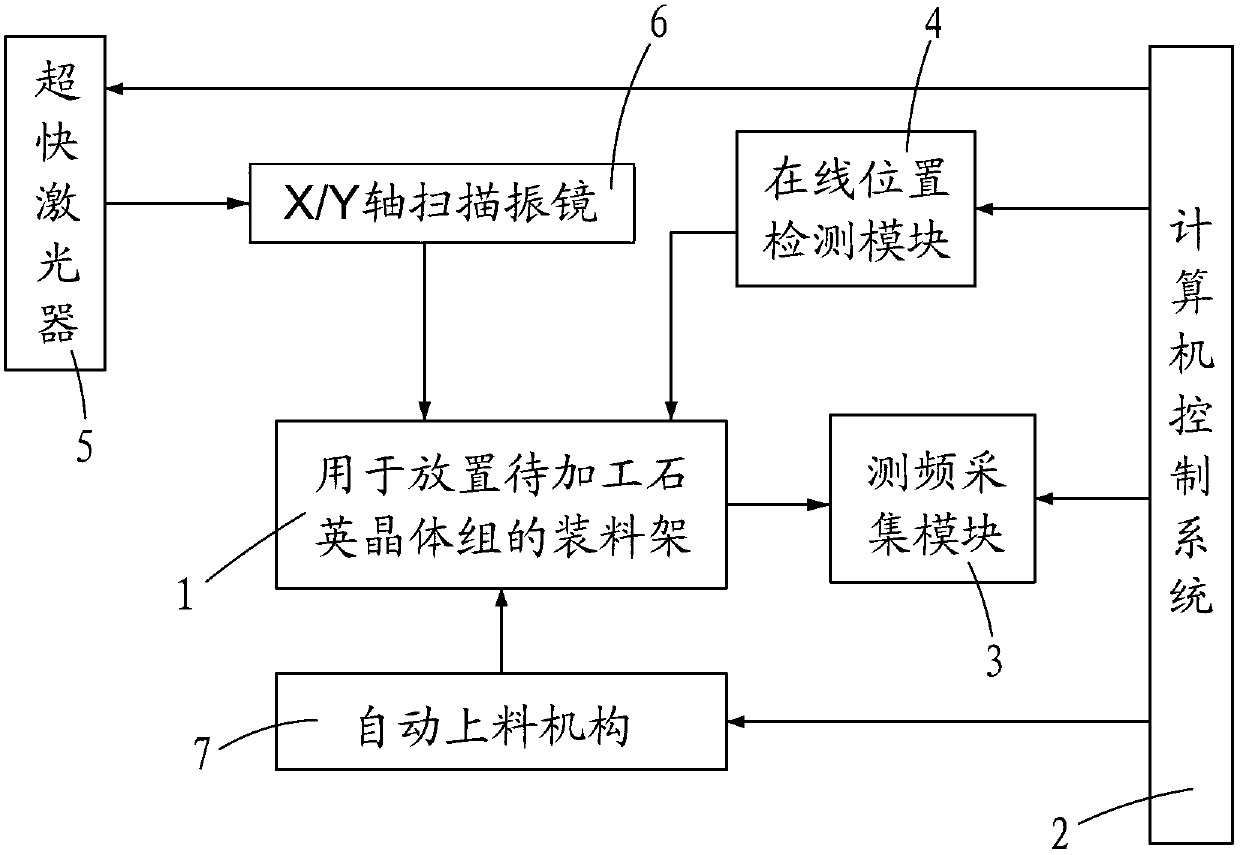

[0028] see figure 1 As shown, a device for frequency modulation of quartz crystals using ultrafast lasers of the present invention includes a charging rack 1 for placing quartz crystal groups to be processed and a computer control system 2, and the device also includes a device for measuring the resonance of quartz crystals. A frequency measurement and acquisition module 3 of frequency, the frequency measurement and acquisition module 3 is arranged on the charging rack 1, and is electrically connected with the computer control system 2;

[0029] An online position detection module 4 for detecting the position of the quartz crystal, the online position detection module 4 is arranged above the charging rack 1, and is electrically connected with the computer control system 2;

[0030] An ultrafast laser 5, the ultrafast laser 5 projects the laser light generated on the quartz crystal through an X / Y axis scanning galvanometer 6 for etching, and the ultrafast laser 5 is electricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com