Yttrium iron garnet film and preparation method thereof

A technology of yttrium-iron garnet and thin film, which is applied in the field of yttrium-iron garnet thin film and its preparation, can solve the problems of inability to accurately control the stoichiometric ratio, high requirements for preparation conditions, expensive physical method equipment, etc., and achieve excellent magnetic properties, Low environmental pollution and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

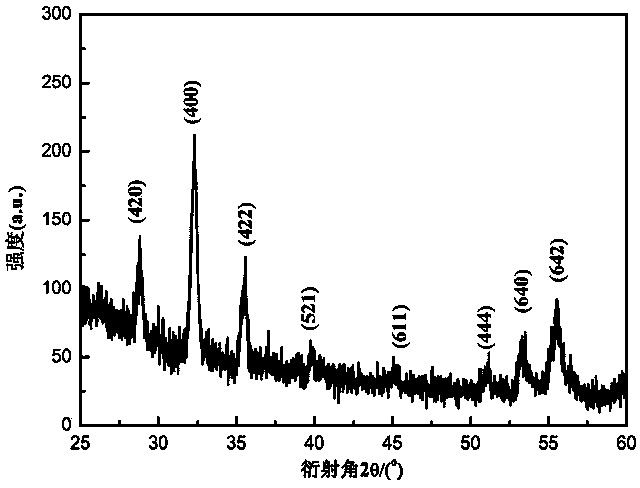

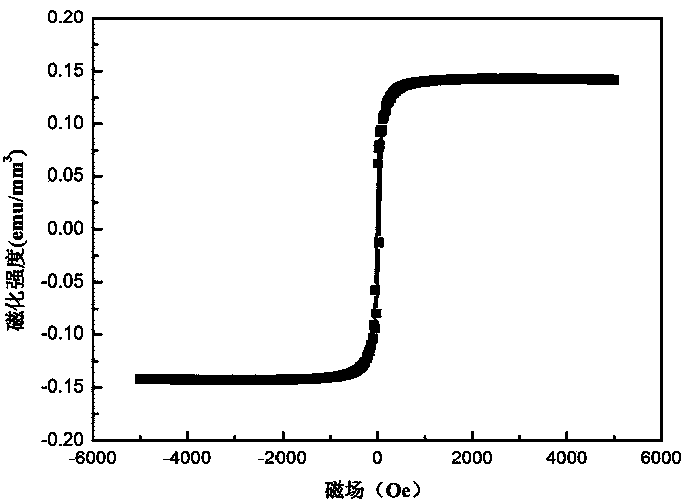

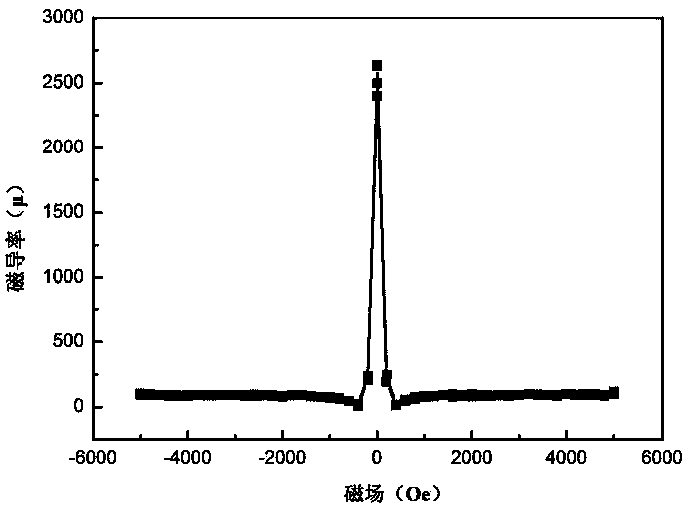

[0048] The preparation of described yttrium iron garnet thin film comprises following specific steps:

[0049] a) Preparation of precursor solution

[0050] First, the solute yttrium oxide and ferric nitrate are dissolved in a mixed solvent of acetic acid and deionized water according to the ratio, heated to 60-80°C to dissolve completely, and then acetylacetone is added for complexation, and the concentration of yttrium in the mixed solution is controlled at 0.15- 0.75M / L; after the solution is completely reacted, it is allowed to stand at room temperature for 48-72 hours, and then filtered with a 0.2-micron microporous membrane to obtain a stable yttrium-iron-garnet (YIG) precursor solution;

[0051] b) Film preparation

[0052] The prepared precursor solution was added dropwise at a uniform speed on the clean and high-speed rotating substrate, and the solvent evaporated rapidly to obtain a gel film; the gel film was placed in an annealing furnace for segmental heat treatme...

Embodiment 1

[0062] a) cleaning of the silicon substrate;

[0063] First place the silicon wafer in an acetone solution for 10 minutes of ultrasonic cleaning, then place it in an ethanol solution for 10 minutes of ultrasonic cleaning, and finally in deionized water for 10 minutes of ultrasonic cleaning, the substrate is cleaned and dried for later use;

[0064] b) Preparation of precursor solution

[0065] First, dissolve yttrium oxide and ferric nitrate with a molar ratio of Y:Fe of 3:5 in a mixed solvent of acetic acid and deionized water, heat to 60-80°C to completely dissolve the solute, and finally add acetylacetone complexing agent and continue heating Make the solution react completely, the ratio of acetic acid, acetylacetone and water is 30:15:5, the concentration of yttrium element in the solution is 0.15M / L, place the obtained deep red solution at room temperature for 48-72h; use a 0.2 micron microporous filter Membrane filtration solution can obtain stable YIG yttrium iron garn...

Embodiment 2

[0069] The difference between this embodiment and embodiment 1 is that: finally annealing is performed at a high temperature of 750° C. for 30 minutes, and the rest of the content is exactly the same as that of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com