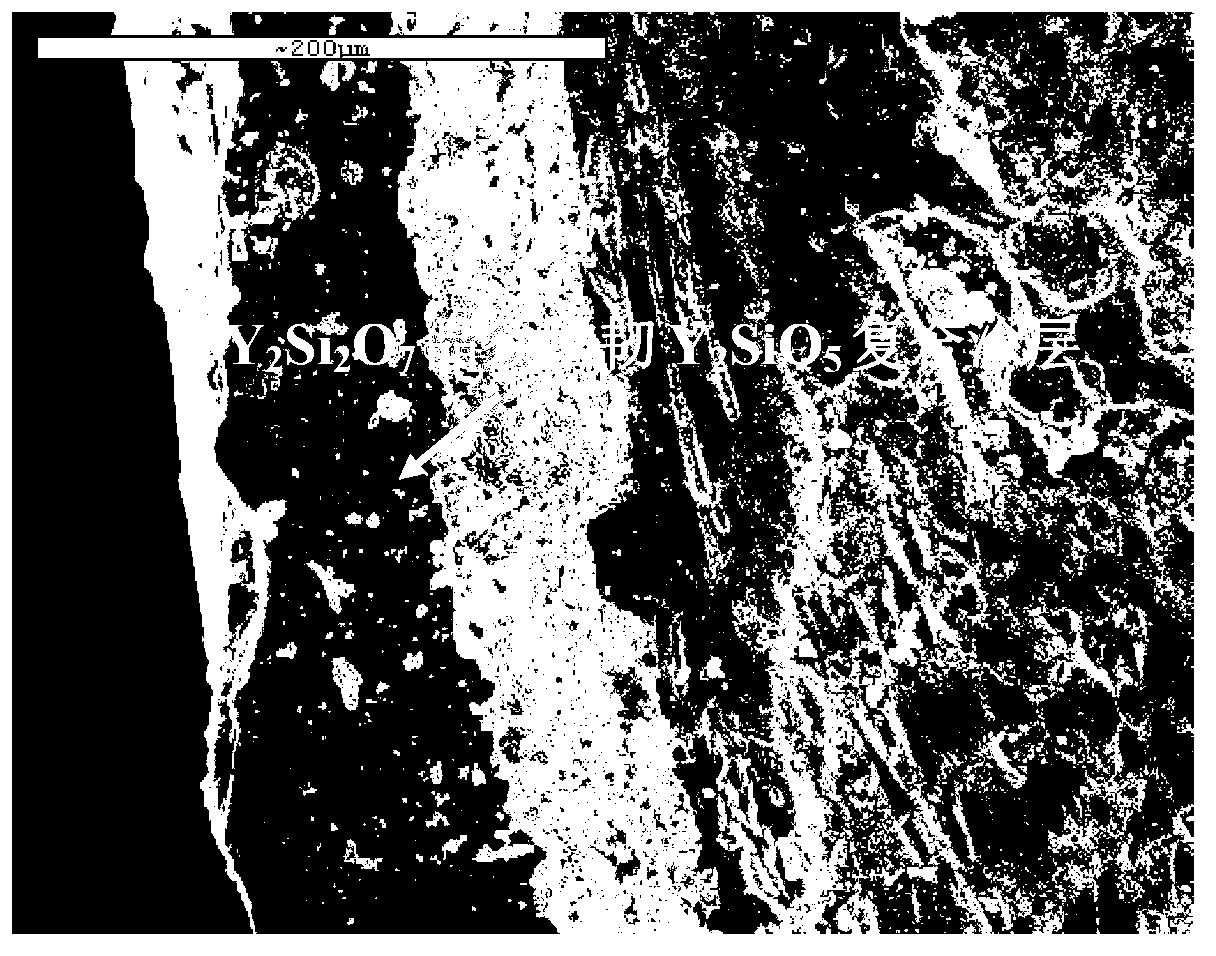

Preparation method of Y2Si2O7 whisker toughened Y2SiO5 composite coating

A composite coating and whisker technology, which is applied in the field of preparation of high-temperature anti-oxidation coatings, can solve the problems of thermal expansion coefficient difference, substrate oxidation, micro-cracks and holes, etc. The effect of microcracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: C / C composite material pretreatment:

[0034] 1) Take the 2D-carbon / carbon composite material used for aircraft brake pads and process it into 20×20×20mm 3 The cube, and its surface treatment of grinding and chamfering, the chamfering is 30°;

[0035] 2) Then use deionized water and absolute ethanol to ultrasonically clean 4 times respectively, the ultrasonic time for each cleaning is 10min, the ultrasonic power is 80W, and finally dry in an electric blast drying oven at 50°C.

[0036] Step 2: Prepare SiC porous inner coating on the surface of C / C composite substrate by embedding method

[0037] 1) First, take commercially available analytically pure Si powder, C powder and WO with a particle size of 20-30 μm 3 Powder, according to Si powder: C powder: WO 3 Powder=3:4.5:0.5 mass ratio to prepare embedding powder, then put the pretreated carbon / carbon composite material into graphite crucible, and embed it in the embedding powder;

[0038] 2) Next, put the gr...

Embodiment 2

[0051] Step 1: C / C composite material pretreatment:

[0052] 1) Take the 2D-carbon / carbon composite material used for aircraft brake pads and process it into 23×23×23mm 3 The cube, and its surface treatment of grinding and chamfering, the chamfering is 35°;

[0053] 2) Then use deionized water and absolute ethanol to ultrasonically clean 3 times respectively, the ultrasonic time of each cleaning is 20min, the ultrasonic power is 100W, and finally dry in an electric blast drying oven at 55°C.

[0054] Step 2: Prepare SiC porous inner coating on the surface of C / C composite substrate by embedding method

[0055] 1) First, take commercially available analytically pure Si powder, C powder and WO with a particle size of 20-30 μm 3 Powder, according to Si powder: C powder: WO 3 Powder = 4:4:0.8 mass ratio to prepare embedding powder, then put the pretreated carbon / carbon composite material into a graphite crucible, and embed it in the embedding powder;

[0056] 2) Next, put the ...

Embodiment 3

[0068] Step 1: C / C composite material pretreatment:

[0069] 1) Take the 2D-carbon / carbon composite material used for aircraft brake pads and process it into 25×25×25mm 3 The cube, and its surface treatment of grinding and chamfering, the chamfering is 40°;

[0070] 2) Then use deionized water and absolute ethanol to ultrasonically clean 5 times respectively, the ultrasonic time of each cleaning is 30min, the ultrasonic power is 120W, and finally dry in an electric blast drying oven at 60°C.

[0071] Step 2: Prepare SiC porous inner coating on the surface of C / C composite substrate by embedding method

[0072] 1) First, take commercially available analytically pure Si powder, C powder and WO with a particle size of 20-30 μm 3 Powder, according to Si powder: C powder: WO 3 Powder=3.5:5:1.0 mass ratio to prepare embedding powder, then put the pretreated carbon / carbon composite material into graphite crucible, and embed it in the embedding powder;

[0073] 2) Next, put the gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com