Multiferroic composite material with magneto-dielectric effect and preparation method thereof

A multiferroic and electric effect technology, applied in the field of ceramic compositions, achieves the effects of stable performance, simple preparation process, and wide application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

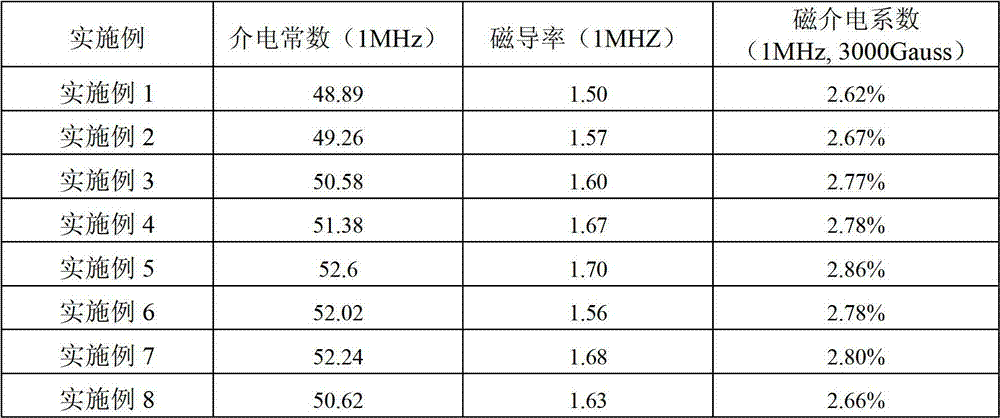

Examples

Embodiment 1

[0023] (1) Na 2 CO 3 and Nb 2 o 5 , NiO and Fe 2 o 3 According to the stoichiometric formula NaNbO 3 and NiFe 2 o 4 Dosing, NaNbO 3 and NiFe 2 o 4 The molar ratio is 1:1, put 14g of mixed powder into the polyester tank, and add the material: deionized water: zirconium balls into the polyester tank in the ratio of 1:1:1.5 mass ratio, in the planetary Ball milling on the ball mill for 4 hours, the speed of the ball mill is 1000 rpm;

[0024] (2) Place the ball-milled raw materials in a drying oven, dry them at 120°C, and pass them through a 40-mesh sieve;

[0025] (3) Put the dried and sieved powder into a medium-temperature furnace, pre-fire at 900°C, and keep it warm for 4 hours;

[0026] (4) The pre-burned powder is added with a paraffin wax binder with a mass percentage of 8% for granulation. After passing through an 80-mesh sieve, use a powder tablet press to compress the powder into a diameter of 20mm under a pressure of 4MPa. A green body with a thickness of ...

Embodiment 2

[0030] (1) Na 2 CO 3 and Nb 2 o 5 , NiO and Fe 2 o 3 According to the stoichiometric formula NaNbO 3 and NiFe 2 o 4 Dosing, NaNbO 3 and NiFe 2 o 4 The molar ratio is 1:1, put 14g of mixed powder into the polyester tank, and add the material: deionized water: zirconium balls into the polyester tank in the ratio of 1:1:1.5 mass ratio, in the planetary Ball milling on the ball mill for 12 hours; the rotating speed is 1000 rpm;

[0031] (2) Place the ball-milled raw materials in a drying oven, dry them at 100°C, and pass them through a 40-mesh sieve;

[0032] (3) Put the dried and sieved powder into a medium-temperature furnace, pre-burn it at 1150°C, and keep it warm for 4 hours;

[0033] (4) The pre-burned powder is added with a paraffin wax binder with a mass percentage of 8% for granulation. After passing through an 80-mesh sieve, use a powder tablet press to compress the powder into a diameter of 20mm under a pressure of 4MPa. A green body with a thickness of 5 m...

Embodiment 3

[0037] (1) Na 2 CO 3 and Nb 2 o 5 , NiO and Fe 2 o 3 According to the stoichiometric formula NaNbO 3 and NiFe 2 o 4 Dosing, NaNbO 3 and NiFe 2 o 4 The molar ratio is 1:1, put 14g of mixed powder into the polyester tank, and add the material: deionized water: zirconium balls into the polyester tank in the ratio of 1:1:1.5 mass ratio, in the planetary Ball milling on the ball mill for 24 hours; the speed is 1000 rpm;

[0038] (2) The raw materials after ball milling are placed in a drying oven, dried at 120°C, and then passed through a 40-mesh sieve;

[0039] (3) Put the dried and sieved powder into a medium-temperature furnace, pre-fire it at 1100°C, and keep it warm for 6 hours;

[0040] (4) The pre-burned powder is added with a paraffin wax binder with a mass percentage of 8% for granulation. After passing through an 80-mesh sieve, use a powder tablet press to compress the powder into a diameter of 20mm under a pressure of 4MPa. A green body with a thickness of 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com