Si (Silicon)-base III nitride epitaxial wafer without microcracks in surface

A microcrack and nitride technology, applied in the field of Si-based III-nitride epitaxial wafers and III-nitride heterojunction epitaxial wafers, can solve the problem of reduced material growth quality, intensified pre-reaction, and superlattice interface mismatch. Dislocation and other problems, to achieve the effect of improving crystal quality, increasing growth rate, and improving surface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

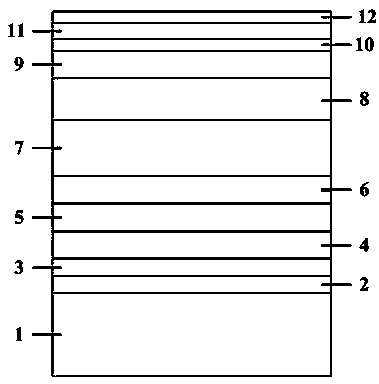

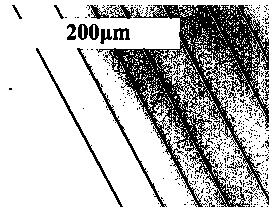

[0039] refer to figure 1 , the growth of microcrack-free Si-based III-nitride epitaxial wafer structures, using the metal-organic chemical vapor deposition (MOCVD) method as an example,

[0040] 1) A 111-sided single-crystal Si with a diameter of 101.6 mm is used as the substrate 1, and the oxide film on the surface of the Si substrate is removed by a hydrofluoric acid-based etching solution before the growth of the nitride epitaxial layer. Then, it is placed in the reaction chamber of the MOCVD apparatus.

[0041] 2) Heating the Si substrate in a hydrogen atmosphere at a pressure of 6.65kPa in the reaction chamber for 1 to 1000 o C, thermal annealing for 10min.

[0042] 3) Keep the reaction chamber pressure constant and lower the substrate temperature to 900 o C, Ammonia gas with a flow rate of 10 L / min and trimethylaluminum (TMA) with a flow rate of 86 μmol / min are injected to grow an AlN nucleation layer 2 with a thickness of 100 nm, and the growth time is 1800 s. Then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com